Oct . 18, 2024 17:21 Back to list

Leading Manufacturers of Thin Tin Plate for Various Applications and Industries

Understanding the Role of Thin Tin Plate Manufacturers

In the realm of metal manufacturing, thin tin plates hold significant importance across various industries due to their unique properties and versatility. Thin tin plates, often produced through a process of tinning steel, are characterized by their lightweight nature, corrosion resistance, and ability to be easily shaped or welded. This article explores the role of thin tin plate manufacturers, their production processes, market applications, and the challenges they face in today's competitive landscape.

The Production Process

The production of thin tin plates typically begins with steel sheets that are cleaned and prepared for tinning. The steel is usually cold-rolled to achieve the desired thickness, with typical gauges ranging from 0.2 mm to 0.5 mm. The cleaning process involves removing any oxides or impurities through pickling and rinsing.

Once the steel sheets are prepared, they are subjected to a tinning process, which involves coating them with a thin layer of tin. This layer not only enhances the corrosion resistance of the steel but also provides an ideal surface for further processing, such as painting or printing. The tin coating is applied through several methods, including electroplating, hot-dipping, and mechanical plating, each offering unique advantages depending on the specific requirements of the end product.

Manufacturers must also adhere to strict quality control measures throughout the production process to ensure that the thin tin plates meet industry standards for thickness, finish, and tin coating weight, which is crucial for their performance in various applications.

Applications of Thin Tin Plates

Thin tin plates are extremely versatile and find applications across numerous industries. One of the most prominent uses is in the food packaging sector, where they are employed to manufacture cans and containers. The tin coating provides a protective barrier against corrosion, ensuring the longevity of food products while maintaining their freshness.

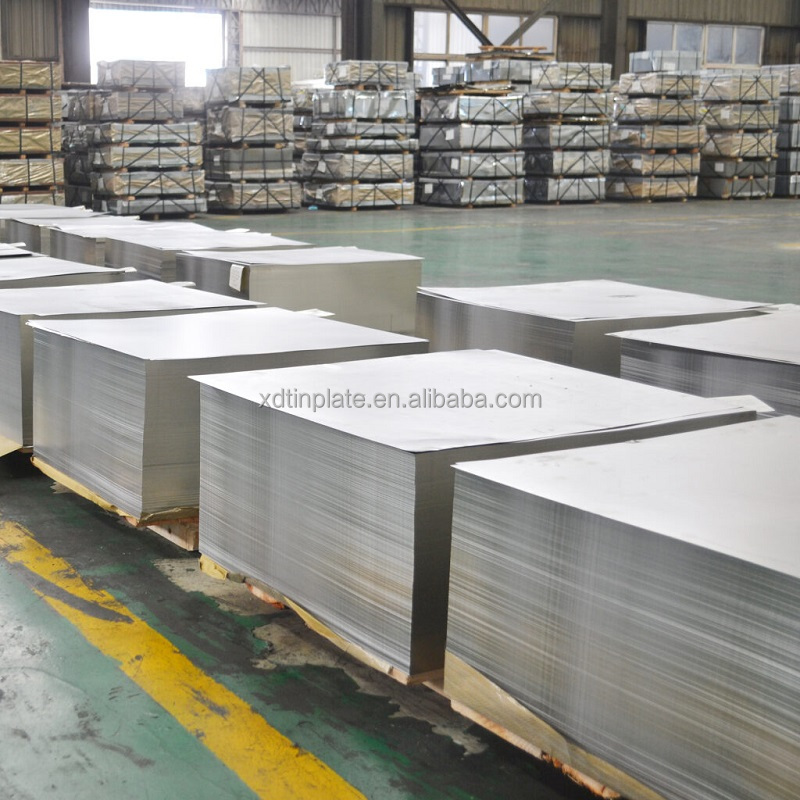

thin tin plate manufacturers

In the automotive industry, thin tin plates are often used in the production of electrical housings, connectors, and various components. Their excellent conductivity and resistance to rust make them ideal for such applications. Furthermore, the electronics industry utilizes thin tin plates for the manufacture of circuit boards and connectors, where durability and reliability are paramount.

Another significant sector is the construction and building industry, where thin tin plates serve as roofing materials and decorative elements. Their lightweight nature allows for easier handling and installation without compromising structural integrity.

Market Challenges

Despite the widespread use of thin tin plates, manufacturers face numerous challenges. One significant issue is the volatility of raw material prices. The cost of tin can fluctuate dramatically due to various factors, including supply chain disruptions, geopolitical tensions, and changes in mining production levels. These fluctuations can impact the overall cost of production, leading to tighter margins for manufacturers.

Moreover, environmental concerns and regulations surrounding the use of coatings and chemicals present additional challenges. Manufacturers are increasingly required to adopt more sustainable practices and comply with stringent environmental regulations. This may include investing in eco-friendly technologies or processes that minimize waste and reduce the environmental footprint.

Another challenge is the competition from alternative materials. As industries evolve and new materials emerge, some manufacturers may opt for alternatives to thin tin plates, such as aluminum or coated steels, which can offer similar benefits at potentially lower costs.

Conclusion

Thin tin plate manufacturers play a crucial role in several key industries by providing essential materials that enhance product performance and longevity. Despite the challenges they face, including fluctuating raw material prices and increasing competition from alternative materials, these manufacturers continue to innovate and adapt to market demands. Their commitment to quality and sustainability will determine their success in the ever-evolving manufacturing landscape. As industries continue to grow and diversify, the role of thin tin plates will remain significant, ensuring that manufacturers can meet the rigorous demands of their clients across various sectors.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025