best used car dealerships in mesa az

Welding is another critical step in the manufacturing process, where pieces are fused together to create a sturdy structure. Factories today have upgraded their welding techniques, utilizing robotic welders for consistency and strength. After assembly, the metal surfaces undergo cleaning and priming to prepare for painting, which protects against rust and enhances appearance. Finally, drawers are added, and the entire unit is subjected to quality control checks to ensure durability and functionality.

metal tool boxes with drawers factories

Manufacturers in the galvanized color coating plant sector are continuously innovating to enhance efficiency and product quality. Incorporating advanced technologies such as automation and robotics has streamlined production processes, reducing labor costs and minimizing human error. Additionally, the use of eco-friendly materials and paints aligns with global sustainability goals, allowing manufacturers to cater to environmentally-conscious consumers.

Leading suppliers will often have a well-structured catalog that includes detailed specifications for the sizes and types of sheets available. Some may even offer online tools that allow customers to input their specific requirements and receive recommendations for the appropriate sizes and materials.

steel roof sheet sizes suppliers

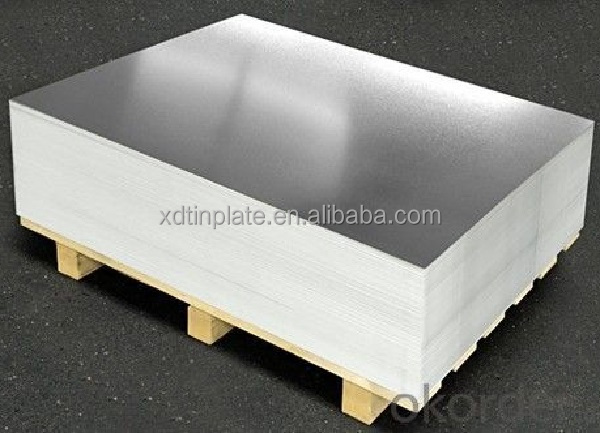

Leading manufacturers typically offer a range of galvanizing processes, such as hot-dip galvanizing or electro-galvanizing. Hot-dip galvanizing involves immersing the metal in molten zinc, resulting in a thicker coating that provides superior corrosion resistance. On the other hand, electro-galvanizing applies a thin layer of zinc through an electrochemical process, often resulting in a more polished finish, but may not offer the same level of protection as hot-dip galvanization.

galvanized iron sheet thickness manufacturers

Prefabricated steel workshops also provide a high degree of customization. Businesses can design their workshops to meet specific operational needs, whether that involves special dimensions, layouts, or features like reinforced flooring for heavy machinery. Furthermore, as companies grow or change their needs, these workshops can be easily expanded or modified. This flexibility allows businesses to adapt to changing market conditions without incurring substantial costs.

prefabricated steel workshop