Aug . 29, 2024 10:09 Back to list

Premium Thin Tin Plate Suppliers - Quality & Durability Guaranteed

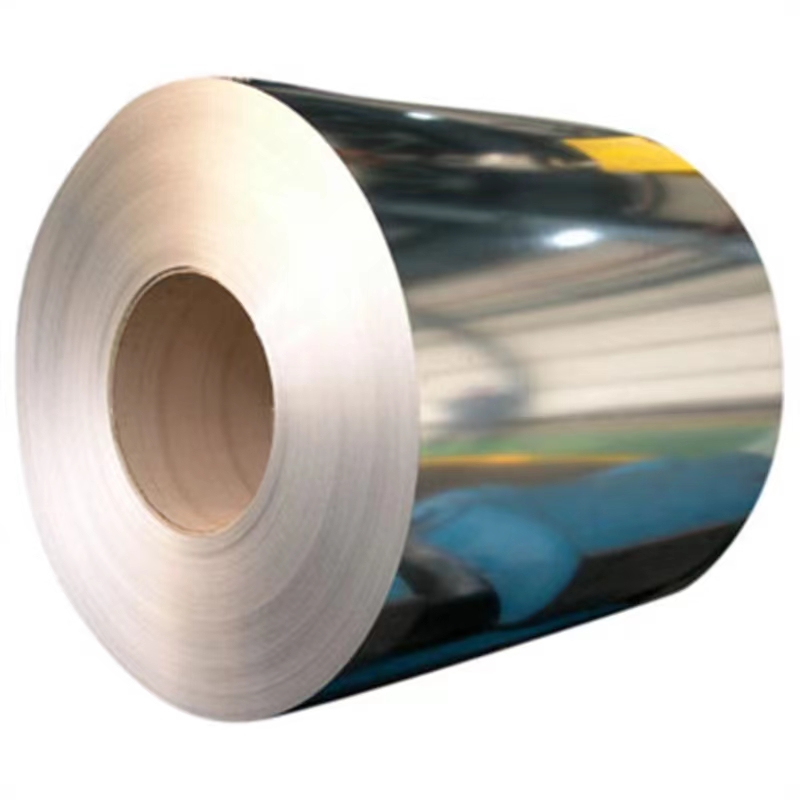

Thin Tin Plate Suppliers Essential Considerations and Market Overview

In today’s industrial landscape, thin tin plates are crucial components utilized in various applications, including packaging, electronics, and automotive industries. These lightweight yet durable sheets exhibit remarkable resistance to corrosion, making them ideal for products requiring longevity and protection from environmental factors. As demand for tin plates rises across different sectors, suppliers play a vital role in ensuring the availability of high-quality materials.

When searching for thin tin plate suppliers, several factors come into play that potential buyers should consider. First and foremost is the quality of the tin plates. Suppliers must meet or exceed industry standards in terms of thickness, finish, and resistance properties. High-quality tin plates should not only be lightweight but also have a smooth surface that allows for easy printing and coating. Therefore, prospective customers should seek suppliers that provide detailed specifications and proof of quality certifications.

Another critical consideration is the supplier's capacity for customization. Different industries might have unique requirements regarding size, coating type, and thickness. Suppliers offering customization options can cater to specific needs, ensuring that customers receive products tailored for their applications. This flexibility can be a significant advantage for companies looking to gain a competitive edge in their respective markets.

Pricing also plays a crucial role in selecting a supplier. It is important to compare prices among different suppliers to ensure competitive rates. However, customers should be cautious not to compromise on quality for a lower price. A well-established supplier might cost more initially but can provide long-term savings by reducing waste and improving product lifespan.

thin tin plate suppliers

Moreover, reliability and delivery times are essential aspects of the supplier's service. Businesses need to maintain consistent production schedules, and delays in the supply chain can result in costly setbacks. Therefore, it is advisable to choose suppliers known for their punctual delivery and strong communication practices. This reliability fosters a long-term partnership that can benefit both parties in the long run.

Additionally, suppliers with a strong track record of customer service can significantly enhance the purchasing experience. Efficient communication, prompt responses to inquiries, and after-sales support are critical components that can make a difference in supplier relationships.

Finally, the environmental impact of tin plate production is becoming a focal point for many companies. Suppliers that implement sustainable practices and contribute to reducing the carbon footprint can make a positive impression on eco-conscious businesses.

In conclusion, when evaluating thin tin plate suppliers, it is essential to consider quality, customization options, pricing, reliability, customer service, and sustainability practices. By doing so, companies can ensure they choose a supplier that not only meets their material needs but also contributes positively to their supply chain and long-term success. As industries continue to evolve, the role of suppliers will remain crucial in providing the materials necessary for innovation and growth.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025