what are good cars to buy used

When it comes to manufacturers of galvanized iron sheets, various factors can influence the quality and reliability of their products. Established manufacturers often adopt stringent quality control measures to ensure that their products meet industry standards. They employ advanced coating technology and utilize high-quality raw materials to produce sheets that can withstand harsh environmental conditions.

Using high-quality soldering equipment is equally important. A soldering iron with appropriate heat settings is crucial, as overheating can damage the zinc coating and lead to unsatisfactory results. Flux, which is used to promote the flow of solder and prevent oxidation, must also be selected carefully; specific types, like rosin-based fluxes, are often more effective on galvanized surfaces.

soldering galvanized iron supplier

3. Manufacturing Processes Different manufacturers adopt various production techniques that can impact the final price of acrylic roof sheets. Automated processes can lead to lower labor costs and higher efficiency, potentially reducing the price for consumers. However, manufacturers that prioritize hand-crafted quality or special finishes may charge a premium.

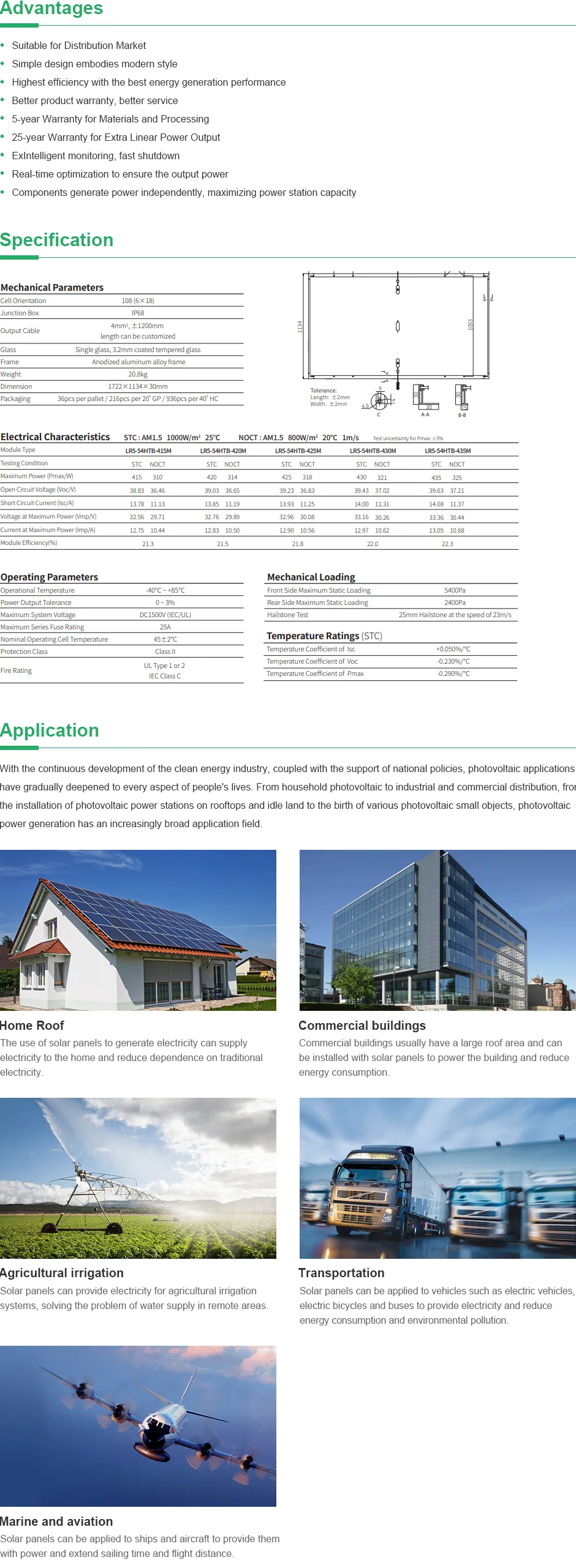

Aesthetics and integration into architectural designs have also seen significant improvements. The development of building-integrated photovoltaics (BIPV) allows solar cells to be seamlessly incorporated into building materials. From solar roof tiles to solar windows, BIPV technology not only generates electricity but also maintains the visual appeal of buildings. This innovation encourages more property owners to adopt solar technology, as it eliminates the need for bulky external installations that can detract from architectural beauty.

new solar panels