used cars north carolina

One of the most common applications of galvanized channel iron is in the construction industry. It is widely used in building frameworks, support structures, and scaffolding due to its strength and lightweight properties. Many contractors prefer using galvanized channel iron for structural components, as it provides the necessary support and stability while also reducing the weight of the overall structure. This is particularly advantageous in large commercial projects, where both safety and cost-effectiveness are paramount.

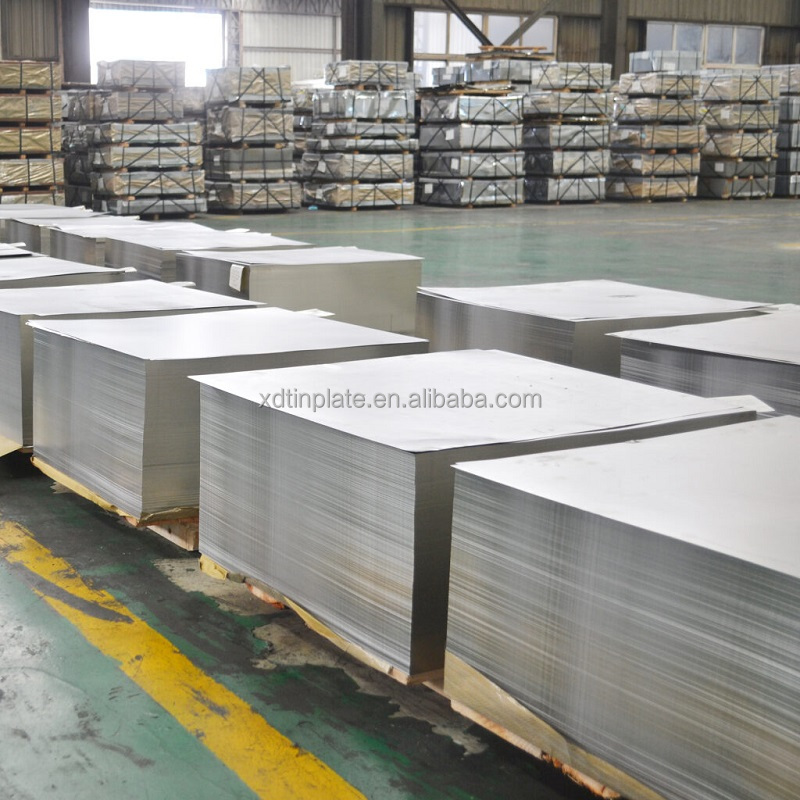

galvanized channel iron factory

In agriculture, galvanized wire netting plays a pivotal role in animal husbandry and crop protection. Farmers utilize this material to create enclosures for livestock, safeguarding animals from predators while allowing for adequate airflow and visibility. Additionally, galvanized wire netting can be used to protect crops from birds and other pests, preventing loss and ensuring a healthy yield. The durable nature of the material means that farmers can rely on it season after season, significantly reducing the need for frequent replacements.

galvanized iron wire netting factory

Moreover, these panels play a pivotal role in sustainable building practices. With an increasing emphasis on eco-friendly materials and energy efficiency, steel’s recyclability makes it a favored choice among builders and architects. Factories are continuously innovating to develop more sustainable practices, with many using recycled steel in their production processes. This not only reduces waste but also lowers the carbon footprint associated with manufacturing.

corrugated sheet steel panels factory

Moreover, galvanized iron water tanks are environmentally friendly. Their long lifespan means that fewer resources are consumed in manufacturing replacements, aligning with global sustainability goals. Manufacturers are also exploring ways to enhance the eco-friendliness of their production processes, such as using recycled materials and reducing energy consumption. This commitment to sustainability not only appeals to environmentally conscious consumers but also sets a standard within the industry.

galvanized iron water tanks manufacturer

The primary purpose of a sheet pan drying rack is to cool baked goods uniformly. After pulling a tray of cookies or a batch of brownies from the oven, placing them on a sheet pan drying rack allows for immediate heat dissipation. Unlike flat surfaces, which may trap heat and moisture, the elevated design of these racks encourages air circulation around the food. This not only prevents sogginess but also helps achieve that coveted crisp texture that many bakers strive for in their creations.

Now, it’s time to hit the grill! Preheat your grill to medium-high heat and place your grill basket on the grates. This specialized basket, with its small holes, allows the heat to circulate while preventing smaller pieces from falling through. Once the basket is hot, add your seasoned vegetables in a single layer for optimal grilling. You may need to cook in batches if you're preparing a large quantity.