Eki . 30, 2024 22:10 Back to list

flat metal roofing sheets factories

Flat Metal Roofing Sheets Factories An Overview

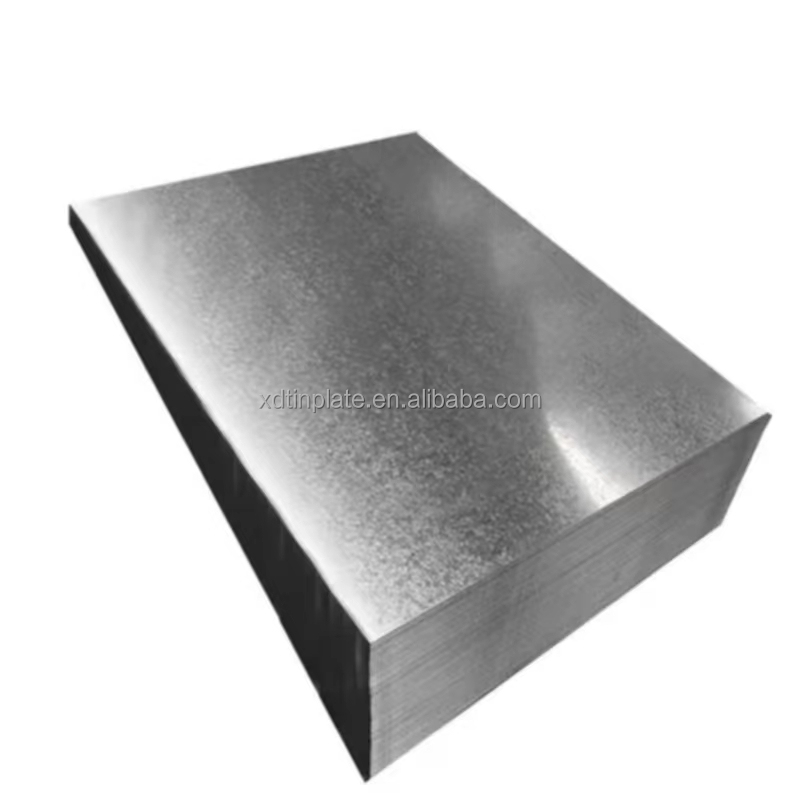

Flat metal roofing sheets have gained immense popularity in the construction industry due to their durability, aesthetic appeal, and cost-effectiveness. These roofing solutions are particularly sought after for both residential and commercial buildings. The emergence of specialized factories dedicated to manufacturing flat metal roofing sheets has propelled this trend, providing an array of innovative products to meet the growing demand.

Manufacturing Process

The production of flat metal roofing sheets involves several key steps. The initial stage includes selecting the appropriate metal, typically galvanized steel, aluminum, or copper, known for their resilience and ability to withstand harsh weather conditions. Once the raw material is acquired, it undergoes a cleaning process to remove any contaminants that could affect the quality of the final product.

After cleaning, the metal sheets are rolled into desired thicknesses using advanced machinery. This process not only enhances the sheet's strength but also allows for customization in terms of size and shape. Factories often utilize computerized systems to ensure precision cutting and shaping, improving efficiency and reducing wastage.

Once the sheets are shaped, they undergo various treatments, such as coating and painting, to enhance their resistance to corrosion and UV rays. These coatings come in numerous colors and finishes, catering to diverse architectural styles and personal preferences. The final stage involves quality control, where each sheet is inspected for defects before being packaged for distribution.

Sustainability Initiatives

flat metal roofing sheets factories

With increasing awareness of environmental issues, many flat metal roofing sheets factories are adopting sustainable practices. Manufacturers are increasingly using recycled materials in their products, which reduces the carbon footprint associated with production. Additionally, the longevity and recyclability of metal roofing sheets contribute to their sustainable profile, making them an environmentally friendly choice for builders and homeowners alike.

Global Market Trends

The demand for flat metal roofing sheets is on the rise globally, driven by urbanization, industrial growth, and the need for efficient building materials. In regions experiencing rapid economic development, such as Asia-Pacific and the Middle East, the construction industry is booming, leading to increased investments in roofing solutions. As a result, many factories are expanding their production capabilities to meet this growing demand.

In response to these market trends, manufacturers are also investing in research and development to innovate new products that incorporate advanced technologies. Features like improved insulation, energy efficiency, and smart roofing systems are becoming more popular, appealing to a more environmentally conscious consumer base.

Conclusion

Flat metal roofing sheets factories play a critical role in shaping the future of the construction industry. Through advanced manufacturing processes, sustainable practices, and a focus on innovation, these factories are not only providing high-quality roof solutions but are also contributing to the overall sustainability of the built environment. As the industry continues to evolve, the role of these factories will remain pivotal in addressing the challenges and demands of modern construction.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025