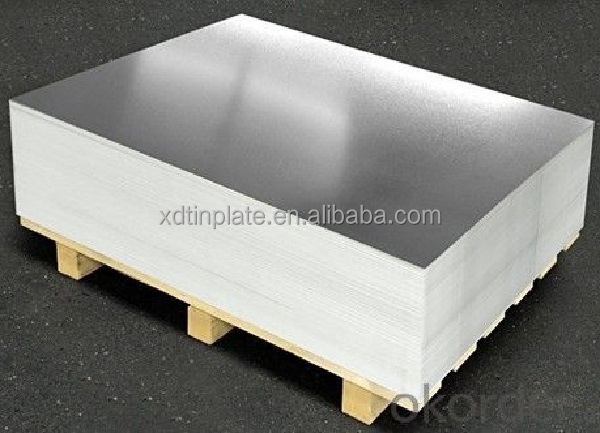

The rise of large metal boxes factories can be attributed to various technological advancements that have revolutionized the manufacturing process

. Automation and robotics have significantly increased production efficiency, allowing factories to produce large quantities of metal boxes in a relatively short amount of time. This not only reduces labor costs but also minimizes the margin of error, leading to high-quality products that meet industry standards.large metal boxes factories