ally bank used car loan rates

अल्बुकर्क के टिन कैन निर्माता पर्यावरण के प्रति सजग हैं। वे स्थायी निर्माण प्रक्रियाओं को अपनाने पर जोर देते हैं, जैसे कि पुनर्नवीनीकरण सामग्री का उपयोग। इसके माध्यम से, वे अपनी कार्बन फुटप्रिंट को कम करने में मदद कर रहे हैं और स्थानीय समुदाय में स्वच्छता और स्वास्थ्य के प्रति जागरूकता बढ़ा रहे हैं।

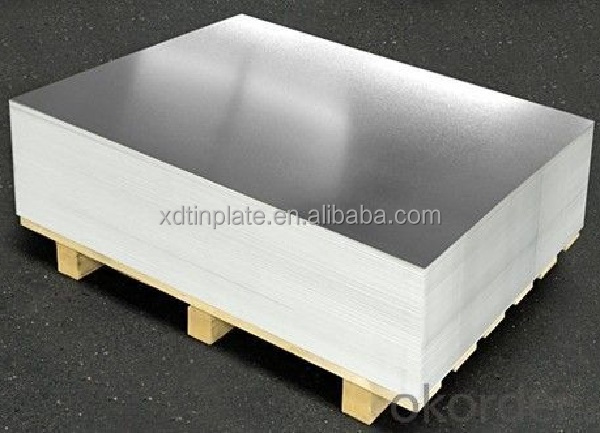

tin can albuquerque manufacturer

1. Hot-Dip Galvanizing This method entails cleaning the iron or steel surface and then immersing it in a bath of molten zinc at approximately 450 degrees Celsius. Once coated, the metal is removed and allowed to cool, resulting in a thick, adherent zinc layer that forms various compounds with the underlying iron. This method is known for producing robust coatings suitable for heavy-duty applications.

galvanized iron meaning manufacturer

The precision of automatic paint spraying systems is unparalleled

. Unlike manual spraying, these machines guarantee a uniform coat, reducing overspray and minimizing paint wastage. This feature is particularly advantageous in large-scale manufacturing setups where precision and cost-efficiency are paramount. For instance, in the automotive industry, where even the slightest inconsistency can lead to a degraded product perception, automated systems have become essential. My experiences have been corroborated by countless industry leaders who have reported up to 30% increases in efficiency post-adoption.