used car dealerships in marietta ohio

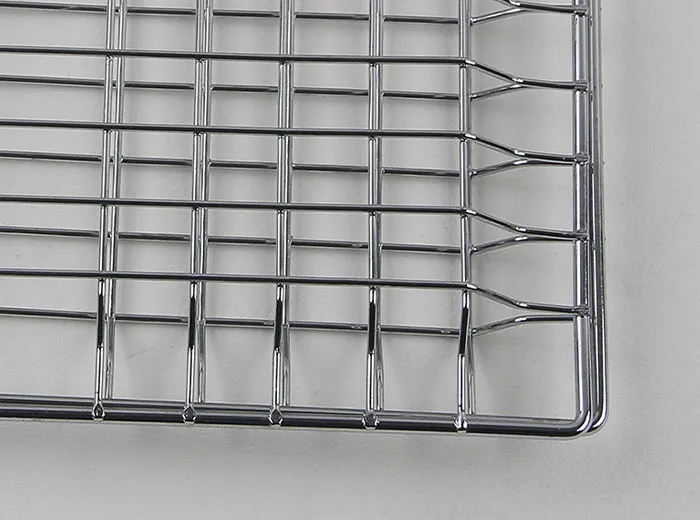

Today, tin plate ceiling manufacturers combine traditional craftsmanship with cutting-edge technology. The process begins with high-quality steel sheets that are coated with a layer of tin to prevent rust and corrosion. Manufacturers have started integrating advanced techniques such as computerized laser cutting to create intricate designs, ensuring precision and consistency. This modern approach allows for customizable options that cater to contemporary tastes while retaining the classic appeal of tin ceilings.

tin plate ceiling manufacturers

Once produced, the foam sheets are cut to size and prepared for distribution. Quality control is integral to the process, which includes testing for insulation effectiveness, durability, and resistance to various environmental factors. It is essential for manufacturers to comply with industry standards and regulations concerning safety and environmental impact, which adds an additional layer of integrity to the production process.

foam roof sheet factories

Another popular option is the foam or straw base, which offers a more structured form for wreath-making. Foam bases are particularly useful for those who prefer a more polished look. They allow for easier attachment of materials, making them ideal for intricate designs or heavy embellishments. Straw bases, on the other hand, provide a lightweight alternative that is also easy to customize. Both options are fantastic for crafters looking to create a wreath that stands out.

wreath base