dec . 03, 2024 15:54 Back to list

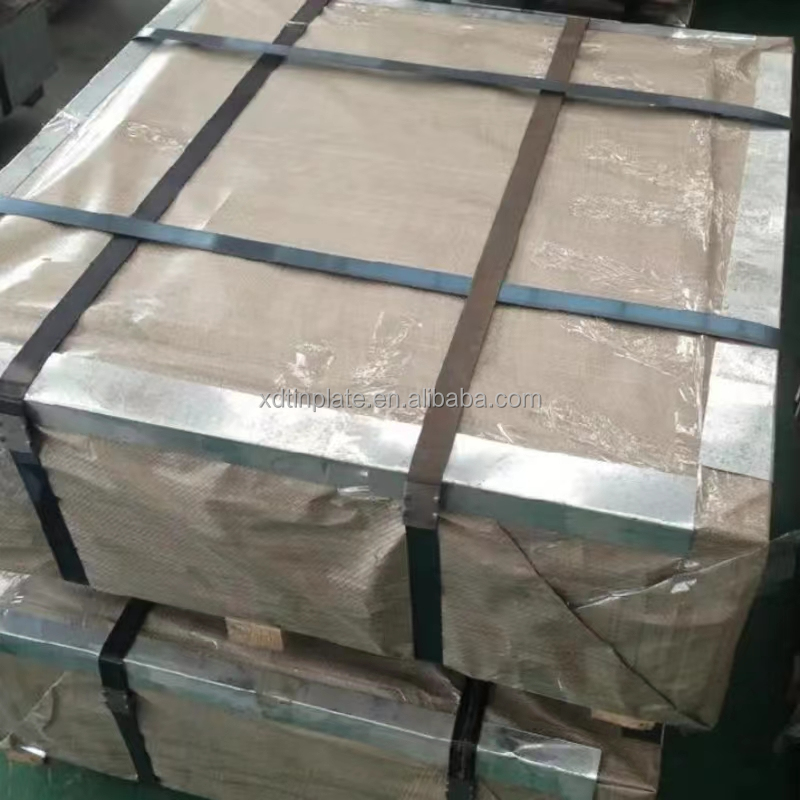

roof tin sheet manufacturers

The Evolution and Importance of Roof Tin Sheet Manufacturers

In the world of construction and architecture, the roofing materials used play a critical role in the structural integrity, aesthetic appeal, and overall durability of a building. Among these materials, tin sheets have long been favored for their lightweight, corrosion-resistant properties, and versatility. As a result, roof tin sheet manufacturers have become essential players in the construction industry, providing quality materials that meet the diverse needs of builders and homeowners alike.

The History of Tin Roofing

The use of tin for roofing dates back centuries, with its origins tracing to the 19th century when it became popular in North America and Europe. Initially, tin roofing was mainly crafted from iron sheets coated with tin to prevent rusting. This innovation led to the development of what we now recognize as “tinplate” – sheets of iron or steel coated with tin to create a durable and corrosion-resistant surface.

As industrialization progressed, the manufacturing techniques for producing tin sheets improved significantly. Modern roof tin sheets are typically made from galvanized steel or aluminum, offering enhanced durability and performance. Today’s manufacturers employ advanced techniques involving state-of-the-art machinery and automation, which have streamlined production processes, thereby reducing costs and increasing efficiency.

The Role of Roof Tin Sheet Manufacturers

Roof tin sheet manufacturers play a crucial role in the supply chain of construction materials. Their responsibilities include the selection of raw materials, the manufacturing process, quality control, and distribution. These manufacturers must adhere to strict industry standards to ensure that the final product meets safety and performance specifications.

Moreover, the manufacturers work closely with architects and engineers to provide tailored solutions that meet specific project requirements. This collaborative approach ensures that roof tin sheets not only serve functional purposes but also align with the design aesthetics of the building. With increasing demand for sustainable building materials, many manufacturers are now also focusing on eco-friendly production processes, using recycled materials wherever possible.

roof tin sheet manufacturers

Advantages of Roof Tin Sheets

Roof tin sheets offer numerous advantages that have solidified their popularity in both residential and commercial construction. One of the most significant benefits is their lightweight nature, which reduces the structural load on buildings. This characteristic makes them easy to transport and install, allowing for quicker project completion.

Additionally, tin sheets provide excellent protection against harsh weather conditions, including rain, snow, and hail. Their reflective surface also contributes to energy efficiency by reducing heat absorption, leading to lower cooling costs in warmer climates. Furthermore, with proper maintenance, tin roofs can last for several decades, making them a cost-effective choice in the long run.

The Future of Roof Tin Sheet Manufacturing

As the construction industry continues to evolve, roof tin sheet manufacturers must adapt to new trends and technologies. The growing emphasis on sustainable construction practices has prompted manufacturers to invest in research and development to produce environmentally friendly products. Innovations such as coatings that enhance energy efficiency and advanced corrosion resistance are becoming increasingly common.

Moreover, the rise of smart buildings has introduced new opportunities for manufacturers. The integration of smart technology in roofing systems, including sensors that monitor weather conditions and building performance, represents the future of tin roofing. Manufacturers who embrace these advancements are likely to lead the industry, catering to the changing demands of consumers and builders alike.

Conclusion

Roof tin sheet manufacturers are vital to the construction landscape, providing essential materials that contribute to the safety, durability, and aesthetic appeal of buildings. By leveraging advancements in technology and prioritizing sustainability, these manufacturers not only meet current market demands but also pave the way for future innovations in roofing solutions. As the industry continues to change, roof tin sheet manufacturers will remain at the forefront, shaping the skylines of tomorrow.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025