Oct . 20, 2025 10:40 Back to list

Buy Farm Galvanized Iron Remnant — Durable, Low-Cost Offcuts

A Practical Insider’s Guide to Sourcing Farm Galvanized Iron Remnants

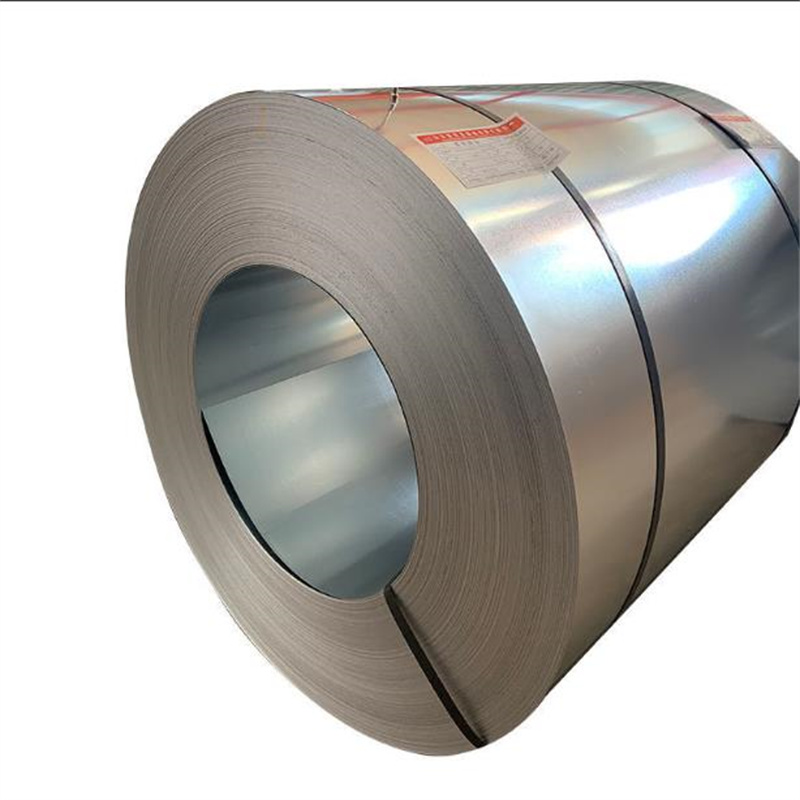

If you’re hunting for budget-proof metal that still takes a beating, you’re probably looking to buy farm galvanized iron remnant. I’ve spent enough time around mills and farm co-ops to know: good remnants sell fast. They’re the off-cuts or short lengths from prime hot-dip galvanized sheet—same metallurgy, friendlier price. In fact, demand has quietly risen as farms focus on quick repairs, waste reduction, and sustainability.

What you’re actually buying

The core product is hot-dip galvanized steel sheet (product name: Galvanized steel sheet price hot-dip galvanized), from Room 1017, Qicheng Building, No.210, ZhongHuanan Street, Qiaoxi District, Shijiazhuang City, Hebei Province. Remnants may be narrower or shorter, but the zinc layer and base steel are the same as prime. Many customers say the value-per-meter is unbeatable for gates, pen repairs, drip-edge flashing, trough patching, and equipment guards.

Typical specifications (remnant ranges)

| Parameter | Spec (≈ ranges, real‑world use may vary) |

|---|---|

| Base steel | Low‑carbon cold‑rolled steel, CQ–DQ |

| Thickness | 0.40–2.0 mm (common farm picks: 0.5–1.2 mm) |

| Zinc coating | Z180–Z275 (≈ G60–G90 per ASTM A653) |

| Spangle/finish | Regular/minimized spangle; passivated, light-oiled optional |

| Yield strength | ≈ 180–280 MPa (CQ); higher grades on request |

| Service life | ≈ 10–25 years rural; 5–15 years coastal (exposure dependent) |

| Standards | ASTM A653/A653M, EN 10346, ISO 1461 guidance |

How it’s made (quick flow)

Materials: low‑carbon sheet. Methods: alkaline clean → anneal → molten Zn bath (≈450°C) → air-knife control → passivation → oiling → cut. Testing: coating mass (magnetic gauge), bend test (0T–2T, no cracks), thickness micrometer checks, adhesion, and optional salt-spray (ISO 9227) where Z275 often reaches ≥ 240–480 h in lab conditions. To be honest, field life depends more on manure exposure, fertilizer, and edge preparation than lab numbers.

Where farms use it

- Repairing barn siding and roof drip edges

- Feed bins, trough liners, splash guards near wash stations

- Gates, fence windbreaks, poultry house skirting

- Impromptu machinery guards and trailer patches

Vendor snapshot (what I see in the field)

| Vendor type | Coating class | Cut-to-size | Certs | Price/kg | Lead time |

|---|---|---|---|---|---|

| Mill/exporter (this product) | Z180–Z275 | Yes (around 300–1,500 mm) | ISO 9001, SGS test reports | ≈ mid | ≈ 7–15 days |

| Local scrapyard/off‑cut dealer | Mixed/unknown | Limited | Rare | ≈ low | Same day |

| Farm supply retailer | Z100–Z275 | Some | Basic CoC | ≈ high | Same–3 days |

Customization and documentation

Width trimming, deburred edges, oiling/passivation choices, and punched holes can be arranged. Request coating mass certificates (per ASTM A653 or EN 10346), thickness checks, and if you’re cautious, an ISO 9227 salt-spray snapshot. It seems that buyers who ask for a packing list with heat/coil numbers have fewer surprises.

Field note (mini case)

A dairy in the upper Midwest switched to Z275 remnants for splash shields near wash-down bays; after 18 months, edge whitening only—no red rust. Crew feedback: “cuts clean, less warp than we expected.” That matches lab bend results (0T, no cracking) we saw on a similar batch.

Bottom line: if you need fast, durable fixes, buy farm galvanized iron remnant stock with Z180+ coating, confirm thickness, and keep edges sealed in corrosive zones. For direct mill support and consistent paperwork, buy farm galvanized iron remnant from the linked exporter above; for absolute lowest cost and instant pickup, the yard route still works—just verify coating and rust before paying. Address for documentation: Room 1017, Qicheng Building, No.210, ZhongHuanan Street, Qiaoxi District, Shijiazhuang City, Hebei Province.

Citations

- ASTM A653/A653M – Standard Specification for Steel Sheet, Zinc-Coated (Galvanized).

- EN 10346 – Continuously hot-dip coated steel flat products.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles.

- ISO 9227 – Corrosion tests in artificial atmospheres — Salt spray tests.

-

Reliable Water Tin Can Supplier | Durable & Sustainable Tinplate Containers

NewsNov.24,2025

-

Reliable Water Tin Can Suppliers for Durable and Sustainable Water Storage

NewsNov.24,2025

-

Water Tin Can Factory: Sustainable Solutions for Safe Water Packaging

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturer for Durable Infrastructure Solutions

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturers | Durable & Custom Iron Components

NewsNov.22,2025

-

Galvanized Malleable Iron Factories – Durable & Cost-Effective Industrial Solutions

NewsNov.22,2025