Current location:Home > cool metal roofing supplier >

cool metal roofing supplier

2025-08-16 17:13

2025-08-16 17:07

2025-08-16 16:49

2025-08-16 16:41

2025-08-16 16:26

- Energy Efficiency Some cap sheets are reflective, helping to reduce heat absorption

. This feature contributes to lower energy costs by keeping the building cooler during hot weather and reducing the need for air conditioning....

2025-08-16 15:59

2025-08-16 15:54

2025-08-16 15:24

2025-08-16 15:01

2025-08-16 14:51

Latest articles

4. Aesthetic Appeal Today’s cool metal roofing options come in a wide variety of colors and styles, allowing homeowners to choose designs that complement their architecture. Advanced manufacturing techniques have made it possible for metal roofs to resemble traditional shingles, tiles, or even slate, offering an attractive and distinctive look.

cool metal roofing manufacturers

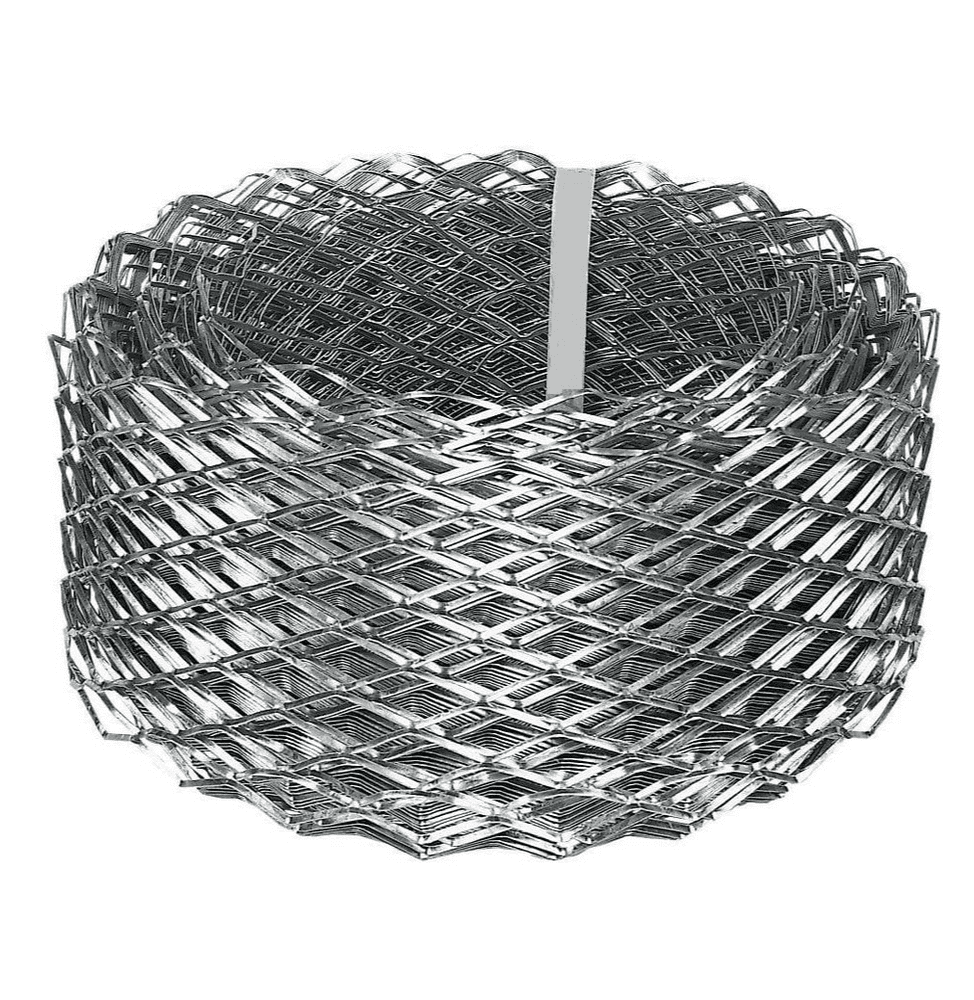

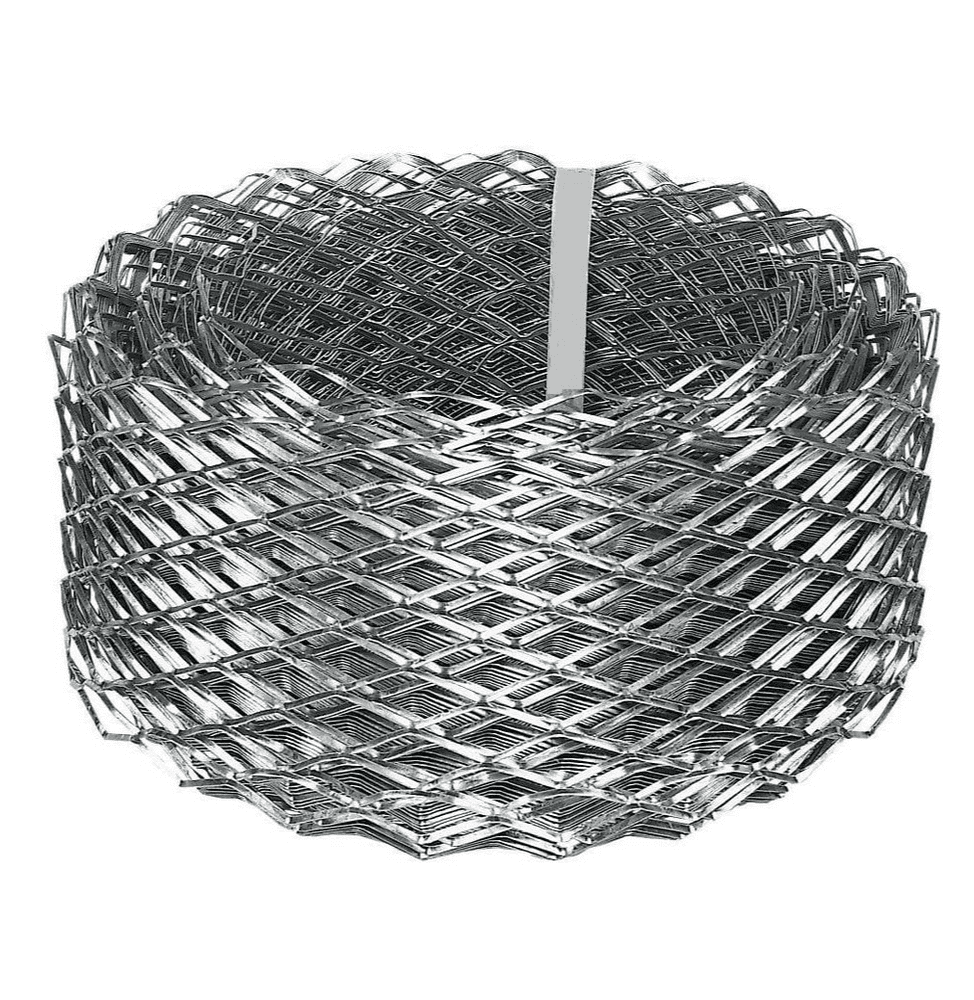

The design and placement of brick ties are critical elements in any construction project. They must be corrosion-resistant to withstand the harsh elements over time. The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes

The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes brick tie detail.

brick tie detail.

The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes

The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes The choice of material, size, and spacing of ties depends on factors such as the width of the cavity, the load the wall will bear, and the local building codes brick tie detail.

brick tie detail.One of the key advantages of using DW-10HS veneer anchors is their versatility. These anchors can be used for a wide range of veneer panel materials, including brick, stone, and precast concrete. This versatility makes DW-10HS anchors a popular choice among architects and builders who want a reliable and efficient anchoring solution for their veneer projects.

The posts are the foundation of the fence and must be installed securely to ensure the fence's stability field fence installation. The distance between posts should be determined based on the type of fence material and the size of your livestock. For example, a barbed wire fence typically requires posts every 8-10 feet, while an electric fence may require posts every 50-100 feet. Once the posts are in place, they should be set in concrete to ensure they remain upright and in place.

field fence installation. The distance between posts should be determined based on the type of fence material and the size of your livestock. For example, a barbed wire fence typically requires posts every 8-10 feet, while an electric fence may require posts every 50-100 feet. Once the posts are in place, they should be set in concrete to ensure they remain upright and in place.

field fence installation. The distance between posts should be determined based on the type of fence material and the size of your livestock. For example, a barbed wire fence typically requires posts every 8-10 feet, while an electric fence may require posts every 50-100 feet. Once the posts are in place, they should be set in concrete to ensure they remain upright and in place.

field fence installation. The distance between posts should be determined based on the type of fence material and the size of your livestock. For example, a barbed wire fence typically requires posts every 8-10 feet, while an electric fence may require posts every 50-100 feet. Once the posts are in place, they should be set in concrete to ensure they remain upright and in place.