Jan . 31, 2025 02:30 Back to list

corrugated roof sheet thickness suppliers

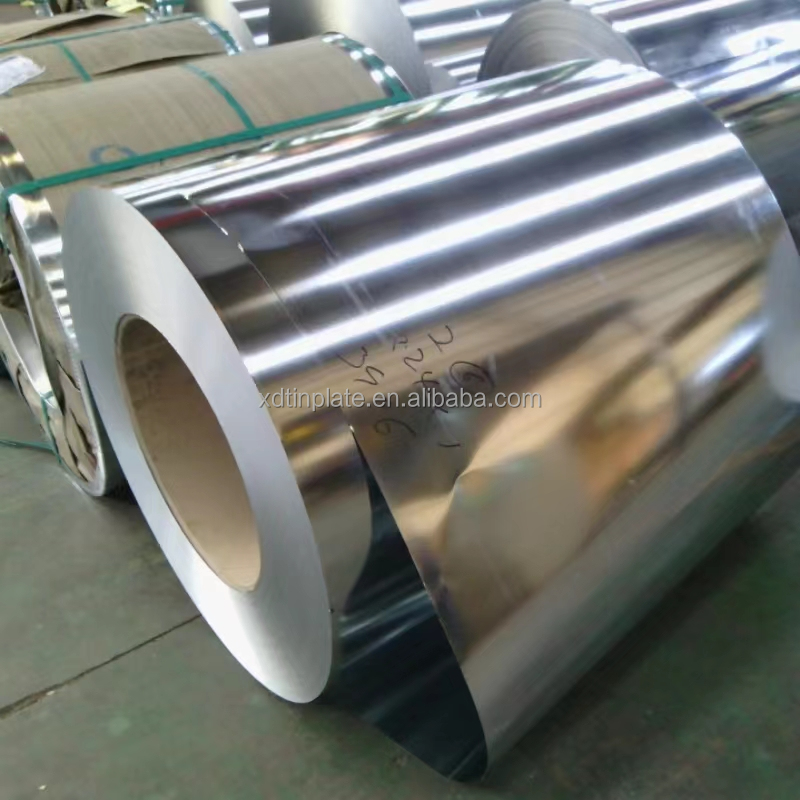

Choosing the right supplier for corrugated roof sheet thickness is a critical decision that impacts the durability, cost-effectiveness, and aesthetic value of your roofing project. This process requires an informed understanding of the materials, their applications, and the reputation of suppliers available in the industry.

The authority of a supplier in the market can often be gauged through their certifications and accreditations. Suppliers affiliated with recognized industry bodies or those possessing certifications such as ISO 9001 for quality management are more likely to uphold rigorous standards. Such credentials not only enhance the credibility of the supplier but also assure buyers of the authenticity and quality of the products they are purchasing. Perhaps one of the most critical aspects when selecting a supplier is trustworthiness. Genuine customer reviews and case studies often reveal the level of trust a supplier has garnered. Positive feedback regarding prompt delivery times, post-sale support, and warranty offerings are indicators of a supplier's reliability. Furthermore, suppliers that encourage client visits to their facility exhibit transparency, allowing customers to witness their production processes and gain confidence in their capabilities. In the digital age, a supplier’s online presence can also speak volumes about their reliability. A well-maintained, informative website with detailed product descriptions and technical specifications reflects their commitment to clarity and customer satisfaction. Moreover, suppliers actively engaging with clients via multiple channels — be it through social media, newsletters, or webinars — demonstrate a willingness to build lasting relationships and stay connected with their clientele. In conclusion, selecting the right corrugated roof sheet thickness supplier involves a combination of examining their product offerings, expertise, industry authority, and trustworthiness. Suppliers who excel in these domains provide not just products, but solutions tailored to meet the precise demands of various projects. By prioritizing such attributes, you can ensure that your investment in roofing materials leads to enhanced stability and longevity of your structures, thereby delivering long-term value.

The authority of a supplier in the market can often be gauged through their certifications and accreditations. Suppliers affiliated with recognized industry bodies or those possessing certifications such as ISO 9001 for quality management are more likely to uphold rigorous standards. Such credentials not only enhance the credibility of the supplier but also assure buyers of the authenticity and quality of the products they are purchasing. Perhaps one of the most critical aspects when selecting a supplier is trustworthiness. Genuine customer reviews and case studies often reveal the level of trust a supplier has garnered. Positive feedback regarding prompt delivery times, post-sale support, and warranty offerings are indicators of a supplier's reliability. Furthermore, suppliers that encourage client visits to their facility exhibit transparency, allowing customers to witness their production processes and gain confidence in their capabilities. In the digital age, a supplier’s online presence can also speak volumes about their reliability. A well-maintained, informative website with detailed product descriptions and technical specifications reflects their commitment to clarity and customer satisfaction. Moreover, suppliers actively engaging with clients via multiple channels — be it through social media, newsletters, or webinars — demonstrate a willingness to build lasting relationships and stay connected with their clientele. In conclusion, selecting the right corrugated roof sheet thickness supplier involves a combination of examining their product offerings, expertise, industry authority, and trustworthiness. Suppliers who excel in these domains provide not just products, but solutions tailored to meet the precise demands of various projects. By prioritizing such attributes, you can ensure that your investment in roofing materials leads to enhanced stability and longevity of your structures, thereby delivering long-term value.

Latest news

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025