Jan . 29, 2025 06:17 Back to list

Rose gold small size metal tea coffee tin can

In the bustling world of food preservation, tin cans have established themselves as the go-to choice for manufacturers looking to ensure the longevity and safety of consumables. When selecting the right tin cans for canning food, it is crucial to partner with an experienced and reputable manufacturer. Not only do they provide quality products, but their expertise also ensures that every aspect from design to delivery is optimized for both functionality and food safety.

Trustworthiness in a tin can manufacturer is largely reflected in their transparency and commitment to quality control. A trustworthy manufacturer actively engages its clients in the manufacturing process, offering detailed insights into every step, from raw material sourcing to the production line. They provide transparency reports and labor assurances, prioritizing ethical practices and maintaining high standards for worker conditions and environmental responsibility. Feedback and testimonies from existing clients are invaluable indicators of a manufacturer’s reliability. Trustworthy manufacturers will have a stream of positive testimonials backing their reliability, problem-solving skills, and consistent delivery schedules. These endorsements act as social proof, reinforcing the company's trustworthiness to potential clients. In today’s competitive market, merely offering standard tin can options is no longer sufficient. Manufacturers need to provide custom solutions tailored to specific client needs. Whether it’s a unique design that improves shelf appeal, or specific innovations for product differentiation, a truly exceptional manufacturer has the flexibility and creativity to meet a wide array of customer demands while maintaining impeccable safety and quality standards. In conclusion, the journey from raw materials to a polished tin can ready for food canning is complex and layered with challenges. Choosing a tin cans manufacturer with experience, expertise, authoritativeness, and trustworthiness can significantly affect the quality and safety of the final canned product. As food and beverage companies continue to navigate this landscape, the value of a reliable manufacturing partner becomes even more critical. By focusing on these core values, businesses can ensure their products not only stand out on shelves but also deliver unparalleled safety and satisfaction to consumers.

Trustworthiness in a tin can manufacturer is largely reflected in their transparency and commitment to quality control. A trustworthy manufacturer actively engages its clients in the manufacturing process, offering detailed insights into every step, from raw material sourcing to the production line. They provide transparency reports and labor assurances, prioritizing ethical practices and maintaining high standards for worker conditions and environmental responsibility. Feedback and testimonies from existing clients are invaluable indicators of a manufacturer’s reliability. Trustworthy manufacturers will have a stream of positive testimonials backing their reliability, problem-solving skills, and consistent delivery schedules. These endorsements act as social proof, reinforcing the company's trustworthiness to potential clients. In today’s competitive market, merely offering standard tin can options is no longer sufficient. Manufacturers need to provide custom solutions tailored to specific client needs. Whether it’s a unique design that improves shelf appeal, or specific innovations for product differentiation, a truly exceptional manufacturer has the flexibility and creativity to meet a wide array of customer demands while maintaining impeccable safety and quality standards. In conclusion, the journey from raw materials to a polished tin can ready for food canning is complex and layered with challenges. Choosing a tin cans manufacturer with experience, expertise, authoritativeness, and trustworthiness can significantly affect the quality and safety of the final canned product. As food and beverage companies continue to navigate this landscape, the value of a reliable manufacturing partner becomes even more critical. By focusing on these core values, businesses can ensure their products not only stand out on shelves but also deliver unparalleled safety and satisfaction to consumers.

Latest news

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

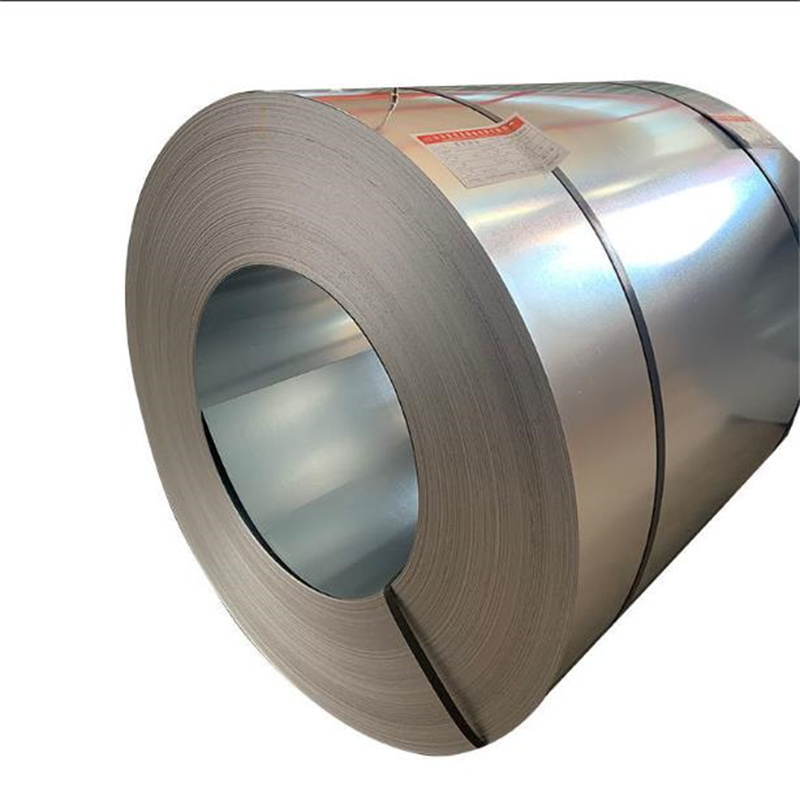

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025