used cars in mass

The rise of sheet metal roof factories can be attributed to several factors. Firstly, there is a growing awareness of environmental sustainability. Many homeowners and businesses are striving to reduce their carbon footprint, and metal roofs are an excellent choice due to their recyclability and energy efficiency. Studies show that metal roofs can reflect solar heat, reducing energy consumption for cooling during scorching summers. Thus, factories are not only providing a product but also contributing to sustainable building practices.

sheet metal roof factories

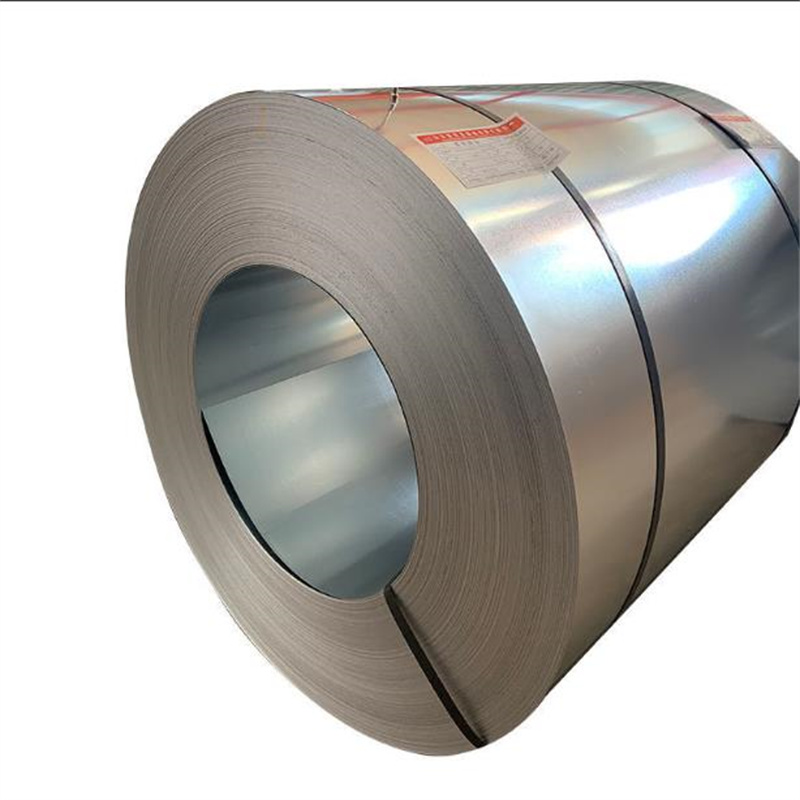

The manufacturing process in custom galvanized iron coil factories generally involves several key steps. First, high-quality steel sheets are sourced, which serve as the base material. These sheets go through continuous hot-dip galvanization, where they are immersed in molten zinc. This process is crucial because it creates a strong metallurgical bond between the steel and the zinc, ensuring superior corrosion resistance.

custom galvanized iron coil factories

3. Epoxy Paints Epoxy coatings provide an exceptionally hardy finish and are often recommended for industrial settings. They offer excellent adhesion, chemical resistance, and durability. However, it’s important to note that epoxy paints generally require higher preparation and curing times, which may not be suitable for every situation.

paint for sheet metal roof supplier

Each material offers different properties, such as corrosion resistance, tensile strength, and temperature tolerance Each material offers different properties, such as corrosion resistance, tensile strength, and temperature tolerance

Each material offers different properties, such as corrosion resistance, tensile strength, and temperature tolerance Each material offers different properties, such as corrosion resistance, tensile strength, and temperature tolerance 8mm hex head bolt. For instance, stainless steel bolts are favored in environments prone to rust or corrosion, while high-strength alloy steel bolts are used in heavy-duty industrial settings.

8mm hex head bolt. For instance, stainless steel bolts are favored in environments prone to rust or corrosion, while high-strength alloy steel bolts are used in heavy-duty industrial settings.