Nov . 20, 2024 00:37 Back to list

metal roof sheet types factories

Understanding Metal Roof Sheet Types and Factories

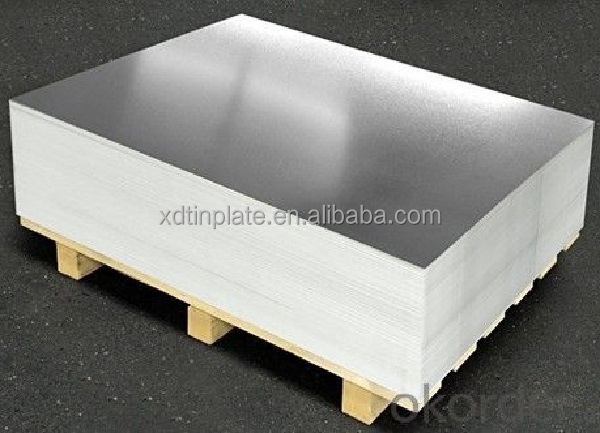

When it comes to roofing materials, metal sheets have gained significant popularity due to their durability, aesthetic appeal, and versatility. Among the various options available, different types of metal roof sheets cater to diverse architectural styles and functional needs. This article delves into the different metal roof sheet types and the factories that manufacture them, shedding light on their features, benefits, and applications.

Types of Metal Roof Sheets

1. Steel Roof Sheets Steel roof sheets, particularly those made from galvanized steel, are among the most commonly used metal sheets for roofing. They are known for their strength, affordability, and resistance to corrosion. Steel roof sheets can come in various profiles, including corrugated, standing seam, and tile effect. Their robustness makes them suitable for both residential and commercial buildings.

2. Aluminum Roof Sheets Aluminum is another popular choice for metal roofing. It is lightweight, resistant to corrosion, and offers excellent thermal insulation properties. Aluminum roof sheets are often used in coastal areas where saltwater exposure could lead to corrosion in other materials. These sheets come in various finishes and can be painted to enhance their aesthetic appeal.

3. Copper Roof Sheets Copper roof sheets are synonymous with luxury and unparalleled durability. Known for their longevity, copper can last for over a century with minimal maintenance. As copper oxidizes, it develops a unique patina that many homeowners find appealing. Although it is more costly than other metal roofing options, its aesthetic and functional benefits often justify the investment.

4. Zinc Roof Sheets Zinc is another premium option for metal roofing. It is highly durable, resistant to corrosion, and has a unique ability to self-repair minor scratches through a process known as patination. Zinc roof sheets can also be formed into intricate shapes, making them suitable for both modern and traditional designs.

5. Metal Shingles Metal shingles often mimic the appearance of traditional roofing materials like slate or wood, providing an attractive alternative for those who want the benefits of metal roofing without sacrificing aesthetics. Available in steel, aluminum, or copper, metal shingles offer both flexibility and visual appeal.

metal roof sheet types factories

Metal Roof Sheet Factories

The production of metal roof sheets involves advanced manufacturing processes capable of handling various materials. Factories typically employ cutting-edge technology to ensure precision and high-quality output. Here are key aspects of metal roof sheet factories

- Material Selection Factories source high-quality raw materials, such as galvanized steel, aluminum, copper, and zinc, ensuring their products meet safety and performance standards. - Manufacturing Process The production of metal roof sheets usually involves several steps, including roll forming, cutting, and finishing. Roll forming machines shape metal coils into specific profiles, while cutting machines ensure accurate sizing.

- Quality Control Reputable factories implement stringent quality control measures throughout the manufacturing process. This includes testing for durability, resistance to corrosion, and adherence to standards, ensuring that the final product performs well and lasts.

- Customization Many factories offer customization options, allowing clients to choose specific colors, coatings, and finishes that suit their building designs and preferences.

- Sustainability As sustainability becomes a priority, many metal roof sheet factories adopt eco-friendly practices. Metal roofing is often made from recycled materials and is itself recyclable, contributing to a more sustainable construction industry.

Conclusion

Metal roof sheets offer a myriad of options for homeowners and builders, with steel, aluminum, copper, and zinc leading the way. Each type of metal sheet has unique qualities that cater to specific needs and styles. Factories play a crucial role in producing these materials, utilizing advanced technology and maintaining high-quality standards. As construction trends evolve, metal roofing remains a respected choice, combining aesthetic versatility with functional performance—making it an ideal solution for many types of buildings.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025