Dec . 03, 2024 18:29 Back to list

small metal tool boxes factory

A Glimpse into the World of Small Metal Tool Boxes The Factory Experience

In the fast-paced world of manufacturing, small metal tool boxes play a vital role in the organization and storage of tools and equipment. These sturdy containers not only offer durability but also reflect the meticulous craftsmanship that goes into their production. This article aims to explore the intricacies of a factory that specializes in the manufacturing of small metal tool boxes.

The Factory Environment

Walking into a small metal tool box factory, one is immediately struck by the organized chaos of machinery and human activity. The rhythmic sounds of metal being cut, welded, and assembled fill the air, creating a unique harmony of industry. The factory layout is designed for efficiency, with each workstation dedicated to a specific process in the tool box manufacturing cycle. This allows for high productivity while ensuring that each box meets strict quality standards.

Materials and Design

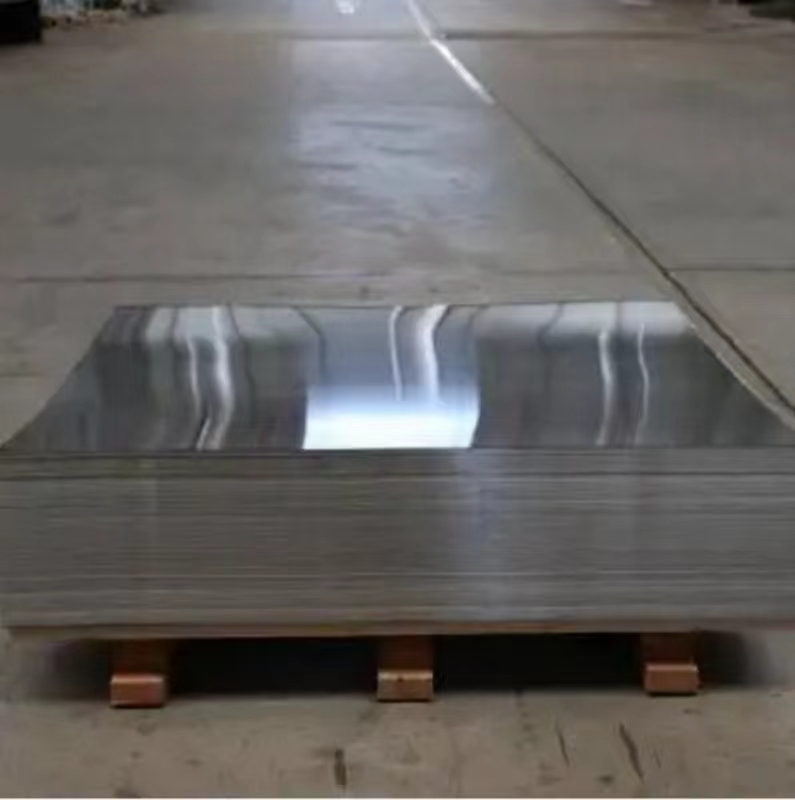

The process starts with the selection of raw materials. Most small metal tool boxes are made from high-quality steel or aluminum, ensuring their strength and longevity. The choice of material also influences the box's weight and portability, key factors for the end user. In this factory, dedicated teams work on sourcing materials that not only meet industry standards but also adhere to environmental regulations.

Once the materials are selected, the design phase kicks in. Engineers and designers collaborate to create blueprints that optimize both functionality and aesthetics. Ergonomics play a significant role in the design process, ensuring that the tool boxes are easy to handle and use. Additionally, the trend toward custom designs is growing, with more clients seeking personalized tool boxes suited to their specific needs.

The Manufacturing Process

The manufacturing process of small metal tool boxes involves several stages, each requiring precision and skill. It begins with cutting the metal sheets into specific dimensions using advanced laser cutting machines. This method not only ensures accuracy but also reduces waste. Following the cutting stage, the metal pieces undergo bending and shaping processes, where skilled technicians use hydraulic presses to create the desired structures.

small metal tool boxes factory

Welding is another critical stage in the production of metal tool boxes. Manual and robotic welding techniques are employed to ensure strong joints and seamless finishes. This combination of technology and craftsmanship reflects the factory’s commitment to quality.

After the welding process, the tool boxes move on to surface finishing. This step is essential for enhancing durability and aesthetics. Various treatments, such as powder coating or anodizing, are applied to protect the metal from corrosion and improve its appearance. The color choices available allow consumers to select tool boxes that match their personal style or branding.

Quality Control

Quality control is an integral part of the manufacturing process in a small metal tool box factory. Each box undergoes rigorous testing to ensure that it meets the required strength, durability, and design specifications. From drop tests to weight-bearing evaluations, these assessments are crucial in preventing defects and ensuring customer satisfaction.

Additionally, the factory implements a feedback loop where insights from customers are used to improve design and manufacturing processes. This commitment to continuous improvement helps the factory stay competitive and cater to the ever-evolving needs of the market.

Conclusion

The world of small metal tool box manufacturing is a fascinating intersection of technology, craftsmanship, and creativity. From the selection of raw materials to the final quality checks, every step in the process is crucial in producing a product that is both functional and durable. As consumers continue to seek reliable storage solutions, the factories producing these metal tool boxes play an essential role in meeting those demands.

Ultimately, the commitment to quality, innovation, and customer satisfaction ensures that small metal tool boxes remain an indispensable tool for craftsmen, hobbyists, and professionals alike. As we look to the future, advancements in technology and sustainable practices will likely shape this industry, paving the way for even more innovative designs and efficient manufacturing processes. The small metal tool box factory stands as a testament to human ingenuity and the relentless pursuit of excellence in craftsmanship.

-

Affordable Mini EV Cars | Eco-Friendly Electric Vehicles for City Life

NewsJul.20,2025

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025