Nov . 29, 2024 22:45 Back to list

Innovative Tin Stash Box Manufacturers Creating Unique Storage Solutions

The Art of Crafting Tin Stash Box Factories

In the world of manufacturing, the creativity of artisans and the precision of technology merge to produce a variety of unique items. Among these, tin stash boxes hold a special place. These small containers, commonly made from tinplate, have not only practical uses but also aesthetic appeal, capturing the interest of consumers worldwide. The factories that produce these tin stash boxes combine traditional craftsmanship with modern innovation to meet a diverse market demand.

The History of Tin Stash Boxes

The origins of tin containers date back centuries, with tin being favored for its malleability and resistance to rust. Historically, tin boxes were used for a variety of purposes, including storing food, tobacco, and other valuables. As time progressed, artisans began to recognize the potential of designing more decorative and thematic boxes to appeal to different consumer tastes. Today, tin stash boxes are utilized for everything from keeping small items organized to serving as collectible souvenirs.

The Manufacturing Process

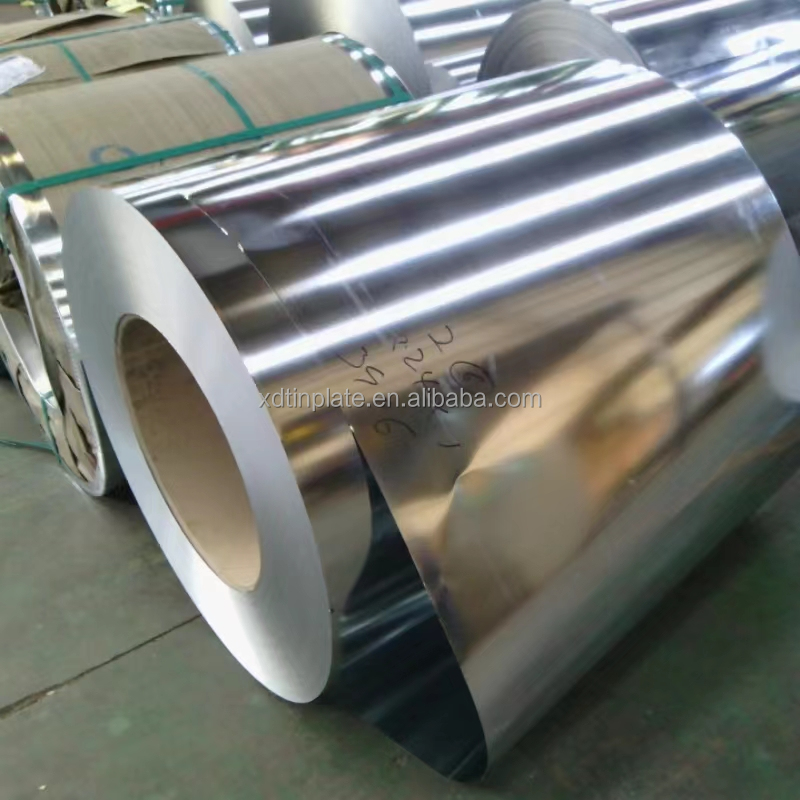

The manufacturing of tin stash boxes begins with the selection of high-quality tinplate, a material known for its durability and lightweight nature. Factories typically source this tinplate in large rolls, which are then cut into sheets tailored to the specific size and design of the stash boxes.

Once the sheets are prepared, the cutting process begins. Dies are utilized to stamp out the desired shapes, which ultimately form the body and lid of the boxes. This process requires careful planning and precision to ensure that each piece fits together perfectly. After cutting, the edges of the boxes are folded to create a seamless product that is both functional and aesthetically pleasing.

Next comes the printing phase, where designs are applied using various techniques, including lithography and screen printing. This step is crucial, as the artwork and branding elements significantly impact the appeal of the finished product. Factories often employ skilled graphic designers who collaborate closely with clients to create custom designs that resonate with their target audience. This attention to detail allows for a wide range of products, from vintage-inspired designs to contemporary graphics that appeal to younger consumers.

Once the printing is complete, the boxes undergo a sealing process to ensure they are airtight, which is particularly important for items that need protection from moisture. The production line also includes quality control inspections at various stages, ensuring that each box meets strict standards for durability and finish.

tin stash box factories

The Role of Sustainability

In recent years, sustainability has become a focal point within the manufacturing industry. Tin stash box factories have recognized the importance of eco-friendly practices. Many now implement recycling processes for scrap tin and utilize environmentally friendly inks and coatings in the printing phase. This shift not only appeals to environmentally conscious consumers but also helps companies reduce waste and lower their overall carbon footprint.

Additionally, some manufacturers are exploring alternatives to conventional packaging, opting for recyclable materials that can enhance the box's appeal as a sustainable product. By promoting and incorporating these practices, tin stash box factories can contribute positively to the environment while maintaining the quality and artistry that consumers expect.

The Market Demand

The demand for tin stash boxes continues to grow, spanning various sectors including food storage, cosmetics, home décor, and collectibles. Their versatility makes them an attractive option for businesses looking to package their products in an appealing way. Customization possibilities also allow businesses to use these boxes as marketing tools that enhance brand recognition.

As consumers embrace minimalism and organization, the trend toward unique, decorative storage solutions has gained momentum. Tin stash boxes not only meet the practical needs of consumers but also serve as stylish decorative pieces in homes, offices, and retail spaces.

Conclusion

In conclusion, the factories that produce tin stash boxes are more than just manufacturing hubs; they represent a blend of artistry, tradition, and modernity. From the history that informs their use to the innovative practices that guide production, these factories play a vital role in crafting items that resonate with consumers across the globe. As sustainability and customization continue to shape the industry, the future of tin stash boxes appears bright, ensuring their place in both practical applications and as beloved collectibles.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025