Jun . 15, 2024 18:30 Back to list

Steel mill black plate factories.

The Tin Mill Black Plate Factories An Industrial Marvel

In the heart of industrial zones, where smokestacks kiss the sky and the rhythmic hum of machinery echoes through the air, lie the tin mill black plate factories. These manufacturing behemoths are a testament to human ingenuity and the relentless pursuit of technological advancement.

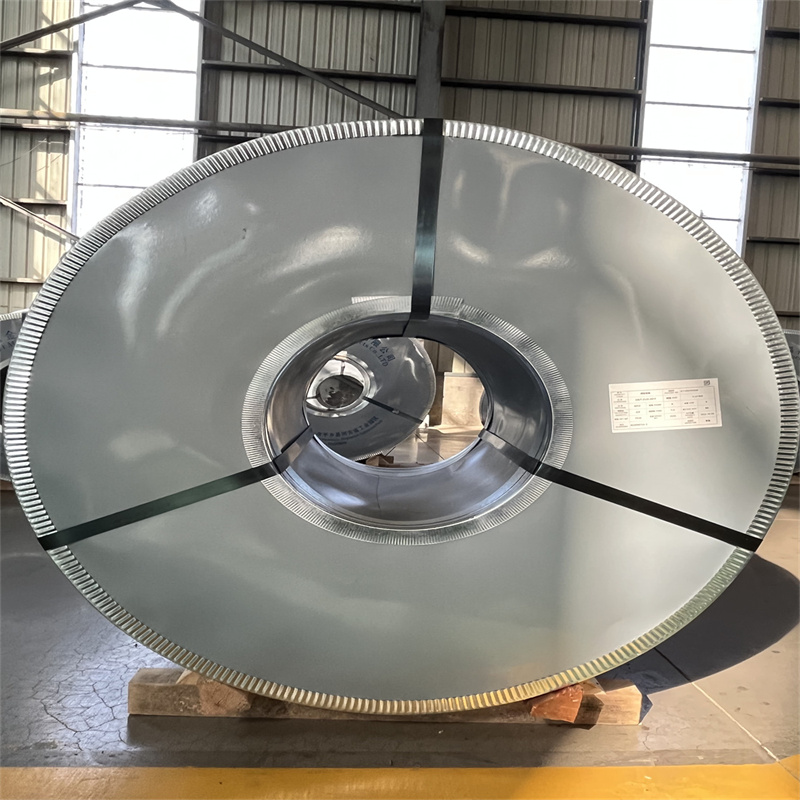

The process of creating tin mill black plates is a fascinating blend of science and art. It begins with high-quality raw materials that are meticulously selected to ensure the end product's durability and strength. The tin, often sourced from sustainable mines around the world, is then melted in furnaces that reach temperatures of over 1,000 degrees Celsius. This molten tin is poured into molds, where it cools and solidifies into the shape of the desired plate.

However, the true magic happens during the milling process. The plates undergo a series of rolling operations that refine their thickness and improve their surface quality. Each pass through the mill's heavy rollers makes the plates thinner and more precise, eventually resulting in the famous tin mill black plate. These plates are not only visually striking with their sleek black finish but also boast exceptional corrosion resistance and strength.

The applications for these plates are as diverse as they are essential. They find use in construction, automotive industries, marine applications, and even in the production of household appliances They find use in construction, automotive industries, marine applications, and even in the production of household appliances They find use in construction, automotive industries, marine applications, and even in the production of household appliances They find use in construction, automotive industries, marine applications, and even in the production of household appliances

They find use in construction, automotive industries, marine applications, and even in the production of household appliances They find use in construction, automotive industries, marine applications, and even in the production of household appliances tin mill black plate factories. Their ability to withstand harsh environments and resist wear and tear make them a valuable commodity in various sectors.

But the impact of these factories extends beyond their products. They are economic powerhouses, providing jobs for thousands of workers and contributing significantly to local and national economies. The skilled labor force that operates the machinery, monitors the quality, and ensures safety is the backbone of these factories.

Despite the inevitable challenges faced by industries in the modern era, such as environmental concerns and market fluctuations, the tin mill black plate factories continue to innovate. They strive to reduce their ecological footprint by implementing cleaner production methods and recycling waste. They also adapt to shifting demands by researching new alloys and improving efficiency.

In conclusion, the tin mill black plate factories stand as monuments to industrial prowess. They embody the spirit of progress, employing cutting-edge technology to manufacture a product that has become an integral part of our modern world. As we look towards the future, these factories remind us of our capacity to transform raw materials into tools that shape our societies and propel us forward.

tin mill black plate factories. Their ability to withstand harsh environments and resist wear and tear make them a valuable commodity in various sectors.

But the impact of these factories extends beyond their products. They are economic powerhouses, providing jobs for thousands of workers and contributing significantly to local and national economies. The skilled labor force that operates the machinery, monitors the quality, and ensures safety is the backbone of these factories.

Despite the inevitable challenges faced by industries in the modern era, such as environmental concerns and market fluctuations, the tin mill black plate factories continue to innovate. They strive to reduce their ecological footprint by implementing cleaner production methods and recycling waste. They also adapt to shifting demands by researching new alloys and improving efficiency.

In conclusion, the tin mill black plate factories stand as monuments to industrial prowess. They embody the spirit of progress, employing cutting-edge technology to manufacture a product that has become an integral part of our modern world. As we look towards the future, these factories remind us of our capacity to transform raw materials into tools that shape our societies and propel us forward.

They find use in construction, automotive industries, marine applications, and even in the production of household appliances They find use in construction, automotive industries, marine applications, and even in the production of household appliances

They find use in construction, automotive industries, marine applications, and even in the production of household appliances They find use in construction, automotive industries, marine applications, and even in the production of household appliances tin mill black plate factories. Their ability to withstand harsh environments and resist wear and tear make them a valuable commodity in various sectors.

But the impact of these factories extends beyond their products. They are economic powerhouses, providing jobs for thousands of workers and contributing significantly to local and national economies. The skilled labor force that operates the machinery, monitors the quality, and ensures safety is the backbone of these factories.

Despite the inevitable challenges faced by industries in the modern era, such as environmental concerns and market fluctuations, the tin mill black plate factories continue to innovate. They strive to reduce their ecological footprint by implementing cleaner production methods and recycling waste. They also adapt to shifting demands by researching new alloys and improving efficiency.

In conclusion, the tin mill black plate factories stand as monuments to industrial prowess. They embody the spirit of progress, employing cutting-edge technology to manufacture a product that has become an integral part of our modern world. As we look towards the future, these factories remind us of our capacity to transform raw materials into tools that shape our societies and propel us forward.

tin mill black plate factories. Their ability to withstand harsh environments and resist wear and tear make them a valuable commodity in various sectors.

But the impact of these factories extends beyond their products. They are economic powerhouses, providing jobs for thousands of workers and contributing significantly to local and national economies. The skilled labor force that operates the machinery, monitors the quality, and ensures safety is the backbone of these factories.

Despite the inevitable challenges faced by industries in the modern era, such as environmental concerns and market fluctuations, the tin mill black plate factories continue to innovate. They strive to reduce their ecological footprint by implementing cleaner production methods and recycling waste. They also adapt to shifting demands by researching new alloys and improving efficiency.

In conclusion, the tin mill black plate factories stand as monuments to industrial prowess. They embody the spirit of progress, employing cutting-edge technology to manufacture a product that has become an integral part of our modern world. As we look towards the future, these factories remind us of our capacity to transform raw materials into tools that shape our societies and propel us forward. Latest news

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025