samsung nx mini ev-nxf1zzb4ius

A cap sheet is a waterproof material used in flat roofing systems, typically installed on the top layer of the roof to provide protection. It forms a barrier against weather elements, ensuring that water cannot penetrate through to the structure beneath. This is crucial as leaks can lead to devastating damage, including rot, mold, and structural weakness.

Historically, tin was favored for its lightweight nature and resistance to corrosion, making it an ideal choice for roofing. The traditional tin roofs, often made from galvanized steel, have transformed into a variety of modern options including pre-painted, textured, and even reflective styles that cater to diverse architectural needs. As consumers become more environmentally conscious, tin metal roofing manufacturers have adapted their products to meet the demands for energy efficiency and sustainability.

Moreover, manufacturers are constantly innovating to enhance the properties of tin plate sheet metal. Advances in coating techniques, for instance, have led to the development of tin plates with improved corrosion resistance and mechanical strength. These innovations are driven by the need for materials that perform well under various environmental conditions while also being cost-effective for manufacturers and consumers.

tin plate sheet metal manufacturers

Another advantage of China Meridian metal roofing is its aesthetic versatility. Available in a wide range of colors, finishes, and styles, metal roofing can complement the architecture of any home, enhancing its curb appeal. Whether you prefer a sleek, modern look or a more traditional appearance, China Meridian offers various designs that can meet your aesthetic needs. Homeowners can choose from standing seam panels, metal shingles, or tiles, enabling them to achieve their desired look without compromising on functionality.

china meridian metal roofing

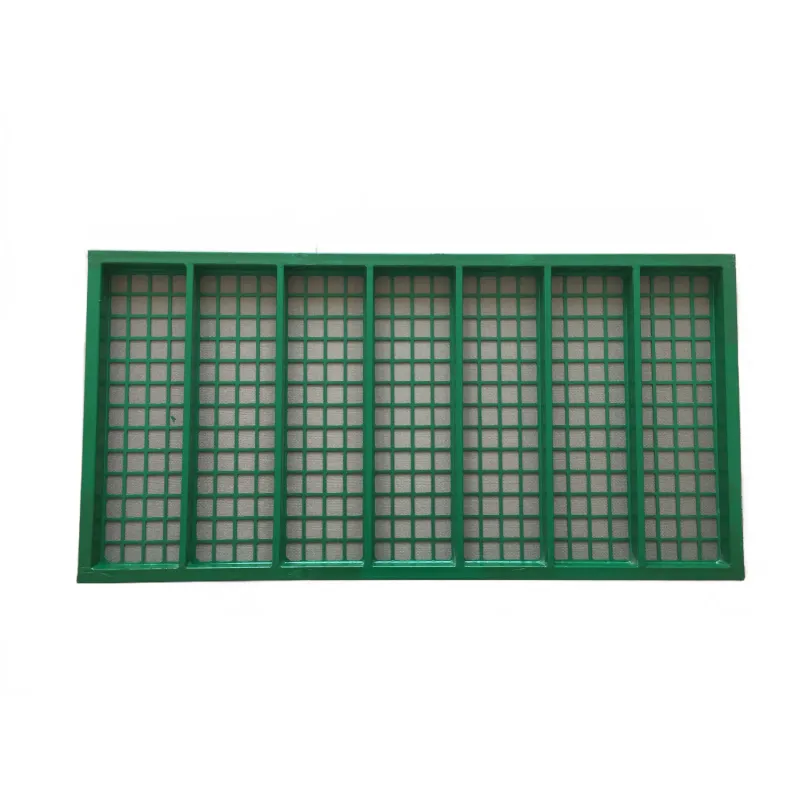

Moreover, heavy duty metal floor grates are highly resistant to corrosion and wear, thanks to protective coatings and finishes. This resistance is vital for installations in environments exposed to chemicals, moisture, and fluctuating temperatures. By choosing galvanized or stainless steel options, businesses can ensure the longevity of their flooring solution, minimizing the need for frequent replacements and repairs.

1. Welded Grating This type is one of the most common and is often available in various standard sizes. Typical dimensions include 24 inches wide by 48 inches long, with bar heights of 1-1/2 inches or 2 inches. The spacing of the bars is essential to ensure adequate drainage while providing sufficient support.

galvanized grating sizes

Stålgrattor är även lätta att installera och underhålla. De kan skräddarsys för att passa specifika mått och behov, vilket gör dem till en flexibel lösning för både industriella och kommersiella applikationer. Genom att erbjuda en säker och stabil yta för fottrafik och fordon minskar de risken för olyckor i arbetsmiljön.

steel mesh floor grating

The manufacturing process also affects the cost. Stainless steel grating is typically produced through methods such as welding or pressing. Hand-welded grating tends to be more expensive due to the labor-intensive process but often results in a superior, more precise product. On the other hand, pressed grating can be more cost-effective but may not offer the same level of quality or customization.

stainless steel grating price