Aug . 06, 2024 02:51 Back to list

Supplier Prices for Galvanized Iron Scrap and Related Market Trends to Consider

The Landscape of Galvanized Iron Scrap Prices A Supplier's Perspective

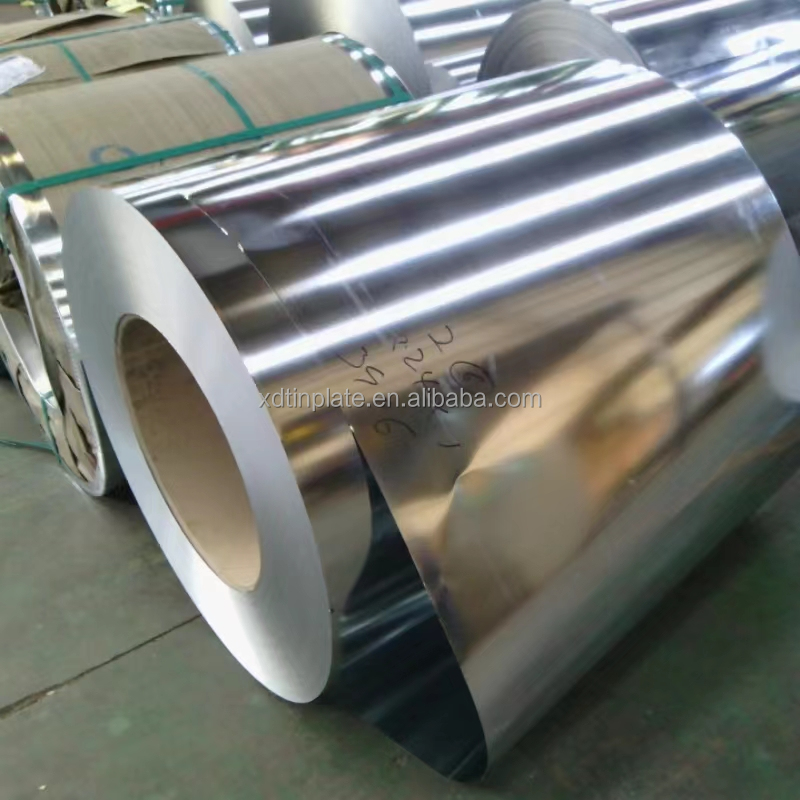

Galvanized iron, known for its remarkable resistance to corrosion due to its zinc coating, has become an essential material across various industries, including construction, automotive, and manufacturing. With the growing demand for sustainable practices and recycling, galvanized iron scrap has gained significant attention in the market. Understanding the dynamics of galvanized iron scrap prices is crucial for suppliers, buyers, and recyclers alike.

Factors Influencing Galvanized Iron Scrap Prices

The pricing of galvanized iron scrap is influenced by several key factors. First and foremost, the global steel market plays a vital role. Since galvanized iron is derived from steel, any fluctuations in steel prices directly affect the pricing of its scrap. For instance, when the demand for new steel rises, scrap prices often follow suit as manufacturers seek out cheaper alternatives. Conversely, if there is an oversupply of steel, scrap prices may decline.

Another significant factor is the supply and demand ratio. Economic growth in developing countries has led to an increased need for construction materials, which in turn raises the demand for galvanized iron and its scrap. Suppliers must closely monitor these trends to adjust their buying and selling strategies accordingly.

Furthermore, the quality of the scrap itself can greatly affect its price. Clean, high-grade galvanized iron scrap commands a premium price as it can be recycled with minimal processing. In contrast, contaminated or mixed-grade materials may fetch lower prices due to the additional costs associated with processing and sorting.

Regional Variations in Pricing

galvanized iron scrap price supplier

Galvanized iron scrap prices can vary widely based on geographic locations. In regions where industrial activity is booming, such as parts of Asia and North America, prices tend to be higher due to robust demand. In contrast, regions with slower economic growth may experience lower prices. Suppliers often need to be agile, adjusting their operations and pricing based on local market conditions.

Additionally, transportation costs play a significant role in regional pricing. Suppliers must account for logistics when determining their pricing strategy. For instance, suppliers situated near large industrial centers may have lower transportation costs, allowing them to offer more competitive prices. Conversely, suppliers in remote areas may have to factor in higher freight costs, influencing their pricing structures.

The Role of Sustainability

As the world shifts towards more sustainable practices, the recycling of galvanized iron scrap is becoming increasingly important. Manufacturers are looking for ways to reduce their carbon footprint, and recycling scrap metal is one of the most effective methods. This has sparked a growing interest in the galvanized iron scrap market, leading to increased investments in recycling capabilities and infrastructure.

Suppliers who embody sustainable practices, such as implementing efficient recycling processes and minimizing waste, can position themselves advantageously in the market. Consumers are becoming more conscientious about their purchases, often opting for suppliers that prioritize sustainability.

Conclusion

In conclusion, the galvanized iron scrap market presents a complex landscape shaped by various factors, including global steel prices, supply and demand dynamics, regional profitability, and sustainability trends. As a supplier, staying informed about these elements is crucial for navigating the market effectively. By adjusting strategies to align with current conditions and embracing sustainable practices, suppliers can not only ensure their profitability but also contribute positively to the larger goal of environmental sustainability. The future of galvanized iron scrap looks promising, provided that suppliers harness these insights to drive their business forward.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025