Th11 . 20, 2024 08:24 Back to list

tin oil can gif factory

The Art of Tin Oil Can Manufacturing

In the realm of industrial design and manufacturing, few items are as iconic and functional as the tin oil can. These seemingly simple containers play a crucial role in the transportation and dispersion of oils and liquids, serving both utilitarian and aesthetic purposes. The process of creating these cans is a fascinating journey that encapsulates craftsmanship, innovation, and modern technology.

A Glimpse into the Factory

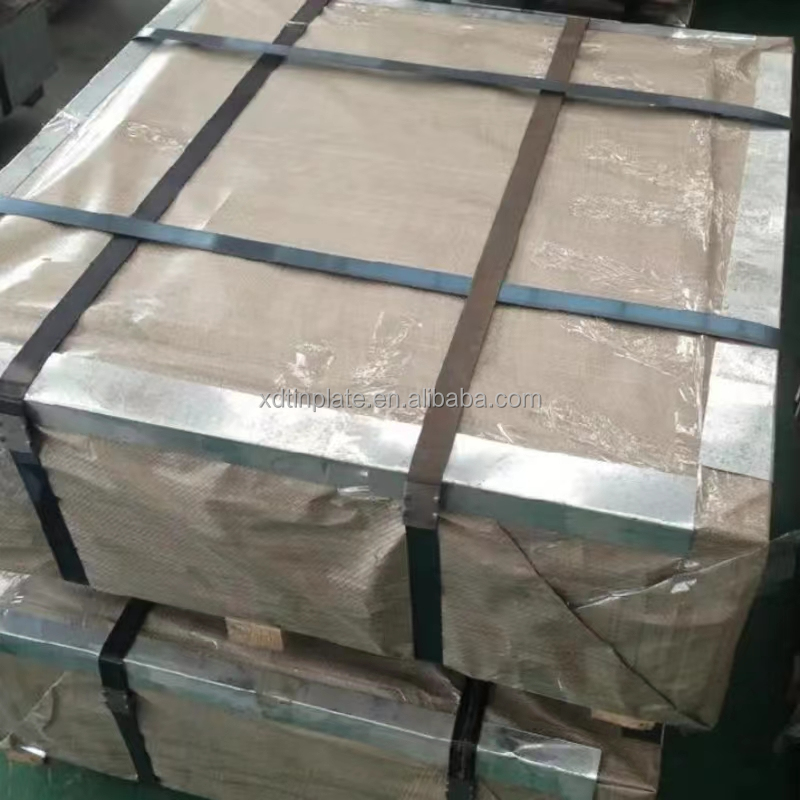

The heart of tin oil can production lies within the factory, where raw materials are transformed into finished products. Upon entering a tin can factory, one is greeted by the rhythmic sounds of machinery, the smell of fresh metal, and the sight of workers diligently focused on their tasks. The production process begins with sheets of tinplate, a combination of steel and a thin layer of tin for corrosion resistance. This selection of materials ensures that the final product is lightweight yet sturdy, perfect for holding various types of oils.

Cutting and Shaping

The first step in the manufacturing process involves cutting the tinplate into specific shapes. High-precision machines are used to ensure that each piece is uniform. Once cut, the tin is subjected to stamping, where it is pressed into the iconic cylindrical form of an oil can. At this stage, manufacturers pay close attention to detail, as even the slightest imperfection could compromise the can's integrity.

Sealing and Finishing

tin oil can gif factory

After the shaping process, the cans must be sealed. This is achieved through a combination of welding and crimping techniques that securely attach the base and the top of the can. Advanced technologies allow for automated processes that enhance both speed and accuracy of production. Following this, the cans undergo a finishing process, which may include painting, printing, and applying labels. The artwork printed on the cans can range from simple logos to complex designs that reflect the brand’s identity and attract consumer attention.

Quality Control

Quality control is an essential aspect of tin oil can manufacturing. Each batch of cans is subjected to rigorous testing to ensure they meet safety standards and can withstand various conditions. There are checks for leaks, structural integrity, and resistance to corrosion. This meticulous approach not only ensures that the final product performs well but also boosts the brand's reputation among consumers.

Sustainability Considerations

In today’s environmentally conscious world, sustainable practices are crucial in manufacturing. Many factories are now incorporating eco-friendly methods, such as reducing waste and utilizing recyclable materials. Additionally, tin cans are endlessly recyclable, making them a sustainable choice for packaging oils and other liquids.

Conclusion

The production of tin oil cans is a blend of art and science, reflecting the evolution of manufacturing techniques over the years. From the initial cutting of tinplate to the final inspection, every step is essential in crafting a product that is both functional and appealing. As technology continues to advance, so too will the methods of production, ensuring that tin oil cans remain a staple in households and industries for generations to come. This timeless piece of design not only fulfills its practical purpose but also embodies the ingenuity and craftsmanship of the manufacturing world.

-

Discover Cheap Cars with GPT-4 Turbo Deals | Save Big Now

NewsAug.04,2025

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025