Th10 . 11, 2024 15:22 Back to list

Top Metal Sheet Manufacturers for Roofing Solutions and Supply

The Role of Roof Metal Sheet Manufacturers in Modern Construction

In today's construction industry, the demand for durable, sustainable, and aesthetically pleasing building materials is ever-increasing. Among these materials, metal sheets for roofing have gained immense popularity due to their numerous advantages. From their resilience to varying weather conditions to their energy efficiency, metal roofing solutions are favored by builders and homeowners alike. The backbone of this growing market is the roof metal sheet manufacturers who are at the forefront of innovation, quality assurance, and customer service.

Understanding Metal Roofing

Metal roofing typically consists of materials such as steel, aluminum, copper, or zinc. These materials are known for their strength and longevity, making them ideal for various architectural applications. Metal roofing is not only resistant to harsh climatic conditions—such as rain, snow, and hail—but also reflects sunlight, aiding in energy efficiency and reducing cooling costs. Additionally, metal roofs can be made from recycled materials and can themselves be recycled at the end of their life cycle, making them an environmentally friendly option.

The Manufacturing Process

Roof metal sheet manufacturers specialize in producing panels that meet specific standards of quality and performance. The manufacturing process involves several critical steps, starting from the selection of raw materials. High-grade metals are essential, as they ensure durability and longevity.

1. Raw Material Processing The chosen metal stock is cut, coated, and treated to enhance its resistance to corrosion and rust. Coatings like Galvalume or high-quality paints can significantly extend the lifespan of the roofing panels.

2. Forming and Cutting Advanced machinery is employed to roll-form metal sheets into various shapes and profiles, including standing seam, corrugated, or flat panels. Precision is key, as improperly formed sheets can lead to structural issues down the line.

3. Quality Control Roof metal sheet manufacturers invest in rigorous quality control measures to ensure that every panel produced meets industry standards and specifications. This may involve testing for paint adhesion, weather resistance, and structural integrity.

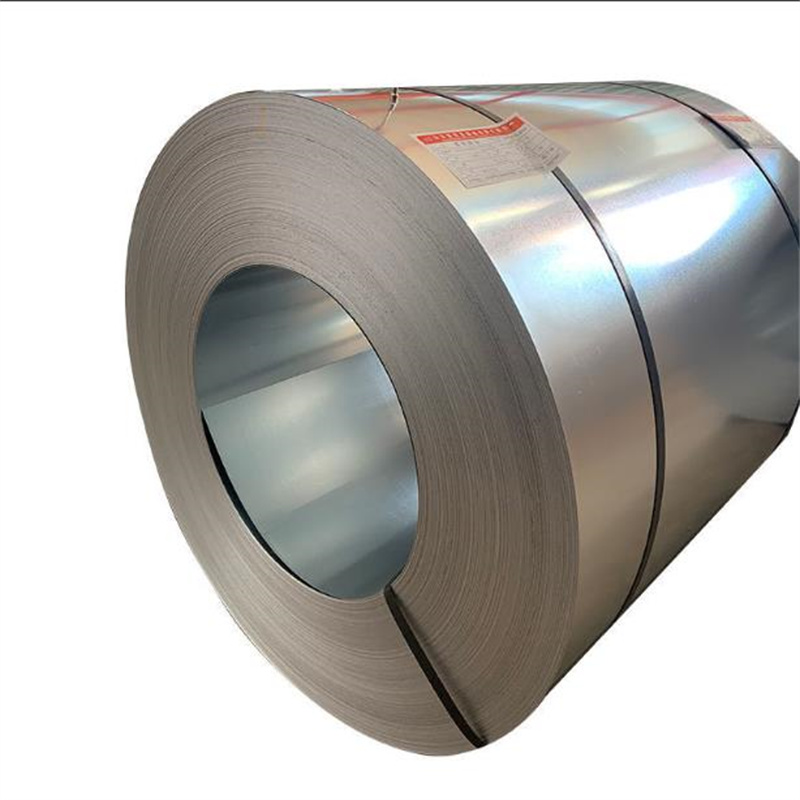

roof metal sheet manufacturers

4. Finishing After the panels are formed, a final inspection is carried out before they are coated, painted, or treated with finishes that enhance their appearance and durability.

Innovation in Metal Roofing

As the construction industry evolves, so do the technologies and practices employed by roof metal sheet manufacturers. Innovations such as advanced coatings, improved insulation properties, and enhanced designs are constantly being researched and developed. Manufacturers are also adopting sustainable practices, such as reducing waste and using renewable energy sources in the production process.

Moreover, the integration of smart technology into roofing solutions is on the rise. Manufacturers are exploring options such as solar reflective coatings, which can actively reduce heat absorption and improve energy efficiency, as well as panels designed to integrate with solar energy systems seamlessly.

The Importance of Choosing the Right Manufacturer

When it comes to purchasing metal roofing solutions, selecting a reputable manufacturer is crucial. Quality assurance, customer service, and warranty offerings are essential factors to consider. A trustworthy manufacturer will not only provide high-quality products but also support customers with installation guidance and after-sales service.

Additionally, many roof metal sheet manufacturers are willing to customize products to meet specific architectural requirements, allowing for unique design elements in construction projects. This adaptability helps builders and architects realize their creative visions while maintaining structural integrity.

Conclusion

In conclusion, roof metal sheet manufacturers play a vital role in the construction industry by providing innovative, durable, and sustainable roofing solutions. As trends in building materials continue to evolve, these manufacturers stand at the forefront of technology and quality, supporting the diverse needs of builders, architects, and homeowners. With their commitment to excellence and sustainability, they are helping to shape the future of modern construction, making it imperative for stakeholders to recognize their significance in the building supply chain.

-

Revolutionary AI for New Energy Vehicles: GPT-4 Turbo Optimization

NewsAug.05,2025

-

Discover Cheap Cars with GPT-4 Turbo Deals | Save Big Now

NewsAug.04,2025

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025