Kas . 10, 2024 12:37 Back to list

Flat Roofing Membrane Production for Durable and Waterproof Solutions

Understanding Flat Roof Sheet Materials An Essential Guide for Manufacturers

In the world of construction, particularly when it comes to roofing, flat roofs have garnered significant attention due to their unique characteristics and advantages. Flat roof systems are increasingly favored in commercial and industrial projects, and regardless of the application, the choice of roofing materials is crucial. For manufacturers specializing in flat roof sheet materials, understanding the various options available and their respective benefits is essential in meeting market demands and enhancing the durability of roofing systems.

What Are Flat Roof Sheet Materials?

Flat roof sheet materials are specialized materials designed for use in flat roofing systems, which have a slope of 10 degrees or less. Unlike sloped roofs, flat roofs are easier to install and provide a substantial area for HVAC units, roof gardens, and more. The materials used for these roofs must be durable, waterproof, and capable of withstanding the elements, including UV radiation, temperature fluctuations, and moisture infiltration.

Common Types of Flat Roof Sheet Materials

1. TPO (Thermoplastic Polyolefin) TPO is a single-ply roofing membrane that is known for its energy efficiency and durability. It reflects sunlight, which helps in reducing heating costs, making it an environmentally friendly option. Manufacturers often prefer TPO due to its ease of installation and resistance to mold and punctures.

2. EPDM (Ethylene Propylene Diene Monomer) EPDM is a synthetic rubber material renowned for its excellent weather resistance and longevity. It is particularly popular in commercial applications because it can last over 30 years with minimal maintenance. EPDM is also highly elastic, allowing it to accommodate building movement without cracking.

3. PVC (Polyvinyl Chloride) PVC membranes are another popular choice for flat roofing. They are highly resistant to chemicals, UV rays, and fire, making them suitable for various environments. PVC roofing systems are also available in a variety of colors, further enhancing their appeal for aesthetic purposes.

4. Built-Up Roofing (BUR) Built-up roofing involves multiple layers of bitumen and fabric, providing excellent waterproofing and durability. This traditional roofing method is often chosen for its robustness and ability to withstand severe weather conditions. BUR is ideal for large flat roof areas.

5. Modified Bitumen This material is an evolution of built-up roofing and combines asphalt with modifiers to enhance its performance. Modified bitumen is available in both torch-down and self-adhering systems, offering flexibility in installation methods and added durability.

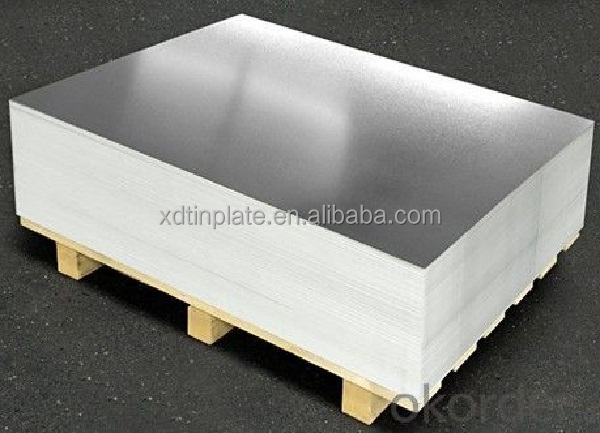

flat roof sheet materials manufacturer

Factors Influencing the Choice of Flat Roof Materials

When selecting flat roof sheet materials, manufacturers and builders must consider several factors

- Climate Regional weather conditions greatly influence material choice. For instance, areas prone to heavy rainfall might require more robust waterproofing systems, while hotter climates benefit from reflective materials.

- Cost Budget constraints often play a significant role in material selection. While some advanced materials like TPO and PVC may have a higher upfront cost, their longevity and reduced maintenance needs can lead to cost savings over time.

- Installation and Maintenance Ease of installation and maintenance requirements are critical considerations, particularly for large commercial projects. Some materials can be installed quickly and simply, reducing labor costs and minimizing the disruption to business operations during installation.

Innovations in Flat Roof Sheet Materials

The flat roofing industry has seen numerous innovations in material technology. Manufacturers are now focusing on creating more sustainable products, minimizing environmental impact while maximizing performance. Advances in material composition, such as incorporating recycled materials or enhancing energy efficiency, continue to shape the market.

Conclusion

For manufacturers of flat roof sheet materials, understanding the diverse array of options and their respective advantages is fundamental for meeting consumer demands and ensuring product longevity. With a focus on durability, energy efficiency, and environmental impact, manufacturers can play a pivotal role in the evolution of flat roofing solutions. As the construction landscape continues to change, staying informed and adaptable will be key to thriving in this competitive industry.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025