Kas . 30, 2024 20:15 Back to list

Leading Manufacturer of High-Quality Hot Dipped Galvanized Iron Products

Understanding Hot-Dipped Galvanized Iron A Comprehensive Overview

Hot-dipped galvanized iron has become an essential material in a variety of industries, prized for its durability, corrosion resistance, and overall cost-effectiveness. Understanding its manufacturing process, applications, and benefits can help various stakeholders, from builders to manufacturers, make informed decisions about its use in their projects.

What is Hot-Dipped Galvanized Iron?

Hot-dipped galvanizing is a process where iron or steel is coated with a layer of zinc to protect it from corrosion. This method involves immersing the iron or steel in a bath of molten zinc at temperatures around 450°C (842°F). The result is a strong, chemical bond between the zinc and the iron, forming a protective barrier that significantly extends the material's lifespan. This technique is particularly favoreddue to its effectiveness in preventing rust and degradation due to environmental factors.

The Manufacturing Process

The manufacturing process of hot-dipped galvanized iron involves several key steps

1. Surface Preparation Prior to galvanizing, the iron or steel surface must be thoroughly cleaned to remove any rust, scale, oil, or other contaminants. This is typically done through a combination of pickling with acidic solutions and mechanical cleaning.

2. Fluxing After cleaning, the metal is dipped into a flux solution, usually composed of zinc ammonium chloride. This step prevents the formation of oxides on the surface, ensuring that the zinc adheres properly during the galvanizing process.

3. Galvanizing The cleaned and fluxed metal is then immersed in molten zinc. The reaction occurs as the iron reacts with the zinc, forming various zinc-iron alloys at the surface, which contribute to the long-lasting protective properties of the coating.

4. Cooling and Inspection After galvanizing, the metal is withdrawn from the zinc bath and allowed to cool. The finished product undergoes rigorous inspection to ensure it meets quality standards, checking for coating thickness and adhesion quality.

Applications of Hot-Dipped Galvanized Iron

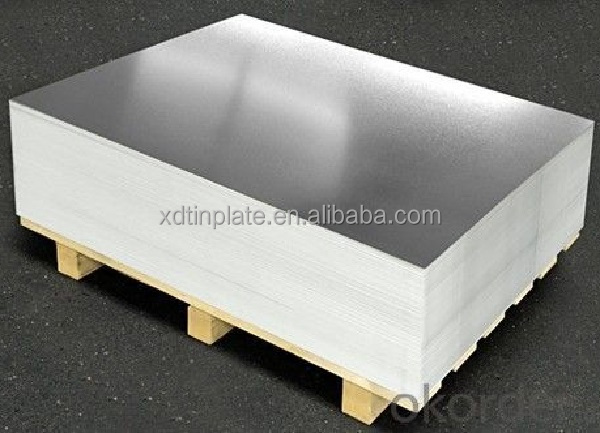

hot dipped galvanized iron manufacturer

Hot-dipped galvanized iron is utilized across numerous industries due to its unparalleled durability

- Construction Commonly used in building materials such as steel beams, columns, and roofing. The protective coating significantly extends the life of structural elements. - Manufacturing Many manufacturers use it for fabrication of products that require strength and resistance to harsh environments. - Agriculture Fencing, livestock handling equipment, and storage tanks made from hot-dipped galvanized iron are favorites in the agricultural sector.

- Automotive The automotive industry often employs hot-dipped galvanized components in vehicle manufacturing to prevent corrosion, ensuring vehicles remain in good condition over time.

Advantages of Hot-Dipped Galvanized Iron

One of the primary advantages of hot-dipped galvanized iron is its ability to withstand harsh environmental conditions. The zinc coating protects against rusting and degradation, even in moist or corrosive environments.

1. Longevity Products made from hot-dipped galvanized iron can last for decades with minimal maintenance.

2. Cost-Effectiveness While the initial investment may be slightly higher than non-galvanized iron, the long-term savings on maintenance and replacements make it a cost-effective choice.

3. Environmentally Friendly Zinc is a recyclable material, making hot-dipped galvanized products more eco-friendly.

4. Aesthetic Appeal The shiny, metallic finish of galvanized iron often provides a pleasing aesthetic, making it suitable for architectural applications.

Conclusion

Hot-dipped galvanized iron is a remarkable material that continues to be in high demand across various sectors due to its impressive properties and versatility. As industries evolve, the need for durable, cost-effective materials like hot-dipped galvanized iron will only increase, making it an important topic for manufacturers to understand. By recognizing the benefits and applications of this material, stakeholders can better position themselves to leverage its advantages in their respective fields.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025