used car lots lancaster pa

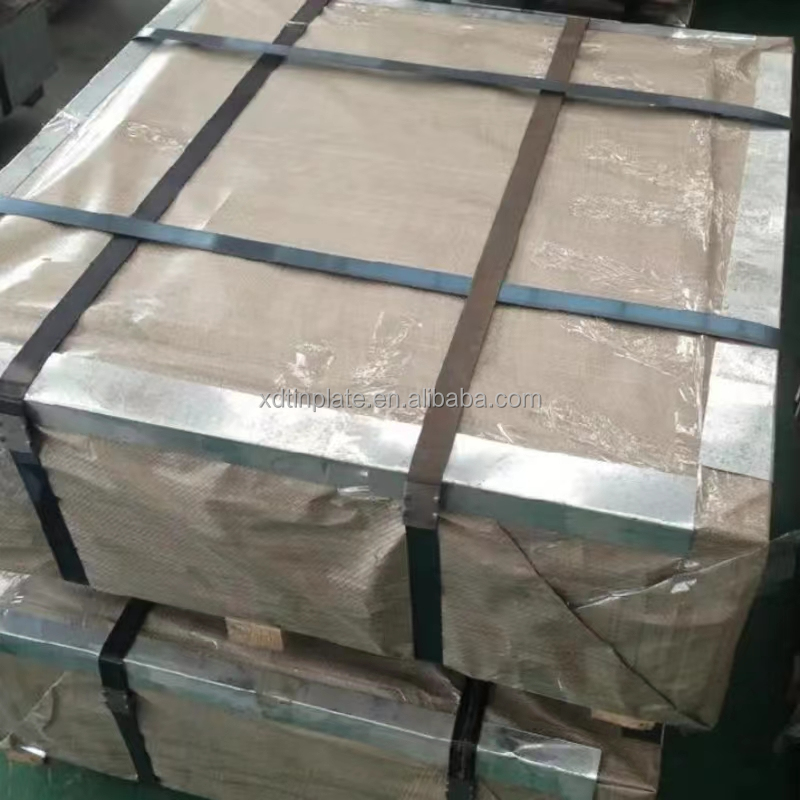

When it comes to manufacturers of galvanized iron sheets, various factors can influence the quality and reliability of their products. Established manufacturers often adopt stringent quality control measures to ensure that their products meet industry standards. They employ advanced coating technology and utilize high-quality raw materials to produce sheets that can withstand harsh environmental conditions.

Additionally, many vintage metal lunch boxes featured slogans or phrases in both Chinese and English, reflecting a blend of cultures during a time of globalization

. This not only catered to a broader audience but also highlighted a moment in history when cultural exchange was becoming more prevalent.china vintage metal lunch boxes

Leading manufacturers typically offer a range of galvanizing processes, such as hot-dip galvanizing or electro-galvanizing. Hot-dip galvanizing involves immersing the metal in molten zinc, resulting in a thicker coating that provides superior corrosion resistance. On the other hand, electro-galvanizing applies a thin layer of zinc through an electrochemical process, often resulting in a more polished finish, but may not offer the same level of protection as hot-dip galvanization.

galvanized iron sheet thickness manufacturers

Furthermore, the aesthetic appeal of tin boxes cannot be overlooked. Available in various shapes, sizes, and designs, they offer brands the opportunity to stand out on the shelves. Customization options are plentiful, allowing companies to incorporate logos, colors, and designs that reflect their brand identity. This flexibility in design not only enhances product visibility but also contributes to a positive consumer experience, leading to increased brand loyalty.

tin box supplier suppliers