okt . 22, 2024 13:36 Back to list

tin plate supplier manufacturer

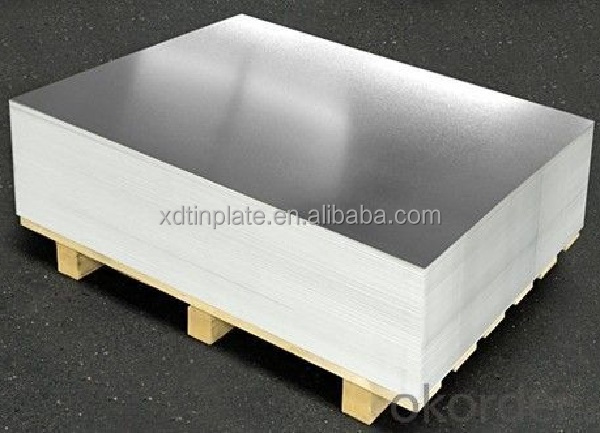

Tin Plate Supplier Manufacturer Meeting Industry Standards and Customer Demands

In today's fast-paced industrial landscape, the demand for high-quality materials is ever-increasing. Among these materials, tin plate has carved out a significant niche due to its versatility and protective qualities. This article explores the role of tin plate supplier manufacturers in meeting the needs of various industries, ensuring quality, and driving innovation.

Tin plate is primarily composed of steel that has been coated with a thin layer of tin. This coating protects the steel from corrosion and rust, enhancing its durability and extending its usability. As a result, tin plate is widely used in the production of cans, containers, and other packaging solutions, making it an essential material for sectors such as food and beverage, chemicals, and electronics.

A reliable tin plate supplier manufacturer plays a critical role in the supply chain. Such manufacturers are responsible for sourcing high-quality raw materials, employing advanced production techniques, and adhering to stringent industry standards. Importantly, they must ensure that their products meet the specific requirements of their customers, which can vary significantly based on the end application.

tin plate supplier manufacturer

Quality control is paramount in the tin plate manufacturing process. Suppliers must implement rigorous testing protocols to ensure that their products withstand harsh conditions and meet safety and regulatory standards. This includes testing for tin adhesion, corrosion resistance, and thickness uniformity. Manufacturers often seek certifications such as ISO 9001, which indicates that they have established quality management systems to consistently meet customer needs.

Furthermore, a tin plate supplier manufacturer must invest in research and development to stay competitive in the market. Innovations in coating technologies, for instance, can enhance the performance of tin plates, making them suitable for specialized applications. Manufacturers are also exploring eco-friendly options, such as recyclable and sustainable materials, to align with the growing emphasis on environmental responsibility. This not only meets consumer demand for greener products but also helps manufacturers stay ahead of regulatory changes that may impact the industry.

Collaboration with clients is another vital aspect of a successful tin plate supplier manufacturer. By fostering strong relationships with customers, manufacturers can better understand their needs and provide tailored solutions. This collaborative approach can lead to the development of custom products, specialized coatings, and improved supply chain logistics. Effective communication and responsiveness to customer inquiries also contribute to building trust and long-lasting partnerships.

In conclusion, tin plate supplier manufacturers are crucial players in various industries, providing essential materials that ensure product integrity and durability. By focusing on quality control, innovation, and customer collaboration, these manufacturers can meet the evolving demands of the market and contribute to the sustainability of their operations. As industries continue to grow and diversify, the role of tin plate suppliers will remain vital, driving advancements and enabling businesses to achieve their goals while prioritizing quality and environmental stewardship.

-

Affordable Mini EV Cars | Eco-Friendly Electric Vehicles for City Life

NewsJul.20,2025

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025