Current location:Home > blue used cars >

blue used cars

2025-08-15 21:14

2025-08-15 20:58

...

2025-08-15 20:57

2025-08-15 20:51

2025-08-15 20:41

2025-08-15 20:03

The manufacturing of galvanized iron wire mesh typically involves several key steps. Initially, high-quality steel or iron wire is sourced, which is then drawn through a series of dies to achieve the desired diameter. After the wire is prepared, it undergoes galvanization, where it is immersed in molten zinc or subjected to a hot-dip galvanization process. This results in a robust protective coat that enhances corrosion resistance.

...

2025-08-15 19:53

2025-08-15 19:28

2025-08-15 19:18

2025-08-15 18:43

Latest articles

In the collectible metal lunch box market, several manufacturers stand out for their commitment to quality, design, and innovation

. Companies like Loungefly, The Tin Box Company, and Schylling have made significant strides in the industry, each contributing unique designs and thematic collections.In industrial environments, stainless steel wire mesh plays a crucial role in protecting workers and equipment. It is used as guarding mesh to prevent accidents caused by falling objects or flying debris It is used as guarding mesh to prevent accidents caused by falling objects or flying debris It is used as guarding mesh to prevent accidents caused by falling objects or flying debris It is used as guarding mesh to prevent accidents caused by falling objects or flying debris

It is used as guarding mesh to prevent accidents caused by falling objects or flying debris It is used as guarding mesh to prevent accidents caused by falling objects or flying debris stainless steel wire mesh price. Its durability and high visibility make it an effective safety measure in factories, construction sites, and other industrial settings.

stainless steel wire mesh price. Its durability and high visibility make it an effective safety measure in factories, construction sites, and other industrial settings.

It is used as guarding mesh to prevent accidents caused by falling objects or flying debris It is used as guarding mesh to prevent accidents caused by falling objects or flying debris

It is used as guarding mesh to prevent accidents caused by falling objects or flying debris It is used as guarding mesh to prevent accidents caused by falling objects or flying debris stainless steel wire mesh price. Its durability and high visibility make it an effective safety measure in factories, construction sites, and other industrial settings.

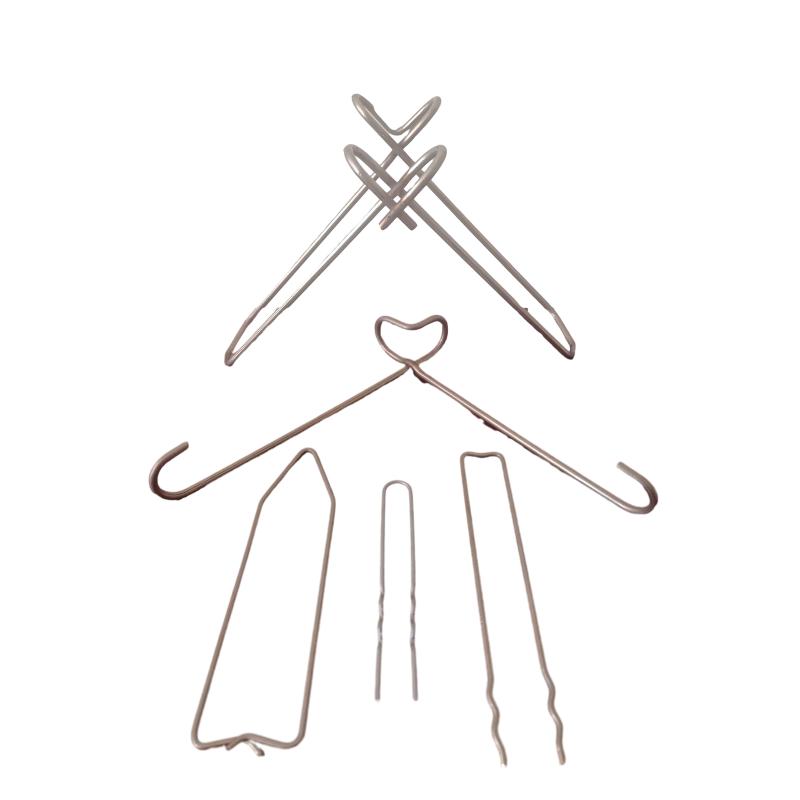

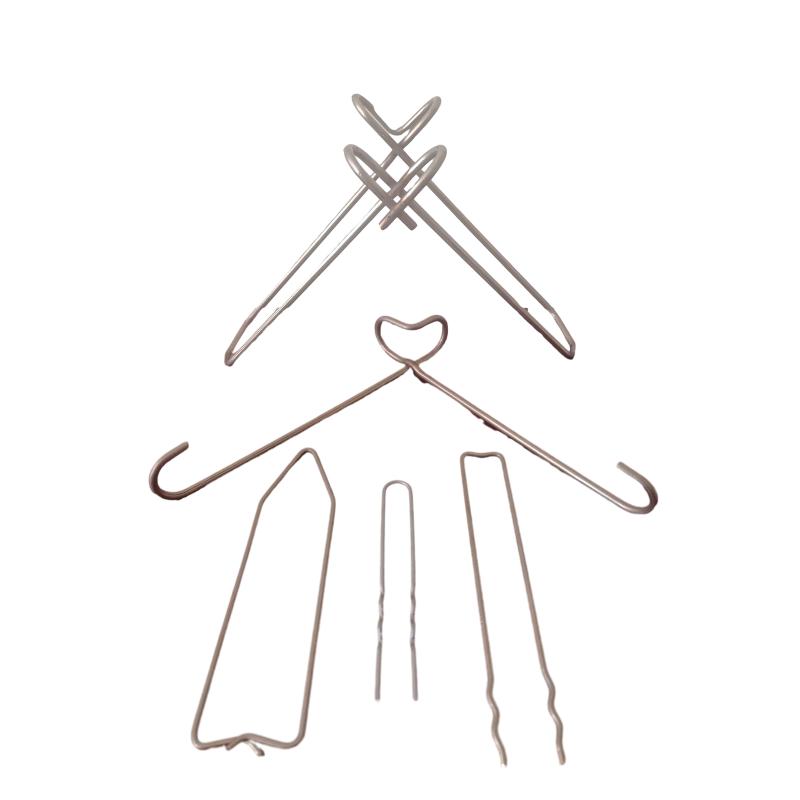

stainless steel wire mesh price. Its durability and high visibility make it an effective safety measure in factories, construction sites, and other industrial settings.In addition to providing structural support, cavity ties also help to prevent the buildup of moisture within the cavity

cavity ties. When moisture accumulates within the cavity wall, it can lead to a range of problems, including mold growth, decay of the wall materials, and reduced thermal insulation properties. By allowing for proper ventilation and drainage within the cavity, cavity ties help to prevent these issues and ensure the long-term durability of the wall.

cavity ties. When moisture accumulates within the cavity wall, it can lead to a range of problems, including mold growth, decay of the wall materials, and reduced thermal insulation properties. By allowing for proper ventilation and drainage within the cavity, cavity ties help to prevent these issues and ensure the long-term durability of the wall.

In addition to their ease of use and versatility, temporary cattle fences also help improve pasture health and productivity. By rotating cattle through different grazing areas, farmers can prevent overgrazing and ensure more even distribution of forage

temporary cattle fence. This not only benefits the cattle by providing them with a diverse and nutritious diet but also promotes regrowth and sustainability of the pasture.

temporary cattle fence. This not only benefits the cattle by providing them with a diverse and nutritious diet but also promotes regrowth and sustainability of the pasture.

Moreover, wire mesh manufacturers also contribute to sustainability efforts wire mesh manufacturers. Many companies are adopting eco-friendly practices, recycling scrap metal and using energy-efficient machinery. This not only reduces waste but also lowers the carbon footprint of the manufacturing process.

wire mesh manufacturers. Many companies are adopting eco-friendly practices, recycling scrap metal and using energy-efficient machinery. This not only reduces waste but also lowers the carbon footprint of the manufacturing process.

wire mesh manufacturers. Many companies are adopting eco-friendly practices, recycling scrap metal and using energy-efficient machinery. This not only reduces waste but also lowers the carbon footprint of the manufacturing process.

wire mesh manufacturers. Many companies are adopting eco-friendly practices, recycling scrap metal and using energy-efficient machinery. This not only reduces waste but also lowers the carbon footprint of the manufacturing process.