Current location:Home > best credit union for used car loan >

best credit union for used car loan

2025-08-15 08:59

2025-08-15 08:42

2025-08-15 08:39

2025-08-15 08:00

2025-08-15 07:49

2025-08-15 07:35

2025-08-15 07:29

2025-08-15 07:05

2025-08-15 06:51

2025-08-15 06:38

Latest articles

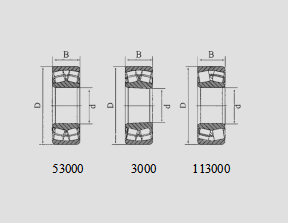

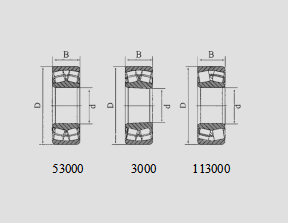

Moreover, these bearings are available in different designs, including flat seat and spherical seat types, catering to specific application requirements double row thrust ball bearing. The flat seat variant is suitable for applications with uniform load distribution, while the spherical seat type offers self-aligning capabilities, accommodating misalignments in the shaft and housing.

double row thrust ball bearing. The flat seat variant is suitable for applications with uniform load distribution, while the spherical seat type offers self-aligning capabilities, accommodating misalignments in the shaft and housing.

double row thrust ball bearing. The flat seat variant is suitable for applications with uniform load distribution, while the spherical seat type offers self-aligning capabilities, accommodating misalignments in the shaft and housing.

double row thrust ball bearing. The flat seat variant is suitable for applications with uniform load distribution, while the spherical seat type offers self-aligning capabilities, accommodating misalignments in the shaft and housing.The design of needle thrust roller bearings also reduces friction and heat generation, resulting in improved efficiency and longer service life. This is particularly important in high-speed applications where friction can lead to premature wear and failure. The use of needle rollers also helps distribute load evenly across the bearing, reducing stress on individual components and ensuring smooth operation.

One of the key advantages of bearing manufacturing machines is their ability to produce bearings with high levels of accuracy. These machines use advanced sensors and controls to ensure that each bearing meets the strict tolerances required for its intended application. This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line

This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line bearing manufacturing machine.

bearing manufacturing machine.

This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line

This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line This level of precision not only improves the performance of the final product but also reduces the risk of costly failures down the line bearing manufacturing machine.

bearing manufacturing machine.