hopkinsville used car lots

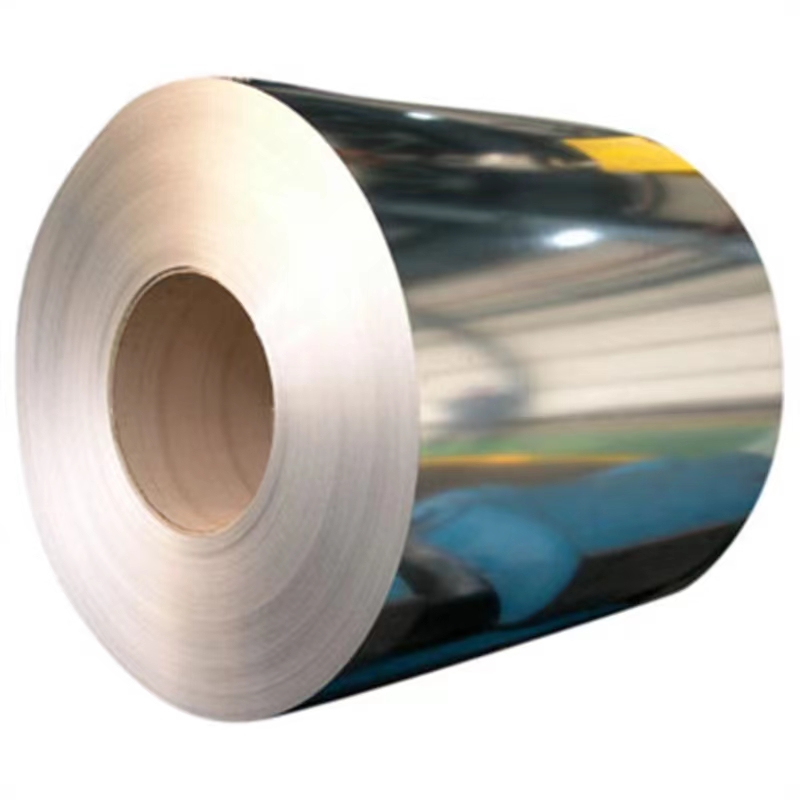

Once the graphics are finalized, manufacturers move to the creation of the tin boxes themselves. The process involves cutting and shaping sheets of steel, which are coated with a layer of tin to prevent rusting and ensure durability. The pieces are then pressed into shape and assembled—usually featuring a hinged lid and a sturdy handle, reminiscent of the lunch boxes popularized in the mid-20th century.

star wars tin lunch box manufacturer

A reputable manufacturer will thoroughly test their galvanized sheets for various parameters such as thickness, adherence of the zinc coating, and resistance to corrosion. These tests often include salt-spray tests, adhesive tests, and exposure to harsh environmental conditions. The aim is to ensure that the galvanized sheets not only meet but exceed the expectations set by industry standards.

galvanized iron sheet coating manufacturer

With the war effort in full swing, entrepreneurs and established manufacturers recognized the opportunity to invest in tin plate production. Several factors contributed to the growth of this industry during the Civil War. Firstly, the demand for canned goods surged as armies sought efficient means of preserving food for troops in the field. The introduction of canning technology around this time meant that manufacturers needed more tin plates to create containers. This demand proved to be a boon for domestic tin plate manufacturers, who quickly scaled their operations.

civil war tin plate manufacturer

4. Environmental Impact In an era where sustainability is crucial, heat reflective sheets contribute to reducing the urban heat island effect—a phenomenon where urban areas become significantly warmer than their rural surroundings due to human activities. By utilizing reflective roofing materials, cities can mitigate this warming effect, promoting a healthier environment.

buy heat reflective sheet for roof manufacturers

Manufacturers of tin cans play a pivotal role in this industry, as they are responsible for ensuring that these containers meet safety regulations while remaining functional and aesthetically pleasing. The manufacturing process of tin cans involves several steps. First, sheets of steel or aluminum are cut into circles, which are then shaped into the body of the can. These bodies are subsequently coated with a layer of tin to enhance resistance against rusting.

tin cans for food canning manufacturers