jan . 06, 2025 19:10 Back to list

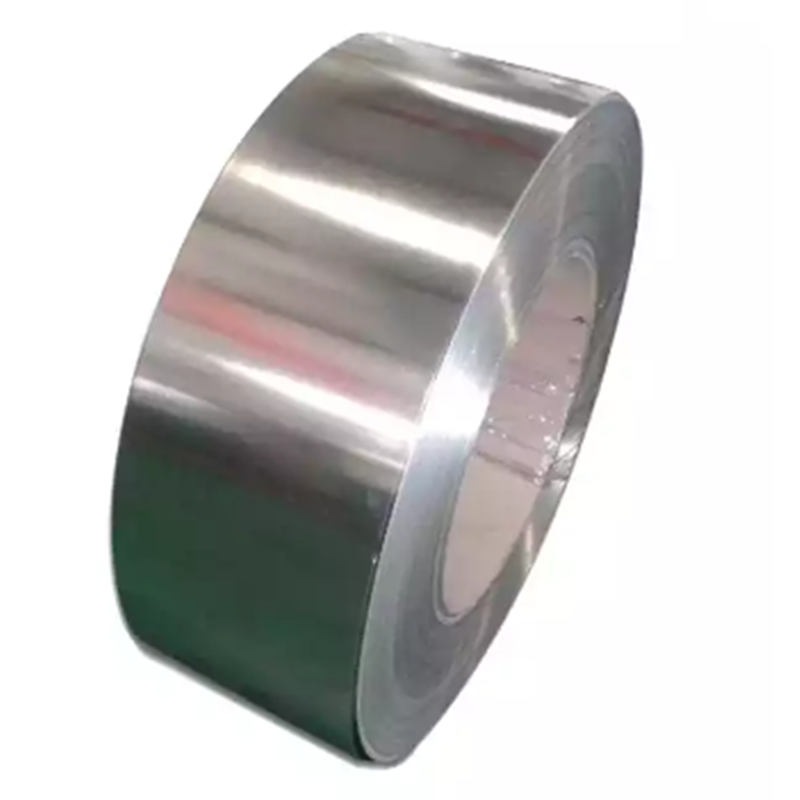

printed tinplate sheets

Printed tinplate sheets have revolutionized various industries by providing an innovative solution for packaging and product design

. These sheets are used predominantly in creating visually appealing and durable packaging for food, beverages, cosmetics, and more. Their application extends beyond mere aesthetics; printed tinplate sheets contribute significantly to product safety, longevity, and marketing efficacy.

The versatility of printed tinplate sheets lies in their exceptional strength and flexibility. Tinplate is composed of thin steel sheets coated with tin, which lends it a robust yet lightweight nature. This composition makes it ideal for packaging items that require protection against external elements such as moisture, air, and light. From a consumer's perspective, the longevity of goods stored in tinplate packaging enhances user experience, as products remain fresh and safe for consumption over extended periods.

Professionals in the packaging industry often emphasize the printability of tinplate sheets as a major advantage. The printing process, typically lithography, enables high-resolution graphics and vibrant colors to be applied directly to the metal substrate. This capability not only enhances the visual appeal of packaging but also serves as a powerful marketing tool. Brands can effectively communicate their identity and values through intricate designs and vibrant imagery, allowing for differentiation in a competitive market landscape.

Furthermore, printed tinplate sheets are lauded for their environmental benefits. Unlike other packaging materials that may contribute significantly to ecological footprints, tinplate is 100% recyclable. This quality aligns with the growing consumer demand for sustainable practices and materials. By choosing tinplate, companies demonstrate their commitment to environmental responsibility, which builds trust among eco-conscious consumers.

printed tinplate sheets

Expertise in the production and use of printed tinplate sheets is critical for businesses looking to leverage this material's benefits fully. Manufacturers employ sophisticated techniques to ensure the precision of coatings and the fidelity of reproduced images. This level of expertise is essential in maintaining the quality and durability of the final product, preventing issues such as peeling or fading that can compromise the package's integrity and appearance.

Authoritativeness in utilizing printed tinplate sheets stems from understanding the regulatory requirements that govern food and beverage packaging. Compliance with safety standards is non-negotiable, as it ensures the health and safety of consumers. Knowledgeable stakeholders in the tinplate manufacturing and design domain work in close collaboration with regulatory bodies to uphold these standards, reinforcing trust in their products' safety and reliability.

The trustworthiness of a brand employing printed tinplate sheets is further established through transparency in sourcing and production processes. By opting for ethically sourced raw materials and maintaining rigorous quality control measures, companies can provide assurance that their packaging meets the highest standards of quality and safety.

In summary, printed tinplate sheets offer a multifaceted advantage to businesses aiming to enhance their product offerings through superior packaging solutions. The integration of strength, printability, environmental sustainability, and strict adherence to safety regulations cements tinplate's position as a material of choice across diverse industries. Investing in this innovative packaging solution not only promises aesthetic and functional benefits but also aligns with broader consumer expectations for sustainability and safety in products.

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025