Th10 . 19, 2024 03:19 Back to list

chrome effects tin can factories

The Impact of Chrome Effects in Tin Can Factories

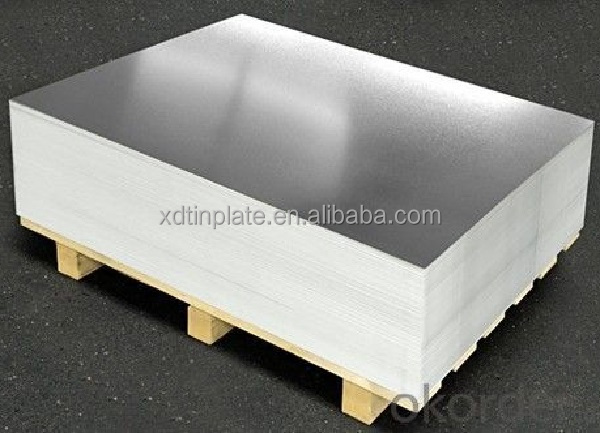

In today's manufacturing landscape, the use of chrome effects has become increasingly relevant, especially in industries like tin can production. The application of chrome finishes to tin cans enhances both aesthetic appeal and practical functionality, making them more attractive to consumers and more competitive in the market. This article explores the significance of chrome effects in tin can factories, examining their advantages, environmental implications, and future trends.

The Impact of Chrome Effects in Tin Can Factories

Beyond aesthetics, chrome effects also offer practical benefits. The chrome plating process enhances the durability and corrosion resistance of tin cans. This is particularly important in industries such as food and beverage, where product safety and longevity are paramount. By applying chrome finishes, manufacturers can help extend the shelf life of canned goods, reducing waste and ensuring that consumers receive products in optimal condition. Additionally, chrome effects contribute to a smoother surface, which can impede the growth of bacteria and facilitate easier cleaning during manufacturing processes.

chrome effects tin can factories

However, the application of chrome effects in tin can factories is not without its environmental implications. The chrome plating process can involve the use of hazardous materials, raising concerns about pollution and workers' safety. Many manufacturers are currently working to address these issues by adopting more sustainable practices and technologies. Innovations such as hexavalent chromium-free processes are being explored to minimize environmental impact while still achieving the desired aesthetic and functional properties. As consumer demand for sustainable products grows, the tin can industry must adapt to meet these expectations.

Looking to the future, the integration of chrome effects in tin can manufacturing is poised for further evolution. Advances in technology are enabling manufacturers to develop more efficient and eco-friendly chrome plating processes. Moreover, the rise of digital printing technologies allows for greater customization, enabling brands to create unique designs that resonate with their target audience. This trend toward personalization aligns with modern consumer preferences, where individuality and brand identity play crucial roles in purchasing decisions.

Additionally, as the industry moves toward a circular economy, the reusability and recyclability of materials will become increasingly important. Chrome finishes can enhance the recyclability of tin cans by ensuring that the materials maintain their integrity throughout the recycling process. Manufacturers will need to focus on developing chrome effects that not only improve aesthetics and functionality but also align with sustainable practices.

In conclusion, chrome effects in tin can factories represent a fusion of beauty and practicality. While they enhance the visual appeal and durability of products, manufacturers must navigate the environmental challenges associated with chrome plating. As the industry embraces innovation and sustainability, the future of chrome effects in tin can production looks promising. By striking a balance between aesthetic enhancement and environmental responsibility, tin can manufacturers can continue to thrive in an ever-evolving market.

-

Cost-Effective Tram: Your New Cute Mini EV Car

NewsAug.06,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025