nov . 26, 2024 20:57 Back to list

Suppliers of Hot-Dipped Galvanized Iron Products for Various Applications and Projects

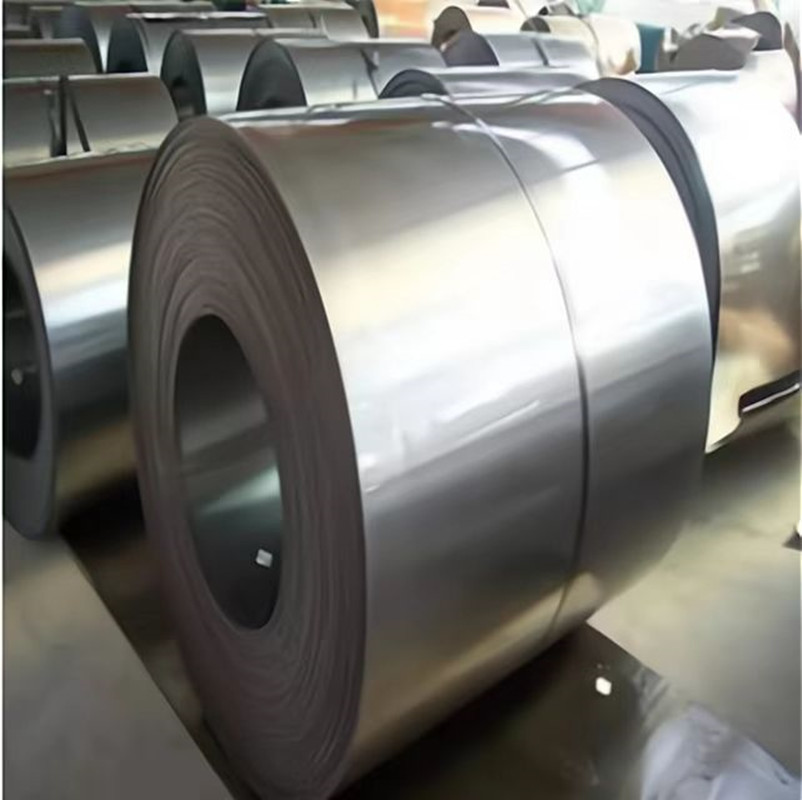

Understanding Hot-Dipped Galvanized Iron A Comprehensive Guide for Suppliers

Hot-dipped galvanized iron has become a cornerstone in various industries due to its outstanding properties of corrosion resistance, durability, and cost-effectiveness. Suppliers of this crucial material play an essential role in providing high-quality products that meet the demands of construction, manufacturing, and infrastructure development. In this article, we will delve into the benefits, applications, and sourcing considerations for hot-dipped galvanized iron.

What is Hot-Dipped Galvanized Iron?

Hot-dipped galvanization is a process in which iron or steel is coated with zinc to prevent corrosion. The method involves immersing the base metal into molten zinc, resulting in a metallurgically bonded coating. This technique not only protects the surface of the iron but also enhances its longevity, making it a preferred choice for many applications. The zinc layer acts as a sacrificial anode; even if the coating becomes scratched or damaged, the exposed iron is still protected by the surrounding zinc.

Advantages of Hot-Dipped Galvanized Iron

1. Corrosion Resistance The primary advantage of hot-dipped galvanized iron is its excellent resistance to rust and corrosion. The zinc coating protects against environmental factors such as moisture and oxygen, which are known to cause oxidation.

2. Longevity Products made from hot-dipped galvanized iron can last significantly longer than untreated metals. Typical lifespans can range from 20 to 50 years, depending on environmental conditions.

3. Cost-Effectiveness While the initial investment might be higher than non-galvanized alternatives, the long-term savings are substantial. Reduced maintenance and replacement costs make hot-dipped galvanized iron a financially wise choice.

4. Versatility This material is available in various shapes and sizes, making it applicable in numerous industries such as construction, automotive, agriculture, and manufacturing. From structural beams to fencing and roofing materials, its versatility is unmatched.

hot dipped galvanized iron suppliers

Applications of Hot-Dipped Galvanized Iron

The applications of hot-dipped galvanized iron are vast. In construction, it is often used for framing, roofing, and siding. Its corrosion resistance makes it ideal for outdoor structures, such as fences, railings, and power pylons. In the automotive industry, galvanized components are crucial in preventing rust and ensuring vehicle longevity. Additionally, agriculture employs this material for durable fencing and livestock enclosures.

Sourcing Considerations for Suppliers

When sourcing hot-dipped galvanized iron, there are several factors that suppliers must consider to ensure they provide quality products.

1. Standard Compliance It is crucial to work with manufacturers who adhere to industry standards and certifications, such as ASTM A123 or ISO 1461, to ensure product quality and reliability.

2. Quality Assurance Suppliers should conduct thorough inspections to ensure that the galvanization is uniform and free from defects. Quality assurance processes can minimize issues related to premature corrosion or coating failures.

3. Supplier Reputation Partnering with reputable manufacturers is essential. Suppliers should evaluate the manufacturing processes, material sourcing, and past performance of potential partners to ensure that they align with their standards.

4. Customization Many projects may require customized solutions. Suppliers should seek out manufacturers that offer tailored services to meet specific project requirements, whether related to size, shape, or additional coatings.

Conclusion

Hot-dipped galvanized iron has established itself as a vital material across multiple sectors due to its exceptional properties. As suppliers, understanding the material's benefits, diverse applications, and sourcing considerations can lead to better product offerings and satisfied customers. By focusing on quality and building strong partnerships with reliable manufacturers, suppliers can contribute significantly to the industries they serve, ensuring that projects remain durable and cost-effective for years to come.

-

Best Used Cars in Gaithersburg MD Top Gaithersburg Used Car Dealers

NewsJul.05,2025

-

Best PA Used Cars for Sale Reliable Ready Credit & Pyramid Used Cars Mike Hill Used Cars Deals

NewsJul.04,2025

-

Best Used Cars Kalamazoo Affordable & Reliable Vehicles for Sale in Michigan

NewsJul.04,2025

-

Car Parts Used Auto Parts Market – Affordable & Quality Car-Parts.com Selection

NewsJul.04,2025

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025