Jul . 27, 2024 18:20 Back to list

Supplier of Durable Sheet Metal Roof Solutions to Combat Rust and Enhance Longevity

Understanding Sheet Metal Roof Rust and Finding the Right Supplier

Sheet metal roofing has gained popularity in recent years due to its durability, longevity, and aesthetic appeal. However, one significant concern that comes with this robust roofing material is rust. Rust can diminish the visual appeal of a roof, compromise its structural integrity, and lead to more costly repairs over time. Therefore, finding a reliable supplier specializing in rust-resistant sheet metal roofing is crucial for homeowners and contractors alike.

The Nature of Rust in Sheet Metal Roofing

Rust is the result of a chemical reaction between iron, oxygen, and moisture, which leads to the formation of iron oxide. Sheet metal roofs are typically made from steel, which is susceptible to rusting if not properly coated or maintained. Factors such as geographical location, climate, and altitude can significantly influence the rate at which rust forms on metal roofing. Areas with high humidity, heavy rainfall, and significant temperature changes are particularly prone to rust-related issues.

To combat rust, many manufacturers apply protective coatings to their metal sheets. These coatings may include galvanization (zinc coating), paint finishes, and specialized rust inhibitors. When seeking a supplier, it is essential to inquire about the types of coatings available and their longevity in various environmental conditions.

Choosing the Right Supplier

Selecting the right supplier for sheet metal roofing involves assessing several key factors.

1. Quality of Materials Not all sheet metal is created equal. Look for suppliers that offer high-quality, corrosion-resistant materials. Research the types of steel used, such as Galvalume or stainless steel, which are known for their resistance to rust.

2. Product Warranty A reliable supplier should stand by the quality of their products. Look for suppliers that offer warranties covering both the material and the protective coatings. A robust warranty can provide peace of mind and assurance of long-term performance.

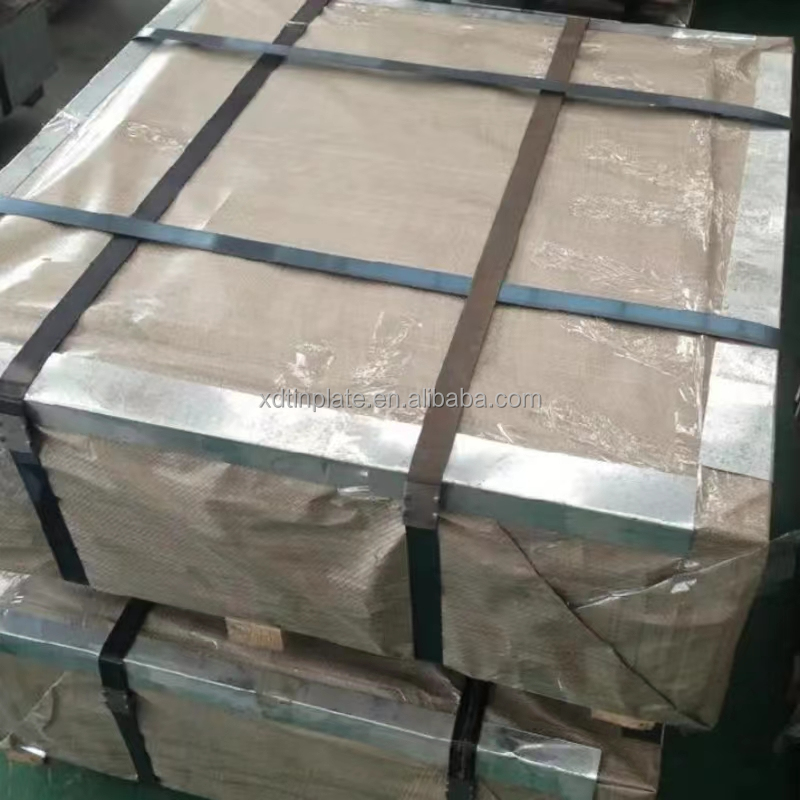

sheet metal roof rust supplier

3. Range of Products Depending on your specific needs, you may require various styles and finishes of sheet metal roofing. A good supplier will offer a wide range of products, including different colors, textures, and profiles.

4. Expertise and Support A knowledgeable supplier can offer invaluable advice not only on the products but also on installation practices to prevent rust. Consider suppliers that provide technical support and resources to help you make informed decisions.

5. Customer Reviews and Reputation Research the supplier's reputation within the industry and read customer reviews. Word-of-mouth recommendations from contractors and industry professionals can provide insight into the reliability and quality of the supplier’s products.

Maintenance Tips for Rust Prevention

While choosing a reliable supplier is crucial, proper maintenance of your sheet metal roof is equally important. Regular inspections should be conducted to identify any signs of rust or deterioration. Keeping the roof clean and free from debris can help prevent moisture accumulation, which contributes to rust.

In regions where snowfall is common, ensuring proper drainage is vital. Accumulated snow can hold moisture against the metal surface longer than expected, increasing the risk of rust. Also, promptly addressing any scratches or damages to the protective coating will help maintain the roofing's integrity.

Conclusion

Rust is a formidable adversary when it comes to the longevity of sheet metal roofing. By selecting a reputable supplier that offers high-quality, rust-resistant materials, and implementing regular maintenance practices, homeowners and contractors can effectively mitigate the risk of rust. With the right approach, sheet metal roofing can provide long-lasting protection and beauty for years to come.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025