metal roofing coil supplier

Moreover, many factories prioritize sustainability in their production processes. By using recycled materials and implementing energy-efficient practices, these modern facilities contribute to a greener environment. This commitment to sustainability appeals to a growing segment of consumers who are conscious of their ecological footprint. As legislation surrounding environmental practices becomes stricter, factories that adopt sustainable methods position themselves favorably in the market.

galvanized iron square pipe factories

1. Surface Preparation The success of soldering hinges on proper surface preparation. Before soldering, it is essential to remove any oils, dirt, or oxidation from the surface. For galvanized iron, this often means using a wire brush or sandpaper to clean the area. It's also critical to remove the zinc coating at the joints to promote better adhesion.

soldering galvanized iron manufacturer

A reputable manufacturer will thoroughly test their galvanized sheets for various parameters such as thickness, adherence of the zinc coating, and resistance to corrosion. These tests often include salt-spray tests, adhesive tests, and exposure to harsh environmental conditions. The aim is to ensure that the galvanized sheets not only meet but exceed the expectations set by industry standards.

galvanized iron sheet coating manufacturer

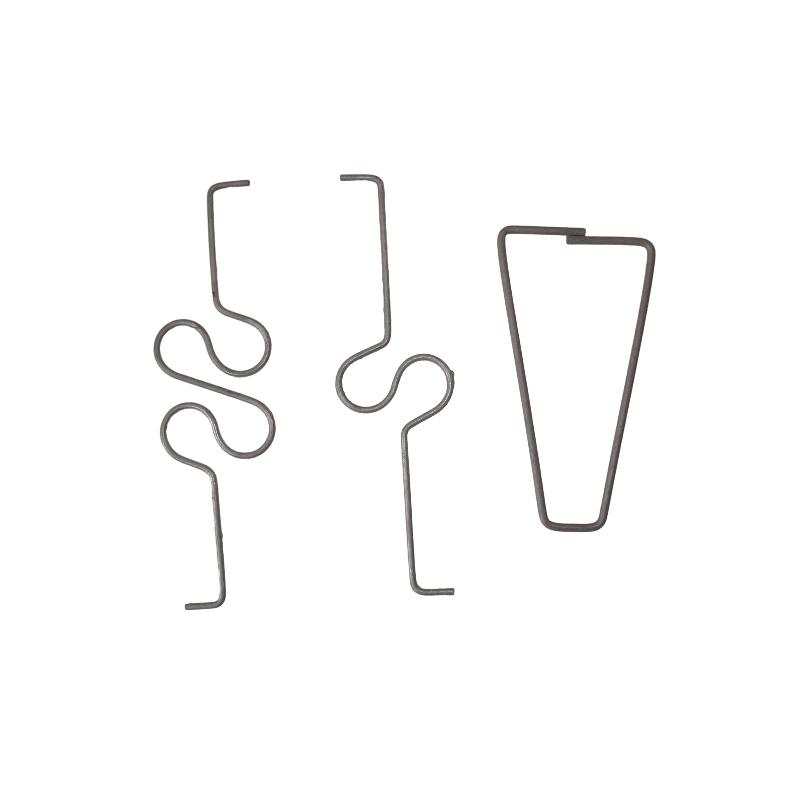

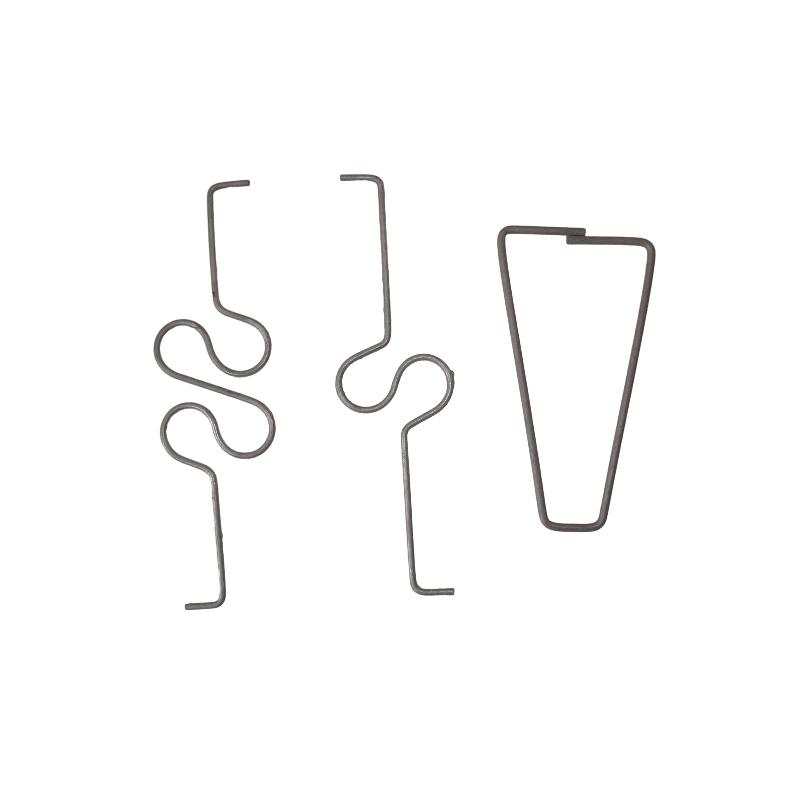

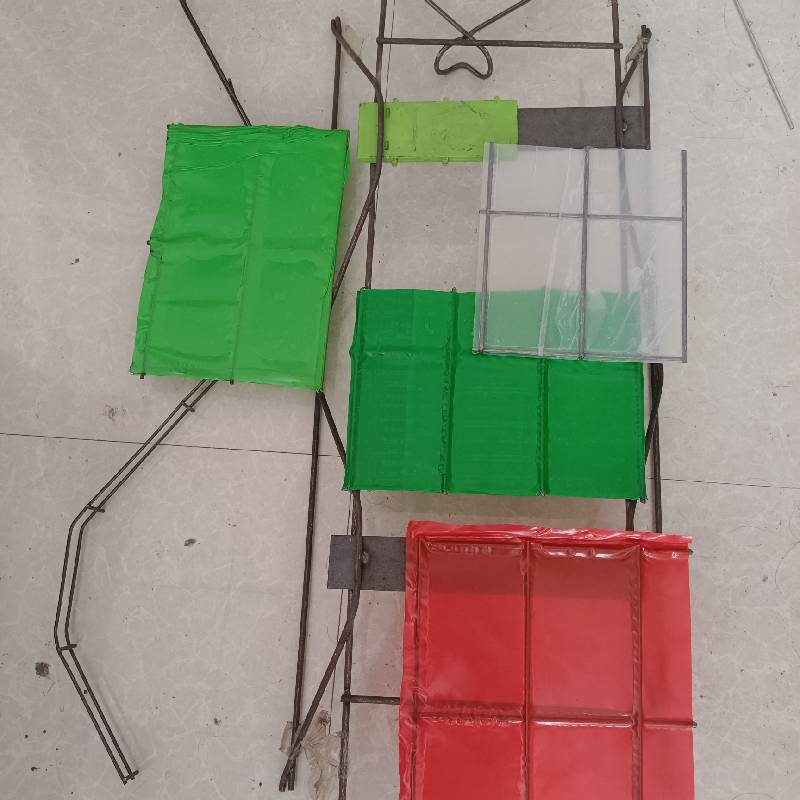

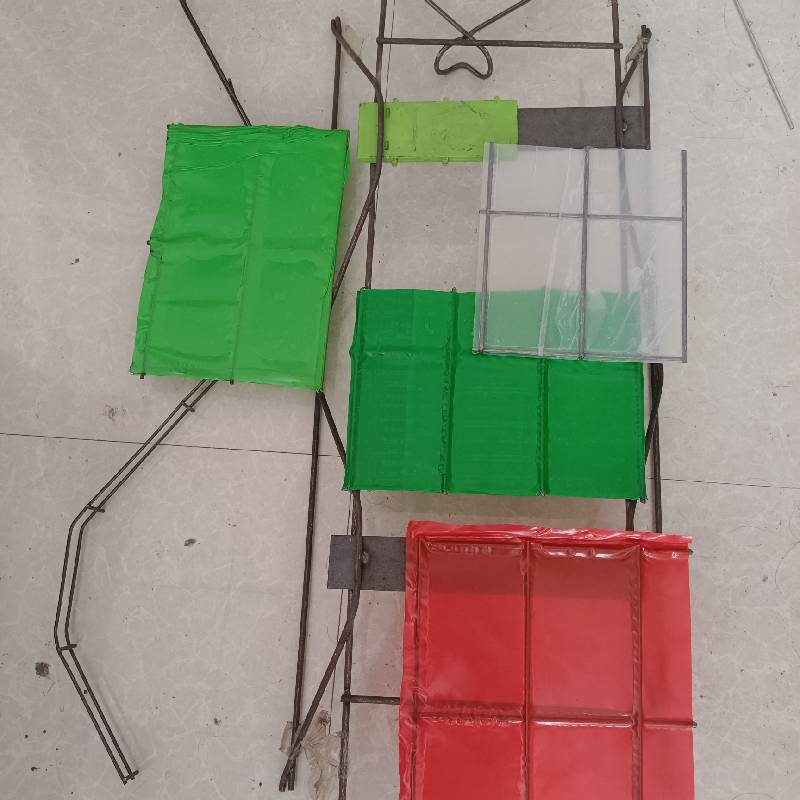

The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic

The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic The sleek and minimalistic design of these boards can complement a variety of decor styles, from modern and industrial to bohemian and eclectic metal grid display board. They are a great way to display artwork, photographs, and other decorative items in a contemporary and stylish way.

metal grid display board. They are a great way to display artwork, photographs, and other decorative items in a contemporary and stylish way. It can be used to create unique wall art, candle holders, or even as a frame for mirrors and pictures It can be used to create unique wall art, candle holders, or even as a frame for mirrors and pictures

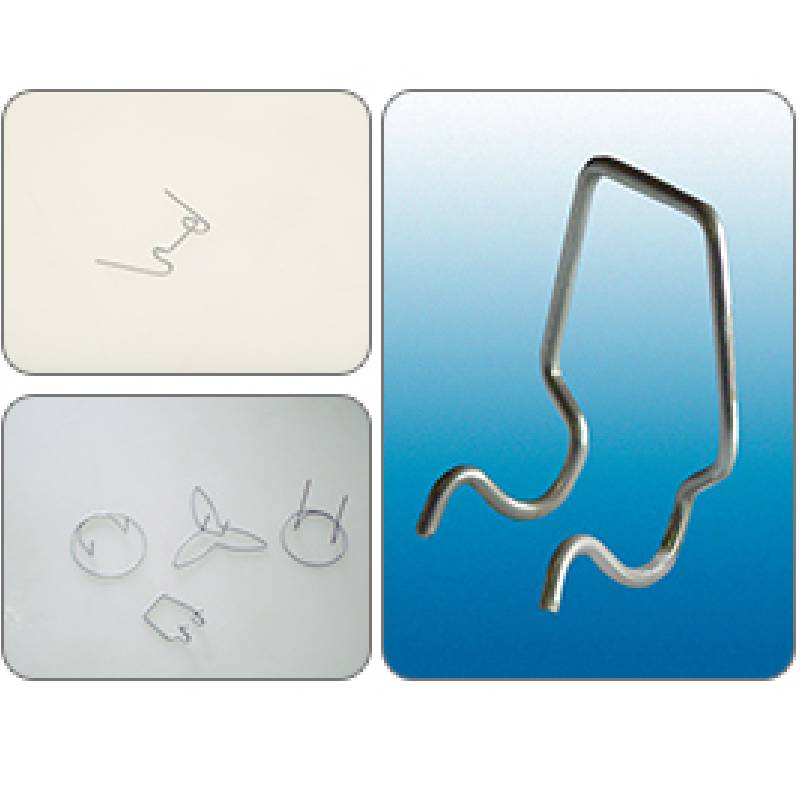

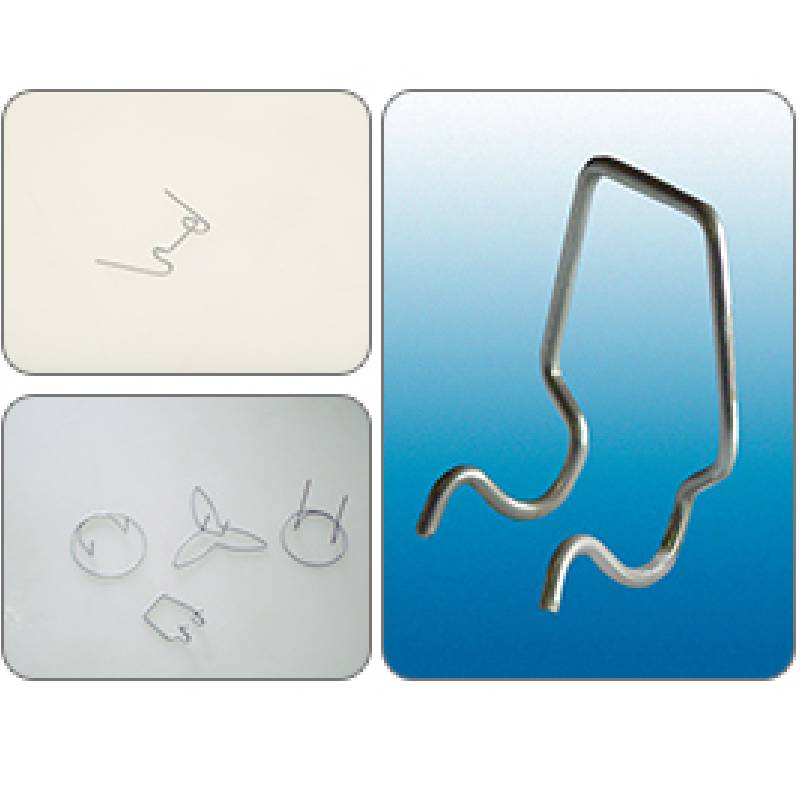

It can be used to create unique wall art, candle holders, or even as a frame for mirrors and pictures It can be used to create unique wall art, candle holders, or even as a frame for mirrors and pictures rose gold craft wire. The wire's strength enables it to hold its shape, ensuring durability in functional pieces.

rose gold craft wire. The wire's strength enables it to hold its shape, ensuring durability in functional pieces.

cheap tomato cages for sale.

Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations

Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations Its resistance to rust makes it an ideal choice for farmers who need reliable and long-lasting solutions in their operations 9 galvanized wire. Furthermore, it can be used to create stable structures for crop support, ensuring the health and productivity of plants.

9 galvanized wire. Furthermore, it can be used to create stable structures for crop support, ensuring the health and productivity of plants.

handcraft wire jewelry.