Jan . 10, 2025 12:24 Back to list

tin plates factory

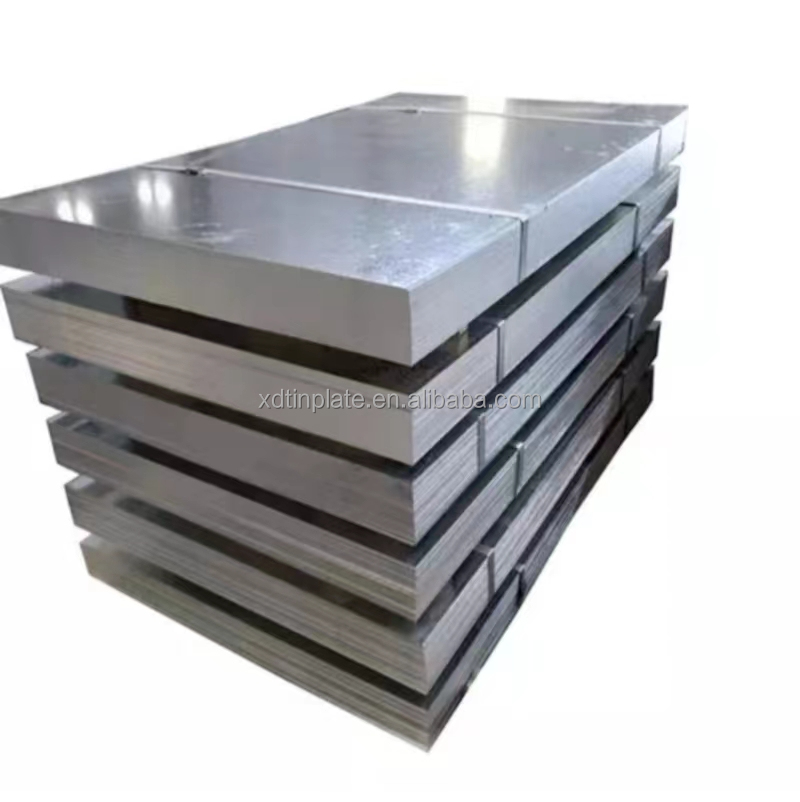

In the realm of industrial manufacturing, tin plates have long stood as a hallmark of reliability and versatility. As a seasoned SEO expert dissecting the keyword tin plates factory, it's crucial to delve into facets that underscore both authority and trustworthiness within the niche. Manufacturing tin plates is not just about producing sheets of metal; it involves intricate processes that demand precision, expertise, and a commitment to quality.

A proficient tin plates factory understands the diverse applications of its products, ranging from packaging and automotive components to electronics and construction materials. Such a factory doesn't just cater to immediate market demands but anticipates future technological advancements and ecological shifts. Their teams are often involved in R&D, exploring new coatings or materials that might enhance sustainability or reduce costs, reflecting an expertise that is both industry-driven and forward-thinking. An attribute often overlooked in discussions about industrial manufacturing is reliability. Client satisfaction hinges on a factory's ability to consistently deliver on time without compromising on quality. Leading tin plates factories have honed their logistics and supply chain operations to ensure punctual delivery, minimizing downtime for clients and maintaining production schedules across various industries. Furthermore, expert factories often maintain strong communication channels with their clients, offering post-sale support and engaging in feedback loops that inform future product iterations. Their customer service teams are knowledgeable not only about the products but also about their clients' specific industry needs. By fostering these relationships, the factory not only secures repeat business but also sets itself apart as a trusted partner in tin plate manufacturing. In summary, a tin plates factory steeped in experience and expertise establishes itself through a blend of technology, certifications, transparent operations, and proactive customer engagement. By maintaining rigorous quality standards and anticipating industry trends, it not only asserts its authority within the field but also cultivates trust, enhancing its standing as a stalwart in the manufacturing industry.

A proficient tin plates factory understands the diverse applications of its products, ranging from packaging and automotive components to electronics and construction materials. Such a factory doesn't just cater to immediate market demands but anticipates future technological advancements and ecological shifts. Their teams are often involved in R&D, exploring new coatings or materials that might enhance sustainability or reduce costs, reflecting an expertise that is both industry-driven and forward-thinking. An attribute often overlooked in discussions about industrial manufacturing is reliability. Client satisfaction hinges on a factory's ability to consistently deliver on time without compromising on quality. Leading tin plates factories have honed their logistics and supply chain operations to ensure punctual delivery, minimizing downtime for clients and maintaining production schedules across various industries. Furthermore, expert factories often maintain strong communication channels with their clients, offering post-sale support and engaging in feedback loops that inform future product iterations. Their customer service teams are knowledgeable not only about the products but also about their clients' specific industry needs. By fostering these relationships, the factory not only secures repeat business but also sets itself apart as a trusted partner in tin plate manufacturing. In summary, a tin plates factory steeped in experience and expertise establishes itself through a blend of technology, certifications, transparent operations, and proactive customer engagement. By maintaining rigorous quality standards and anticipating industry trends, it not only asserts its authority within the field but also cultivates trust, enhancing its standing as a stalwart in the manufacturing industry.

Next:

Latest news

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025