Th11 . 01, 2024 05:50 Back to list

Factory Production of Galvanized Steel and Cast Iron Pipes for Various Applications

The Evolution of Cast Iron and Galvanized Steel Pipes A Factory Perspective

In the modern age of construction and plumbing, the choice of piping materials plays a critical role in ensuring durability, corrosion resistance, and overall system efficiency. Two materials that have stood the test of time in various applications are cast iron and galvanized steel pipes. This article aims to explore the significance of these materials, particularly from a factory perspective, emphasizing their production processes, advantages, and applications.

Cast iron pipes have been a staple in water and sewage systems for over a century. Known for their strength, these pipes can withstand high pressure and are resistant to fire, making them ideal for underground installations. The production of cast iron pipes involves melting scrap iron and other alloys in a furnace, followed by casting the molten iron into cylindrical molds. After cooling, the pipes are machined to achieve precise dimensions. The durability of cast iron pipes extends their lifespan, often exceeding 50 years with proper maintenance.

On the other hand, galvanized steel pipes are made from steel that has been coated with a layer of zinc to prevent rusting. This process, known as galvanization, significantly enhances the corrosion resistance of the steel. Factories producing galvanized steel pipes often employ techniques such as hot-dip galvanization or electro-galvanization, where the steel pipes are either dipped in molten zinc or coated with zinc through an electrical process. The galvanized pipes are particularly favored in water supply systems for their ability to handle high water pressure and their cost-effectiveness.

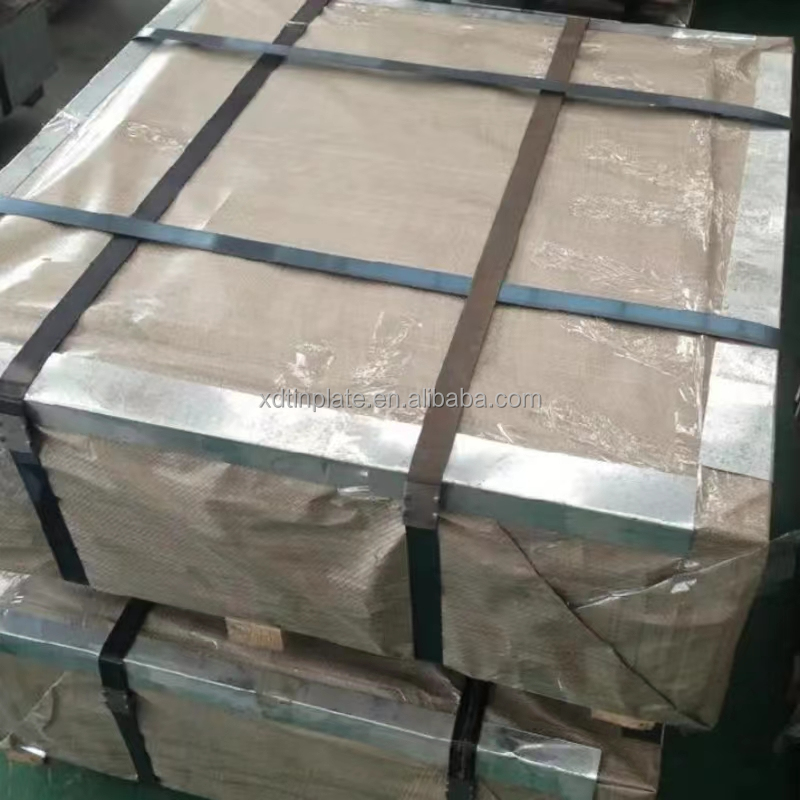

cast iron pipe galvanized steel pipe factory

Both cast iron and galvanized steel pipes have been instrumental in the infrastructure of cities around the world. Cast iron is frequently used in larger applications such as water mains and sewage systems, while galvanized steel is often found in residential plumbing and heating applications. The choice between the two often depends on specific project requirements, including budget, expected lifespan, and environmental conditions.

In recent years, manufacturers have continued to innovate and focus on sustainability. Modern factories are adopting eco-friendly practices, incorporating recycled materials into their production processes, and striving to reduce waste and energy consumption. The demand for high-quality, durable piping solutions has led to advancements in technology, allowing for improved production efficiency and product quality.

In conclusion, the evolution of cast iron and galvanized steel pipes demonstrates the importance of material selection in construction and plumbing. From the robust nature of cast iron pipes to the cost-effective benefits of galvanized steel, both materials have unique advantages that cater to specific needs. As the industry continues to evolve, factories are poised to enhance their production capabilities and meet the growing demands for sustainable and reliable piping solutions, ensuring a strong foundation for future infrastructure development.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025