Nov . 23, 2024 22:18 Back to list

Printed Tinplate Sheet Manufacturing Facilities Overview and Insights

Exploring the World of Tinplate Sheet Printed Factories

In the age of advanced manufacturing and innovative packaging solutions, tinplate sheet printed factories play a vital role in a variety of industries. These factories specialize in the production and printing of tinplate, a versatile material widely used for packaging and other applications due to its durability, corrosion resistance, and aesthetic appeal.

Understanding Tinplate

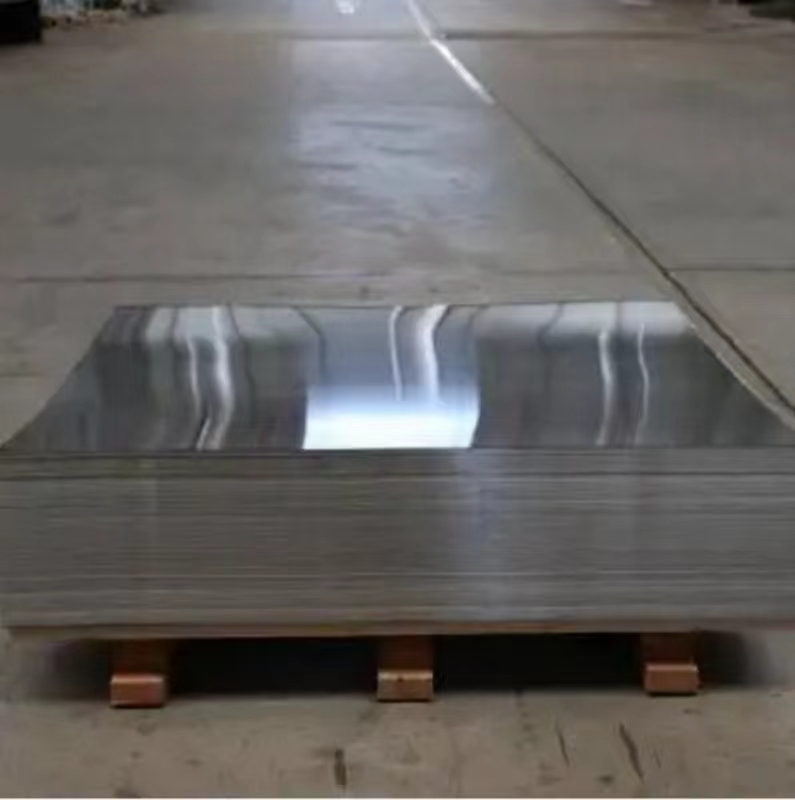

Tinplate is primarily made from thin sheets of steel that are coated with a layer of tin. This process not only protects the steel from rust but also enhances its ability to be printed upon. As a result, tinplate is favored for applications in food and beverage packaging, toys, electronics, and decorative items. The combination of strength and lightweight properties allows products made from tinplate to be transported easily while ensuring their integrity during storage.

The Manufacturing Process

The manufacturing of tinplate involves several critical steps. First, steel sheets are rolled to achieve the desired thickness. Next, the sheets undergo a tinning process, where they are coated with molten tin. The tinning not only enhances the appearance of the steel but also provides a barrier that protects against corrosion.

After the tinplate is produced, it is cut into sheets and prepared for printing. This is where tinplate sheet printed factories truly shine. Utilizing advanced printing technologies such as flexography, lithography, or digital printing, these factories can create vibrant and detailed designs on the tinplate surface. Customization is key in today’s market, and manufacturers often collaborate with clients to develop unique designs that resonate with consumers and reflect brand identity.

Benefits of Printed Tinplate

tinplate sheet printed factories

Printed tinplate offers numerous advantages. First and foremost, it serves as an effective branding tool. Eye-catching designs can attract consumers’ attention, helping products stand out on crowded shelves. Moreover, printed tinplate enhances the perceived value of a product. Packaging that looks good not only draws consumers in but also adds to the overall customer experience.

Additionally, tinplate is fully recyclable, aligning with global sustainability trends. As consumers become increasingly environmentally conscious, companies are seeking packaging solutions that minimize waste. By using tinplate, businesses can reduce their carbon footprint while still providing high-quality packaging options.

Industries Utilizing Printed Tinplate

Various industries benefit from the use of printed tinplate. The food and beverage industry is perhaps the most prominent user, with cans for soda, juices, and preserves all utilizing this material. The vibrant printing on these cans not only informs consumers about the product but also promotes brand loyalty.

Additionally, the beauty and cosmetics industry has recognized the potential of printed tinplate for packaging. Products such as creams, powders, and lip balms are often packaged in beautifully designed tin containers, appealing to consumers both functionally and aesthetically.

Moreover, the toy industry frequently employs printed tinplate for packaging, creating nostalgic and collectible products. The visual appeal of these packages plays a significant role in sales, making them more desirable to both children and collectors.

Conclusion

Tinplate sheet printed factories are crucial players in the manufacturing landscape, providing a unique blend of durability, versatility, and aesthetic appeal. The ability to print vibrant designs on tinplate not only enhances product visibility but also contributes to brand identity and consumer engagement. As industries continue to evolve, the demand for innovative packaging solutions will ensure that tinplate remains a favored choice. With sustainability at the forefront of consumer preferences, printed tinplate stands out as an environmentally responsible option that does not compromise on quality or design. Moving forward, these factories will continue to adapt and innovate, shaping the future of packaging in exciting new ways.

-

Discover Cheap Cars with GPT-4 Turbo Deals | Save Big Now

NewsAug.04,2025

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025