2022 mini se hardtop vs 2022 chevrolet bolt ev

Leading manufacturers typically offer a range of galvanizing processes, such as hot-dip galvanizing or electro-galvanizing. Hot-dip galvanizing involves immersing the metal in molten zinc, resulting in a thicker coating that provides superior corrosion resistance. On the other hand, electro-galvanizing applies a thin layer of zinc through an electrochemical process, often resulting in a more polished finish, but may not offer the same level of protection as hot-dip galvanization.

galvanized iron sheet thickness manufacturers

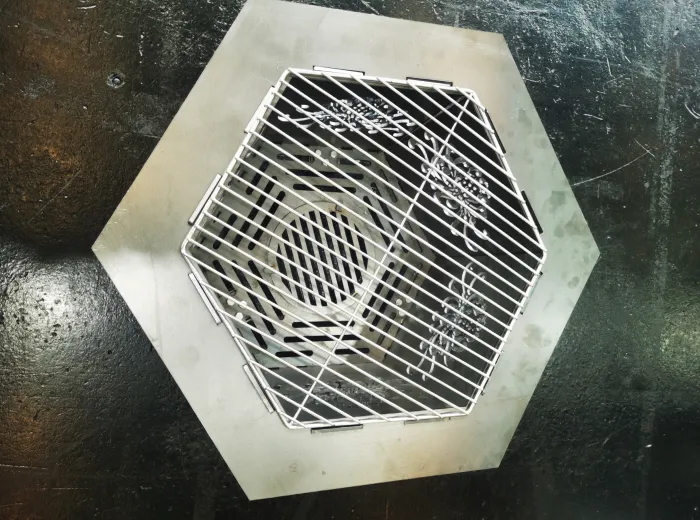

Moreover, cooling racks can also serve various purposes in cooking beyond baking. They can be used for tasks such as roasting vegetables in the oven. By placing vegetables on a cooling rack set within a baking tray, heat can circulate around the food, promoting even cooking and achieving that perfectly roasted flavor. The same technique can be applied when preparing meats; placing chicken or pork chops on a cooling rack allows fat to drain off, leading to a healthier meal without sacrificing flavor.

a cooling rack

Moreover, wire cooling racks with handles are not just for cooling baked goods. Their versatile design means they can serve multiple purposes in the kitchen. For instance, they can double as a roasting rack, elevating meats and vegetables while they cook. This elevation allows for better heat circulation and aids in the even cooking of food while also letting fat and drippings drain away. Many cooks find that using a wire rack is a game changer for achieving crispy skin on roasted meats or perfectly baked potatoes.

wire cooling rack with handle

At its core, a sheet pan rack insert is a specialized accessory that allows for optimal use of space in kitchen operations. Traditionally, sheet pan racks serve the purpose of holding multiple sheet pans, often with limited organization. By incorporating inserts, chefs can utilize the rack’s vertical space more effectively, enabling them to arrange pans, trays, or containers with better accessibility and visibility. This organizational improvement not only saves time during peak cooking hours but also reduces the potential for accidents, as items are less likely to topple over.