metal roll roofing manufacturer

The rise of large metal boxes factories can be attributed to various technological advancements that have revolutionized the manufacturing process

. Automation and robotics have significantly increased production efficiency, allowing factories to produce large quantities of metal boxes in a relatively short amount of time. This not only reduces labor costs but also minimizes the margin of error, leading to high-quality products that meet industry standards.large metal boxes factories

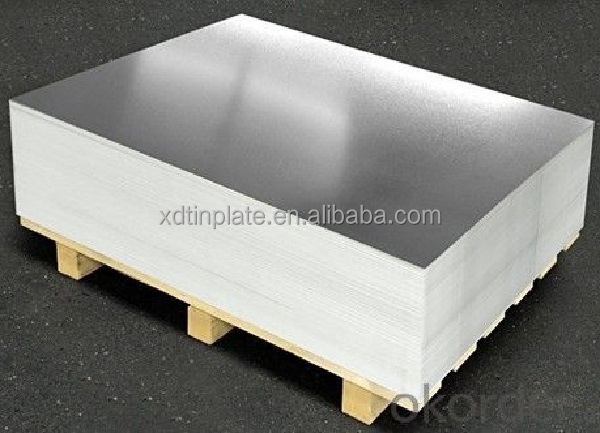

The manufacturing process in custom galvanized iron coil factories generally involves several key steps. First, high-quality steel sheets are sourced, which serve as the base material. These sheets go through continuous hot-dip galvanization, where they are immersed in molten zinc. This process is crucial because it creates a strong metallurgical bond between the steel and the zinc, ensuring superior corrosion resistance.

custom galvanized iron coil factories

Калі вы вырашылі ўсталяваць 8-футавы металічны дах, варта звярнуць увагу на кампаніі з добрай рэпутацыяй. Перш за ўсё, пераканацца ў якасці матэрыялаў, якія выкарыстоўваюцца ў вытворчасці. Нядзіўна, што добрыя вытворцы прапануюць гарантыі на сваю прадукцыю, што сведчыць аб іх упэўненасці ў якасці.

8ft metal roofing manufacturers

Landscape designers often specify these fences due to their ability to be easily integrated into a variety of hardscaping designs, providing both privacy and a refined look to corporate campuses Landscape designers often specify these fences due to their ability to be easily integrated into a variety of hardscaping designs, providing both privacy and a refined look to corporate campuses

Landscape designers often specify these fences due to their ability to be easily integrated into a variety of hardscaping designs, providing both privacy and a refined look to corporate campuses Landscape designers often specify these fences due to their ability to be easily integrated into a variety of hardscaping designs, providing both privacy and a refined look to corporate campuses welded wire fence 48 x 100.

welded wire fence 48 x 100.

wire retaining wall baskets. Unlike traditional stone or concrete retaining walls, which can be labor-intensive and time-consuming to build, wire baskets can be quickly and easily assembled on-site. This can save you both time and money during the construction process.