พ.ย. . 11, 2024 07:06 Back to list

galvanized iron floor flange factory

Exploring the Production of Galvanized Iron Floor Flanges

In the world of construction and industrial applications, the significance of reliable and durable components cannot be overstated. Among these, galvanized iron floor flanges play a pivotal role. These fittings, typically used to connect pipes and fixtures to surfaces, are essential for ensuring stability and integrity in plumbing and mechanical systems. At the heart of this process lies the galvanized iron floor flange factory, where precision engineering meets advanced manufacturing techniques.

Understanding Galvanized Iron

Galvanized iron refers to iron or steel that has been coated with a layer of zinc to prevent rust and corrosion. This protective layer is achieved through a process known as galvanization, which includes hot-dipping or electroplating. The result is a robust material that can withstand harsh environmental conditions, making it ideal for both indoor and outdoor applications. Galvanized iron's resilience provides longevity to structural elements, reducing the need for frequent replacements.

The Importance of Floor Flanges

Floor flanges are crucial components used to secure and stabilize pipework systems in various settings. They serve as the interface between the pipe and the floor or wall, providing a strong foundation for the piping system. By using floor flanges, contractors and engineers can maintain the alignment and support of pipes, which is vital for efficient water flow and pressure management.

In industrial applications, the use of floor flanges can significantly reduce installation time and improve safety. They facilitate the easy connection and disconnection of pipes, allowing for maintenance and repairs without extensive work. This is particularly important in facilities where downtime must be minimized.

The Manufacturing Process

The manufacturing of galvanized iron floor flanges involves several key stages

1. Material Selection The process begins with selecting high-quality iron or steel as the base material. The choice of material is critical, as it directly affects the strength and durability of the final product.

galvanized iron floor flange factory

2. Forging and Molding The selected material is then forged or molded into the desired shape. This may involve cutting, shaping, and forming processes that ensure precise dimensions and a smooth finish.

3. Galvanization Once the flanges are shaped, they undergo galvanization. This involves dipping the flanges into molten zinc or applying a zinc coating through electroplating. The result is a robust protective layer that enhances corrosion resistance.

4. Quality Control After galvanization, each floor flange is subjected to rigorous quality control measures. This includes checking for compliance with industry standards, dimensional accuracy, and integrity tests to ensure they can handle the pressures and loads they will encounter in use.

5. Packaging and Distribution Once approved, the flanges are packaged carefully to prevent damage during transportation. They are then distributed to various markets, including plumbing, HVAC (heating, ventilation, and air conditioning), and manufacturing industries.

The Future of Galvanized Iron Flange Manufacturing

As technology evolves, so does the manufacturing process for galvanized iron flanges. Factories are increasingly adopting automated systems and smart manufacturing techniques to enhance efficiency and reduce costs. Innovations such as advanced robotics, artificial intelligence, and improved galvanization methods are setting the stage for higher quality products with shorter production times.

Sustainability is also becoming a focal point in manufacturing. Factories are looking for ways to minimize waste and energy usage. Using recycled materials in the production of galvanized iron can significantly reduce the environmental impact.

Conclusion

Galvanized iron floor flange factories play an essential role in providing the industry with durable, reliable components that meet the demands of modern construction and manufacturing. With ongoing advancements in technology and a growing focus on sustainability, the future of galvanized iron flanges looks promising. As these factories continue to refine their processes, they will undoubtedly contribute to the development of more efficient and environmentally friendly infrastructure.

-

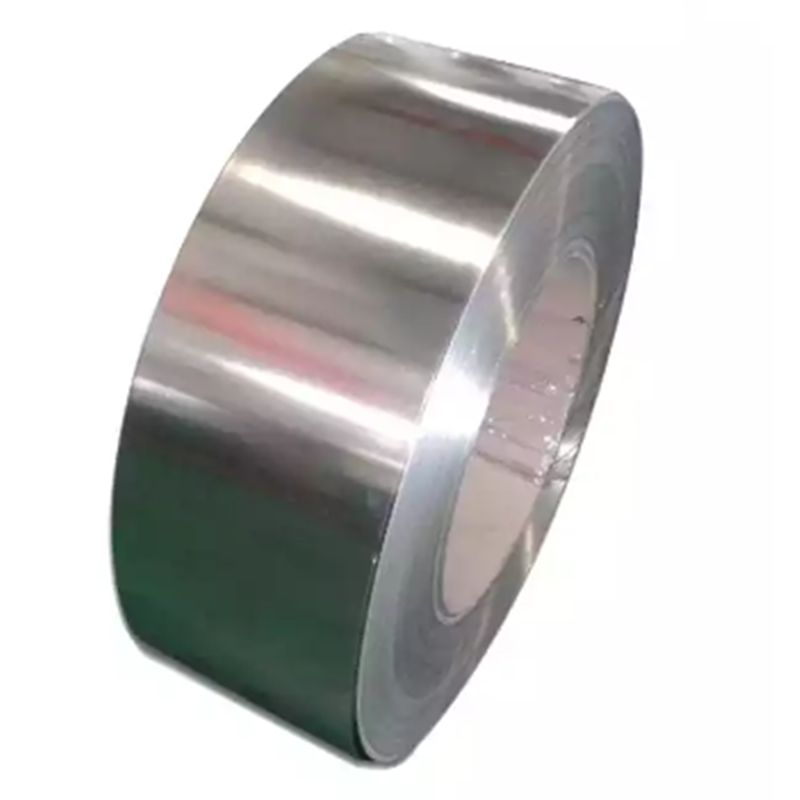

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025