infiniti used cars g37

Once produced, the foam sheets are cut to size and prepared for distribution. Quality control is integral to the process, which includes testing for insulation effectiveness, durability, and resistance to various environmental factors. It is essential for manufacturers to comply with industry standards and regulations concerning safety and environmental impact, which adds an additional layer of integrity to the production process.

foam roof sheet factories

The factory process behind metal lunch boxes often involved a series of intricate steps. First, the raw materials were sourced and cut into the appropriate sizes. Next, the metal sheets underwent printing, where vibrant colors were applied to create eye-catching designs. The pieces were then shaped, bent, and fused together, creating a sturdy construction that could withstand the rigors of daily use. Finally, a protective coating was applied to guard against rust, ensuring these lunch boxes would endure for years.

metal lunch boxes vintage factory

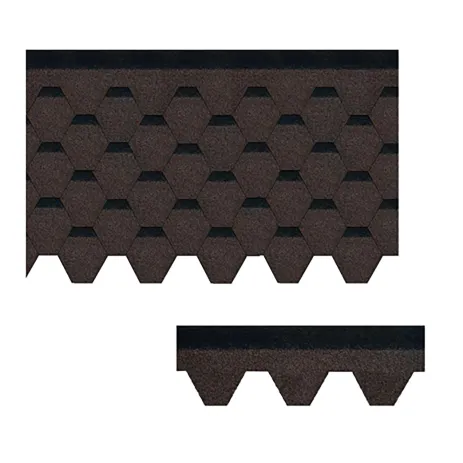

The production of roof tiles during the Roman Empire was a highly developed craft. Romans established factories, often located near significant building projects, to mass-produce these tiles. Artisans developed various techniques to create tiles with different patterns and glazes, allowing for personalization in construction. The color and finish of these tiles could vary, giving homeowners the ability to choose styles that complemented their tastes or the overall design of their estates. This ability to customize was particularly evident in luxurious villas, where different shades of tiles might adorn roofs, enhancing their aesthetic appeal.

roof tiles roman