Th11 . 01, 2024 19:44 Back to list

Soldering Tin Plate Manufacturing Facilities and Their Production Processes

The Importance of Soldering Tin Plate Factories in Modern Electronics

In the ever-evolving landscape of electronics, soldering tin plate factories play a critical role in the manufacturing process. These establishments produce tin plates that are essential for various applications, from circuit boards to connectors in electronic devices. The importance of soldering tin plates cannot be overstated, as they contribute to the reliability and longevity of electronic products.

Solder is a fusible metal alloy used to create a permanent bond between metal workpieces. The most common solder materials are composed of tin and lead, although lead-free alternatives are gaining popularity due to environmental regulations. Tin plates serve as the substrate on which soldering occurs, providing a strong surface that enhances the solder's adhesion to electronic components. The processes involved in soldering tin plate production ensure that the plates meet specific standards for quality and durability.

One of the primary advantages of using soldering tin plates is their excellent conductivity. Tin has superior electrical properties, which makes it ideal for electrical connections. When a soldering tin plate is heated, the solder melts and flows into the joint, creating a strong electrical connection. This is particularly crucial in circuit board manufacturing, where reliable connections can determine the functionality of entire electronic systems.

Moreover, the use of tin plates in soldering applications provides corrosion resistance. Electronics are often exposed to varying environmental conditions, which can lead to corrosion over time. Tin's natural resistance to oxidation helps protect solder joints from deterioration, ensuring that the electronic devices maintain their performance over time. Factories that produce high-quality soldering tin plates focus on refining their materials and processes to enhance this attribute, making their products more valuable to manufacturers.

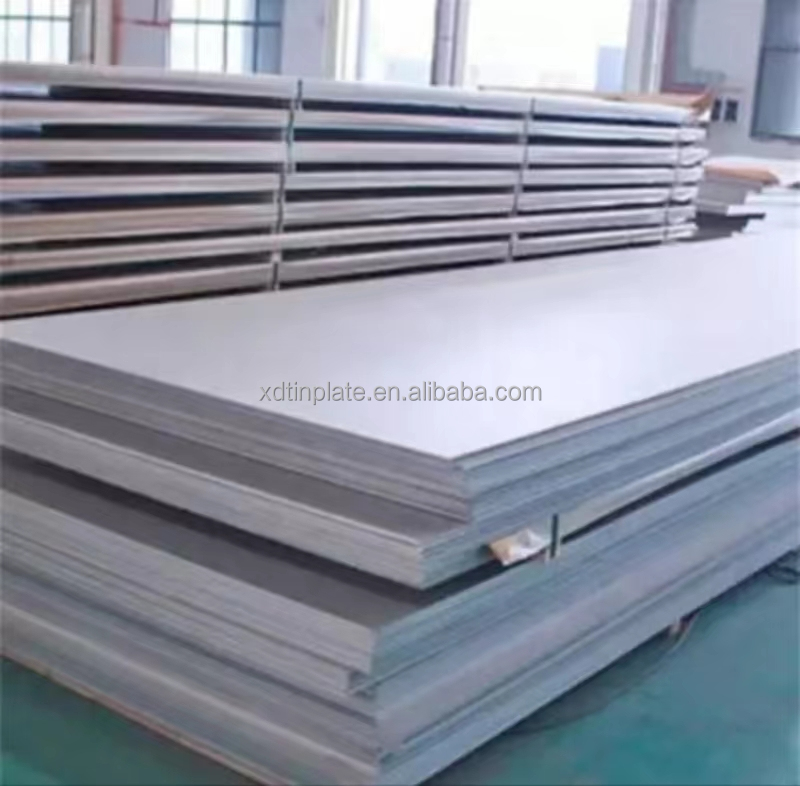

soldering tin plate factories

Soldering tin plate factories are also essential for meeting the increasing demand for electronic devices in our daily lives. With the rise of smartphones, laptops, and other smart devices, the need for reliable soldering solutions has surged. These factories invest in advanced technologies and automation to maintain efficiency and quality in production. As a result, many companies can keep pace with the rapid growth of the consumer electronics market.

In addition to producing tin plates for soldering, these factories also contribute to job creation and economic growth. By employing skilled workers and investing in training programs, they help build a knowledgeable workforce capable of advancing manufacturing technologies. This has multiplier effects on local economies, as high-quality jobs often lead to increased spending and development in surrounding communities.

Furthermore, as environmental concerns grow, soldering tin plate factories are increasingly adopting sustainable practices. Many are transitioning to lead-free solder materials and implementing eco-friendly manufacturing processes. This commitment to sustainability not only helps protect the environment but also meets the expectations of consumers who are becoming more environmentally conscious.

In conclusion, soldering tin plate factories are vital to the electronics industry, providing essential materials that ensure the functionality, reliability, and longevity of electronic devices. As technology advances, these factories will continue to play a crucial role in supporting innovation while adapting to the challenges of sustainability and market demands. Their contributions are fundamental in an increasingly digital world where reliable electronics are indispensable.

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025