volkswagen passat used car

Post galvanization, the sheets are cooled and trimmed to the desired dimensions. Quality control is paramount throughout the production process; factories conduct rigorous tests to ensure that the galvanized sheets meet industry standards in terms of thickness, coating weight, and finish.

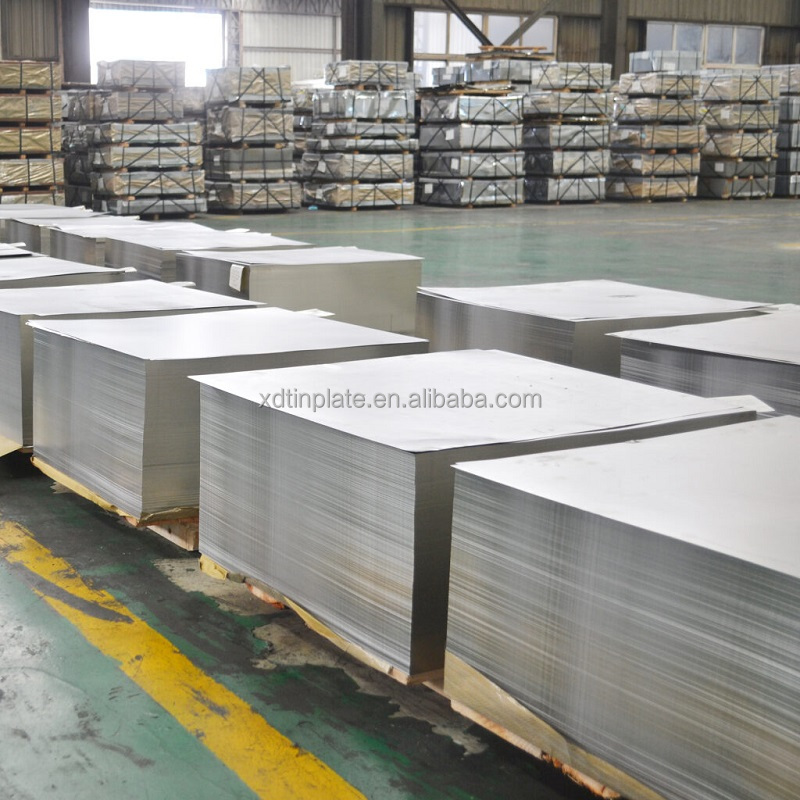

galvanized iron steel sheet factories

4. Installation Costs Beyond the cost of the cooling sheets themselves, installation expenses should also be considered. Some materials can be applied by savvy DIY homeowners, while others may require professional installation. Hiring a professional can add to the overall cost but may ensure proper installation and long-term performance.

cooling sheet for roof price supplier

2. Manufacturing Processes The method of production plays a critical role in pricing. Factory-produced metal sheets often benefit from economies of scale, reducing the cost per unit. However, advanced manufacturing techniques, such as precision cutting and surface treatments, can add to the production costs. The level of automation and technology used in factories also impacts pricing, as more advanced production lines may require higher initial investments.

metal sheet for roof price factory

2. Spherical Vessels Spherical pressure vessels provide a unique solution by minimizing stress concentrations due to their geometric shape. This design is particularly beneficial for storing gases at very high pressures. Although they occupy more space, their strength and efficiency in handling pressure make them suitable for specific applications.

وعاء ضغط الغاز

![<p>\[ f = \frac{64}{Re} \]</p><br>](https://www.xdtinplate.com/https://www.xdtinplate.com/images/3_202401201040239665.webp)