used cars newark

Factories that produce corrugated metal roofing are equipped with advanced technology and machinery that ensure high-quality output. These facilities typically employ practices that conform to international standards, guaranteeing that the products are not only reliable but also safe for consumers. The production process begins with high-quality raw materials, which are then subjected to cutting, shaping, and coating processes to create the desired roofing panels.

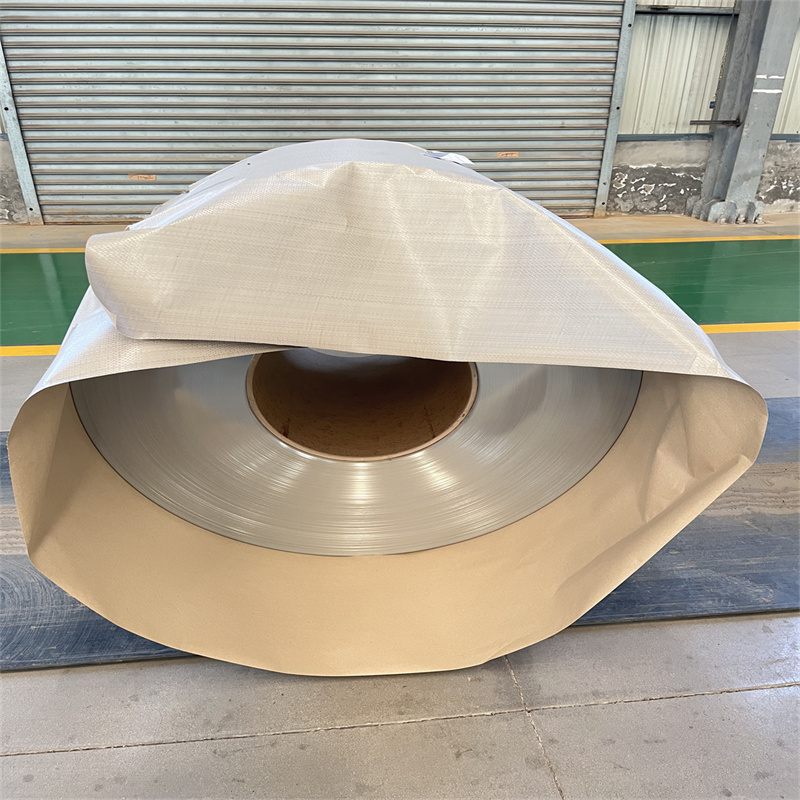

7 8 corrugated metal roofing factory

Quality control is another critical aspect of galvanized iron square pipe factories. The production process involves stringent quality checks to ensure that the finished products meet the necessary specifications. Various tests, including tensile strength and corrosion resistance assessments, are conducted to guarantee reliability and safety. This emphasis on quality not only protects the end-users but also bolsters the reputation of manufacturers in a competitive market.

Corrugated roof sheets come in a variety of materials and profiles, making them suitable for different applications. From agricultural buildings and warehouses to residential homes and commercial spaces, these sheets offer versatile coverage options. Their availability in various lengths, widths, and thicknesses allows builders to choose the right specifications that meet the unique needs of each project.

corrugated roof sheet coverage factories

Roof scope sheet manufacturers specialize in creating these detailed documents. They utilize various technologies, including drones, infrared imaging, and 3D modeling, to gather precise data about a roof's specifications. By employing these advanced methods, manufacturers can ensure that the information on the scope sheets is accurate and comprehensive.

roof scope sheet manufacturers

One of the primary benefits of orange gripper disposable nitrile gloves is their high visibility

. The striking orange color makes them easily noticeable, which is particularly advantageous in high-risk environments such as construction sites, medical facilities, and food service industries. High visibility reduces the likelihood of accidental contact with hazardous materials or contamination, ensuring safety for both the wearer and their surroundings.