can you use rubbing alcohol on car paint

The factory process behind metal lunch boxes often involved a series of intricate steps. First, the raw materials were sourced and cut into the appropriate sizes. Next, the metal sheets underwent printing, where vibrant colors were applied to create eye-catching designs. The pieces were then shaped, bent, and fused together, creating a sturdy construction that could withstand the rigors of daily use. Finally, a protective coating was applied to guard against rust, ensuring these lunch boxes would endure for years.

metal lunch boxes vintage factory

2. Size and Coverage The price of cooling sheets is also influenced by the size required for your roofing project. Larger roofs will necessitate more material, thus increasing the overall cost. When budgeting for cooling sheets, it is essential to measure your roof accurately and consider any additional materials needed for installation.

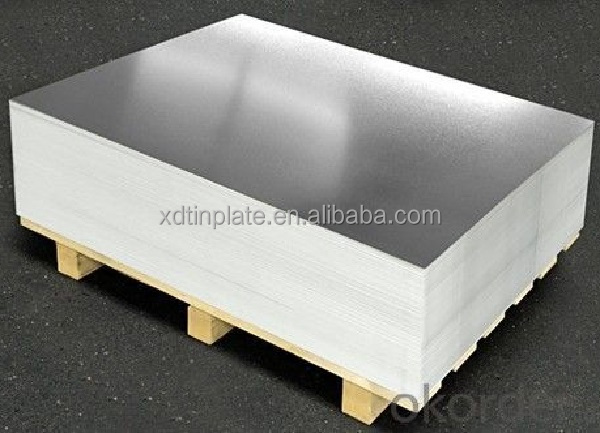

Moreover, manufacturers are constantly innovating to enhance the properties of tin plate sheet metal. Advances in coating techniques, for instance, have led to the development of tin plates with improved corrosion resistance and mechanical strength. These innovations are driven by the need for materials that perform well under various environmental conditions while also being cost-effective for manufacturers and consumers.

tin plate sheet metal manufacturers