Nov . 24, 2024 10:36 Back to list

steel tin plate factory

The Rise of Steel Tin Plate Factories An Overview

In the modern industrial landscape, steel tin plate factories play a crucial role in various sectors, from food packaging to construction. These factories symbolize the intersection of engineering and creativity, producing versatile materials that meet global demands. Understanding the intricacies of steel tin plate production offers insights into its importance and applications.

The Manufacturing Process

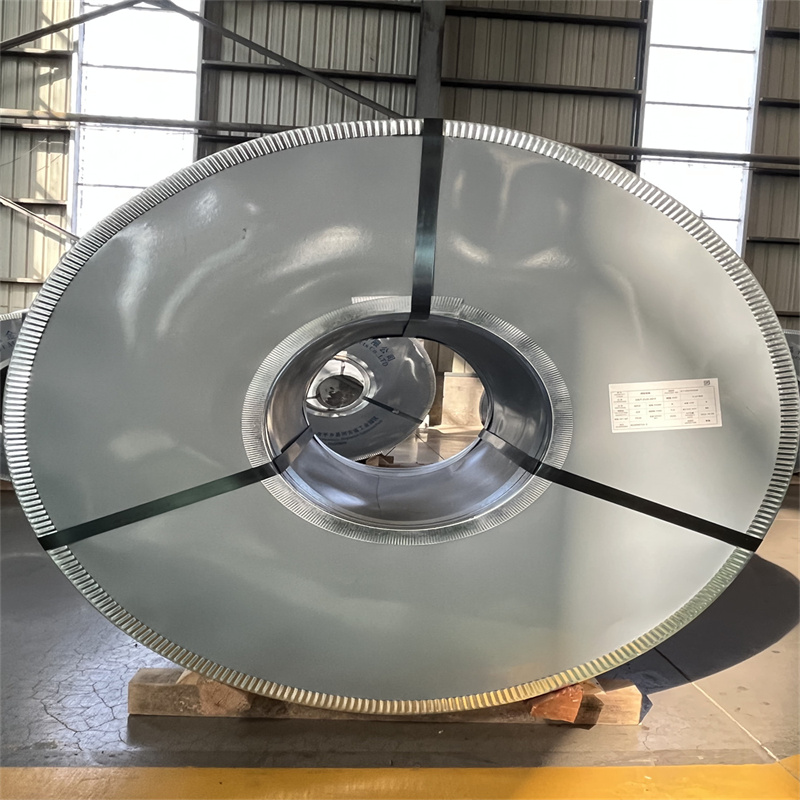

The production of steel tin plates involves several key steps. Initially, high-quality steel is sourced, usually in bulk, from reputable suppliers. This steel is then processed through techniques such as rolling, which gradually reduces its thickness. Rolling also improves the material's mechanical properties, making it more resilient and easier to handle.

After the initial shaping, the plates undergo a coating process. Tin is applied to one or both sides of the steel sheets, creating a protective barrier against corrosion. This tin layer is crucial as it enhances the durability and lifespan of the steel plates, enabling them to withstand humidity, exposure to chemicals, and other environmental factors.

Once coated, the sheets are cut, shaped, and packaged according to specific customer requirements. Quality control is integral throughout this process; it ensures that each batch meets industry standards and the precise specifications needed for various applications.

Applications of Steel Tin Plates

Steel tin plates are incredibly versatile and have numerous applications across different industries. One of the most common uses is in food packaging. The food and beverage sector relies heavily on tin-plated steel for containers such as cans, which preserve freshness and extend the shelf life of products. The non-reactive nature of tin ensures that food qualities remain uncompromised.

Additionally, steel tin plates are utilized in construction and infrastructure. They serve as durable sheets for roofing, siding, and exterior cladding, offering both aesthetic qualities and structural integrity. The ability to easily manufacture tin plates into various shapes and join them with other materials makes them a preferred choice in construction projects.

steel tin plate factory

Moreover, the automotive industry employs steel tin plates for fabricating components like fuel tanks and body panels

. Their lightweight nature combined with strength makes them an ideal material for reducing overall vehicle weight, thereby enhancing fuel efficiency.Environmental Considerations

Although steel tin plate factories contribute significantly to various sectors, they also face scrutiny regarding environmental impacts. Manufacturers are increasingly encouraged to adopt eco-friendly practices. Many factories have implemented recycling programs, ensuring waste materials, including excess steel and tin, are reused in the production process.

Furthermore, modern factories are investing in energy-efficient technologies that minimize their carbon footprints. Solar energy, for instance, is being harnessed in several plants, demonstrating a commitment to sustainability without sacrificing productivity.

Future Prospects

The future of steel tin plate factories looks promising. With advancements in technology, production processes are expected to become more efficient, improving yield and reducing waste. Innovations such as smart manufacturing and automation are set to enhance operational efficiency, allowing factories to respond swiftly to market demands.

Additionally, the growing emphasis on sustainable materials is likely to boost the demand for steel tin plates, as industries seek eco-friendly alternatives. As consumers become increasingly aware of environmental issues, the shift towards sustainable packaging and products will benefit manufacturers committed to sustainable practices.

Conclusion

In summary, steel tin plate factories are indispensable to a variety of industries, providing materials that are not only durable but also versatile. As they continue to evolve amidst environmental challenges and technological advancements, these factories are set to play a pivotal role in meeting future demands. Through innovation and sustainability, the steel tin plate industry is poised for enduring success, contributing significantly to global progress.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025