Current location:Home > coil metal for roofing factories >

coil metal for roofing factories

2025-08-16 15:21

2025-08-16 14:39

2025-08-16 14:25

2025-08-16 14:06

2025-08-16 14:03

2025-08-16 13:56

2025-08-16 13:49

2025-08-16 13:04

2025-08-16 12:51

2025-08-16 12:44

Latest articles

In addition to quality and delivery, cost is also an important consideration weldmesh suppliers. Manufacturers need to find suppliers who can offer competitive prices without compromising on product quality. This requires suppliers to operate efficiently and keep their costs low, which can be achieved through economies of scale, strategic sourcing, and innovative manufacturing techniques.

weldmesh suppliers. Manufacturers need to find suppliers who can offer competitive prices without compromising on product quality. This requires suppliers to operate efficiently and keep their costs low, which can be achieved through economies of scale, strategic sourcing, and innovative manufacturing techniques.

weldmesh suppliers. Manufacturers need to find suppliers who can offer competitive prices without compromising on product quality. This requires suppliers to operate efficiently and keep their costs low, which can be achieved through economies of scale, strategic sourcing, and innovative manufacturing techniques.

weldmesh suppliers. Manufacturers need to find suppliers who can offer competitive prices without compromising on product quality. This requires suppliers to operate efficiently and keep their costs low, which can be achieved through economies of scale, strategic sourcing, and innovative manufacturing techniques.This is where Spring comes into play. The Spring framework is renowned for its dependency injection (DI) feature, which simplifies the process of managing dependencies between different parts of an application. By using Spring, developers can easily integrate Swing Extension components into their applications without worrying about manual instantiation and configuration. The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications

The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications swing extension spring.

swing extension spring.

The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications

The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications The framework takes care of wiring up the components, allowing developers to focus on the core functionality of their applications swing extension spring.

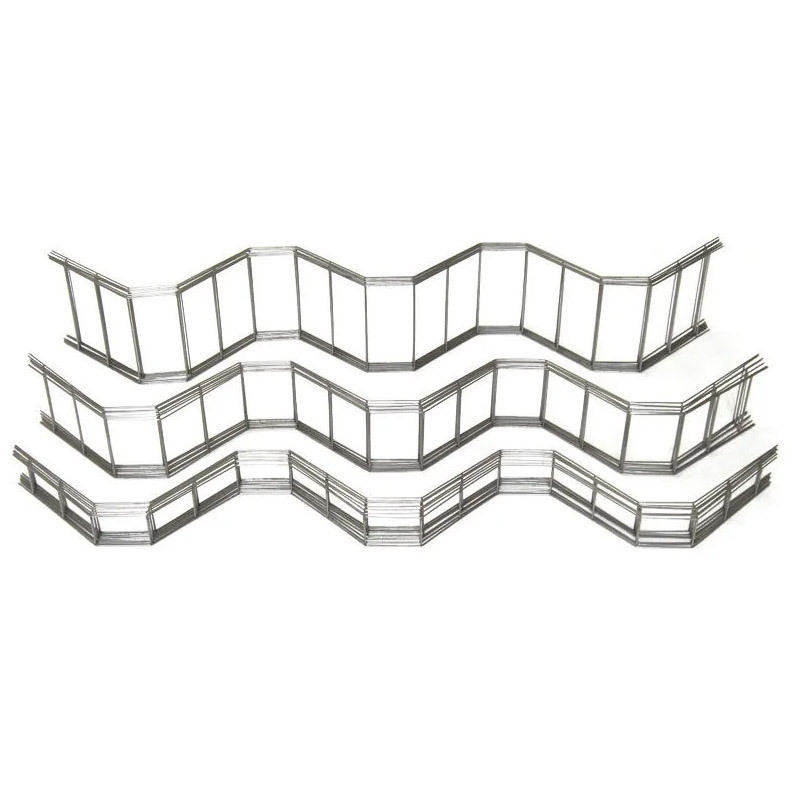

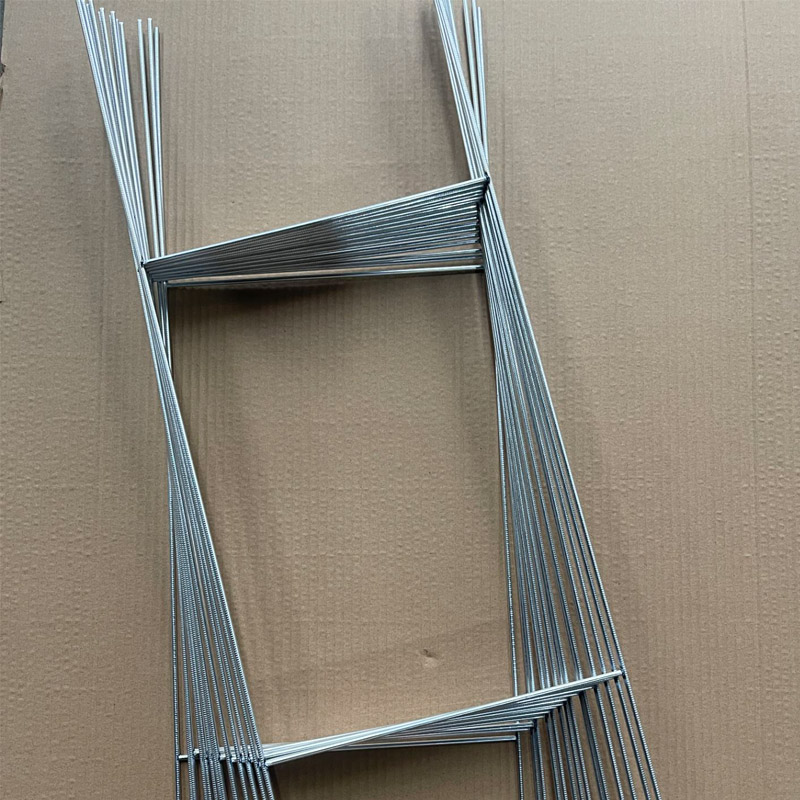

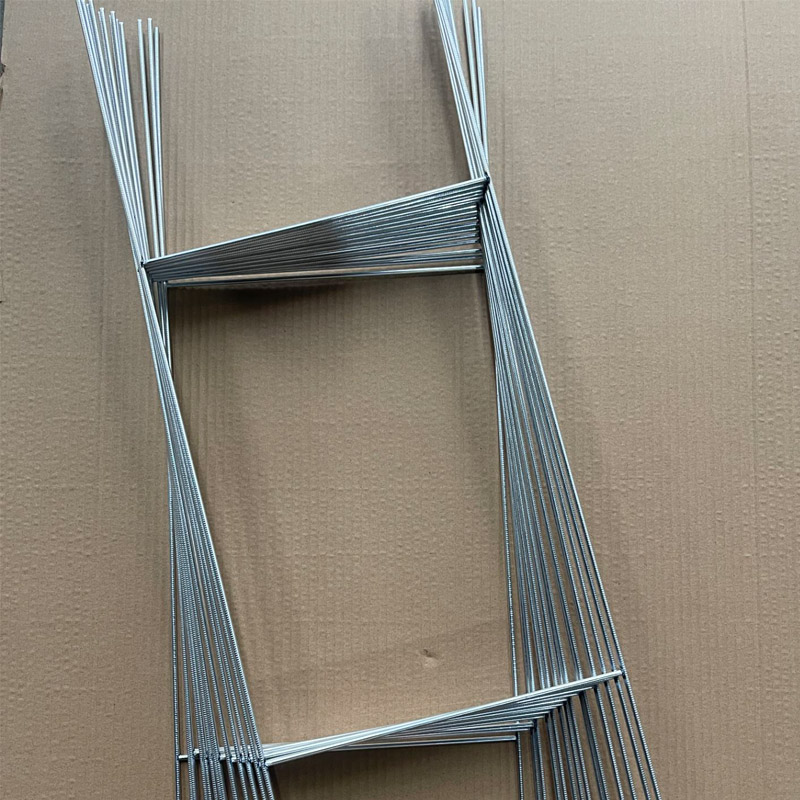

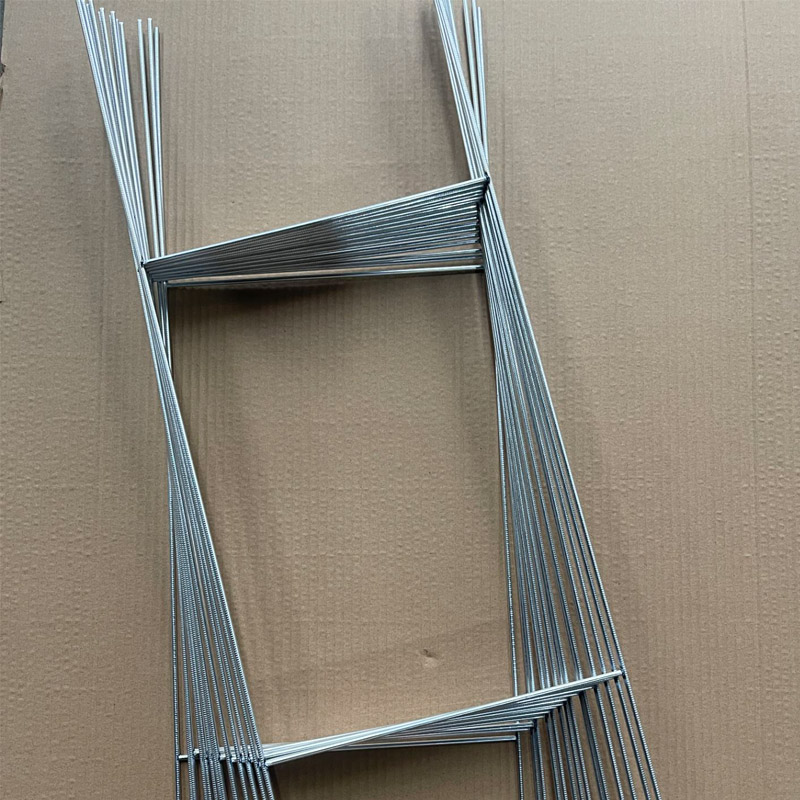

swing extension spring.The installation process of cavity wall brick ties is meticulous. They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load

They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.

cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.

They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load

They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load They are placed at regular intervals, typically every 450-600mm horizontally and 300-600mm vertically, to ensure uniform distribution of load cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.

cavity wall brick ties. The positioning is critical; too few ties could lead to instability, while too many might compromise the cavity's effectiveness.