used car dealers suffolk county ny

The manufacturing of galvanized iron wire mesh typically involves several key steps. Initially, high-quality steel or iron wire is sourced, which is then drawn through a series of dies to achieve the desired diameter. After the wire is prepared, it undergoes galvanization, where it is immersed in molten zinc or subjected to a hot-dip galvanization process. This results in a robust protective coat that enhances corrosion resistance.

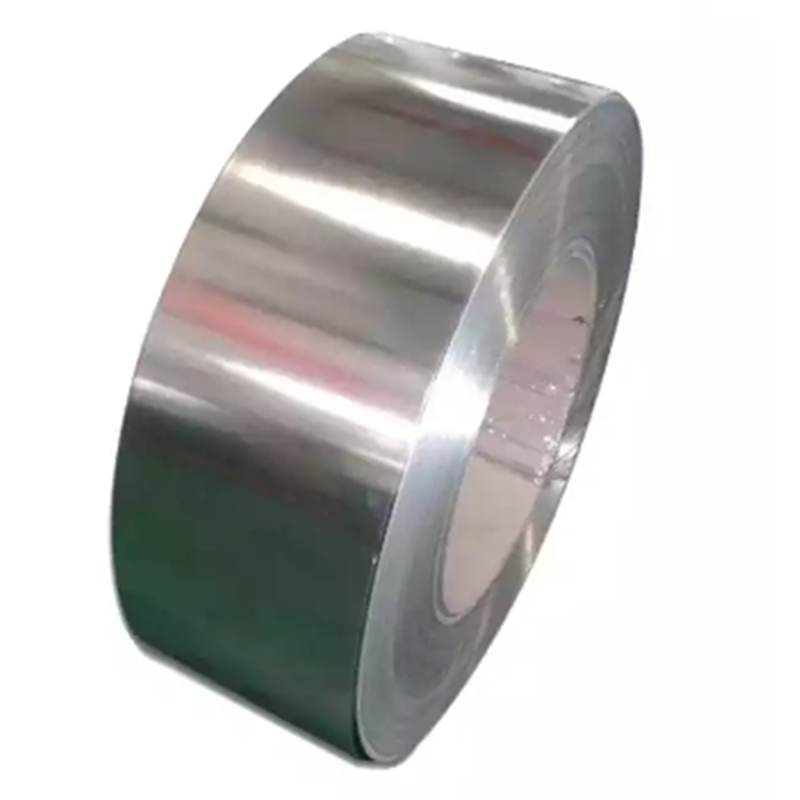

Once the materials are prepared, they undergo a meticulous extrusion process where they are shaped into sheets of various thicknesses and sizes. Cutting-edge machinery allows for precise measurements, ensuring that the slip sheets are custom-fit for different roofing applications. After shaping, the sheets are subjected to rigorous quality control tests, checking for durability, flexibility, and the ability to withstand environmental stresses.

metal roof slip sheet factory

Wire grid panels, also known as wire grid displays , are commonly used in retail environments for showcasing products. These panels are versatile and can be configured in various ways to display items effectively. They are easy to install and reconfigure, making them ideal for dynamic retail spaces.Bricktor is a type of wire reinforcement used in masonry construction to enhance the strength and stability of brickwork. It is embedded in mortar joints to prevent cracking and improve structural integrity.

Brick wall wire mesh also known as brick reinforcing coil or brick wire mesh, is essential for reinforcing masonry structures. It is embedded in the mortar joints of brick walls to enhance tensile strength and prevent cracking. This reinforcement is particularly important in areas prone to seismic activity or where additional structural support is needed.