used cars cda id

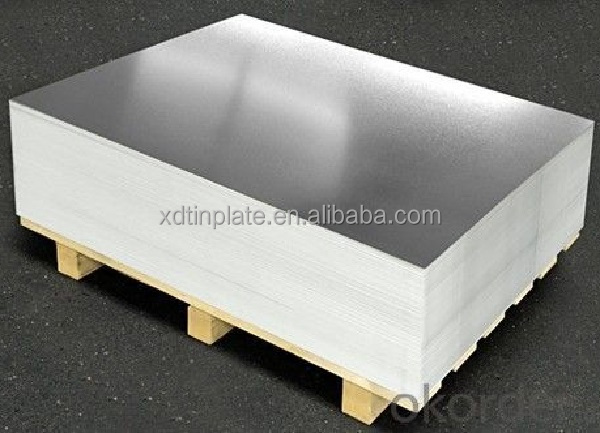

2. Manufacturing Processes The production of corrugated stainless steel sheets involves precise manufacturing techniques. Factors like the complexity of the corrugation, thickness of the steel, and customization options (such as coatings and finishes) can significantly impact the final price. Advanced manufacturing methods that ensure higher quality and durability often demand greater investment, which can elevate costs.

Furthermore, the manufacturing technology in asphalt sheet roof factories has advanced significantly over the years. Automated systems enable higher precision in measurements and designs, resulting in consistent quality across products. Additionally, these factories often implement rigorous quality control measures to ensure that every sheet produced meets specific standards, thereby reducing waste and enhancing overall sustainability.

asphalt sheet roof factories

Moreover, metal roofing is an environmentally friendly option. Many metal roof manufacturers utilize recycled materials in their products, and the roofs themselves are 100% recyclable at the end of their lifespan. This focus on sustainability is becoming increasingly important as consumers and businesses seek to minimize their environmental impact. Additionally, metal roofs reflect heat, which can lead to lower energy costs in warmer climates, further enhancing their appeal among environmentally conscious buyers.

3 ft by 12 ft metal roofing factories

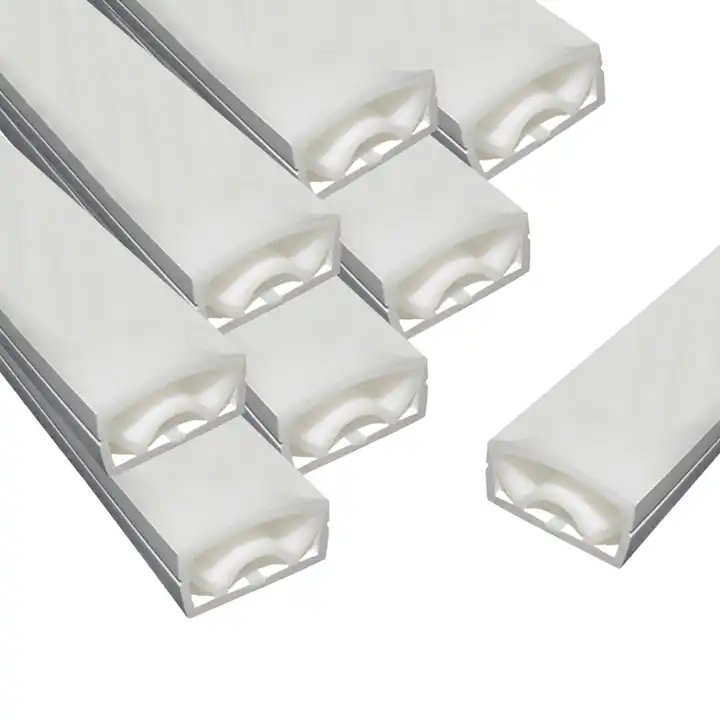

In terms of efficiency, silica gel LED strips exhibit impressive energy-saving capabilities. LEDs consume significantly less power compared to incandescent and fluorescent lights, resulting in lower electricity bills and a reduced carbon footprint. Furthermore, silica gel LED strips are known for their long lifespan, often lasting up to 50,000 hours, which minimizes the need for frequent replacements. This longevity contributes to sustainability, aligning perfectly with global initiatives to promote energy-efficient and eco-friendly products.

china silica gel led strip